Device for taking out greenware from rotary kiln

A rotary kiln and rotary disc technology, applied in the field of ceramic processing, can solve the problems of conveyor belt damage, discomfort, etc., and achieve the effect of convenient use, high efficiency and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

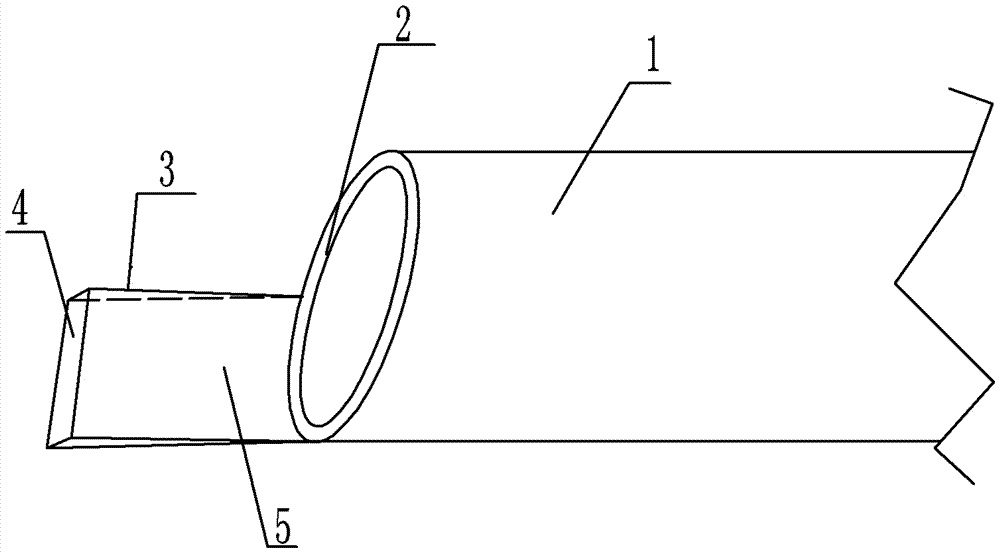

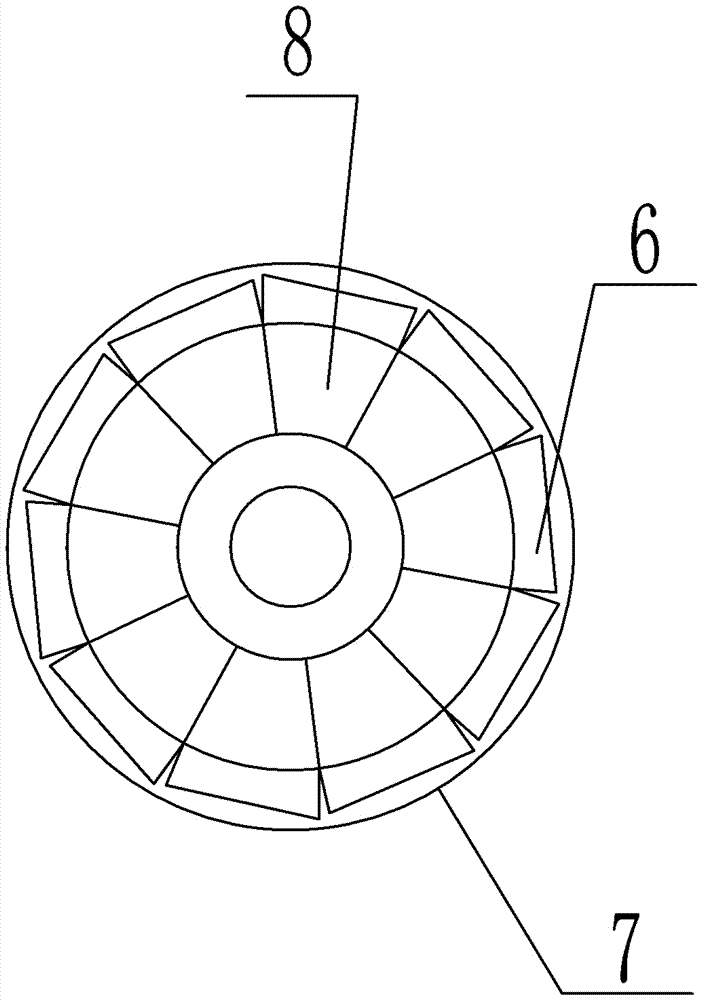

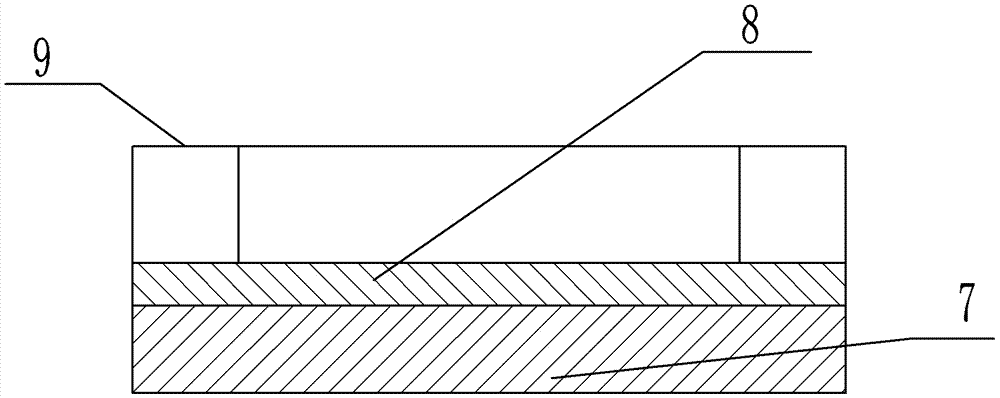

[0022] The reference signs in the drawings of the description include: 1 discharge pipe, 2 discharge door, 3 insert piece, 4 first slope, 5 second slope, 6 top block, 7 rotary disc, 8 ring piece, 9 partition, 10 compression springs.

[0023] The embodiment is basically as attached figure 1 , 2 , 3 and 4 show:

[0024] Embodiment After the rotary kiln has processed the pottery blank, the rotary disc 7 of the rotary kiln is in a rotating state, and an annular piece 8 is arranged on the upper part of the rotary kiln 7, and a top block 6 is arranged on the outer edge of the annular piece 8, and the discharge pipe 1 is provided with The discharge door 2 is provided with an insert 3 near the end of the rotary disk 7. The surface of the insert 3 has a first inclined plane 4 and a second inclined plane 5. The length of the first inclined plane 4 is less than the length of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com