Intelligent variable-frequency hydro-electric actuator capable of achieving 60-millimeter straight-stroke power failure resetting

An electric actuator, power-off reset technology, applied in the direction of engine components, valve details, valve operation/release devices, etc., can solve problems such as valve failure to open, insufficient opening stroke, and product safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those of ordinary skill in the art to better understand the technical solutions of the present invention, the technical solutions of the present invention will be further described below with reference to the accompanying drawings and embodiments.

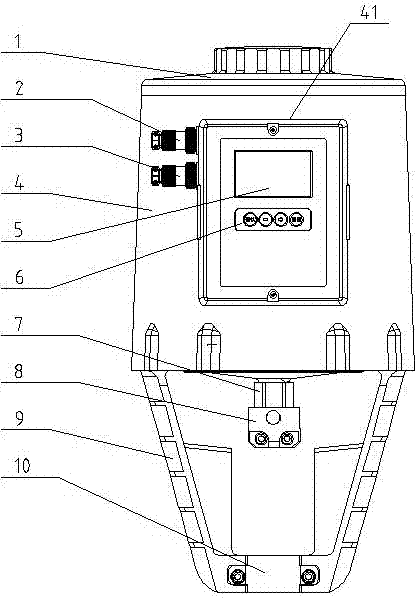

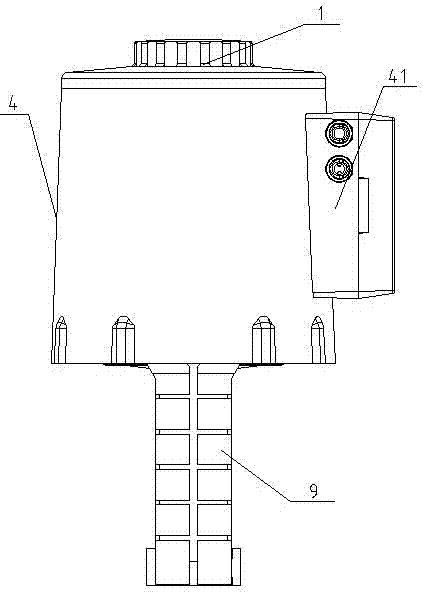

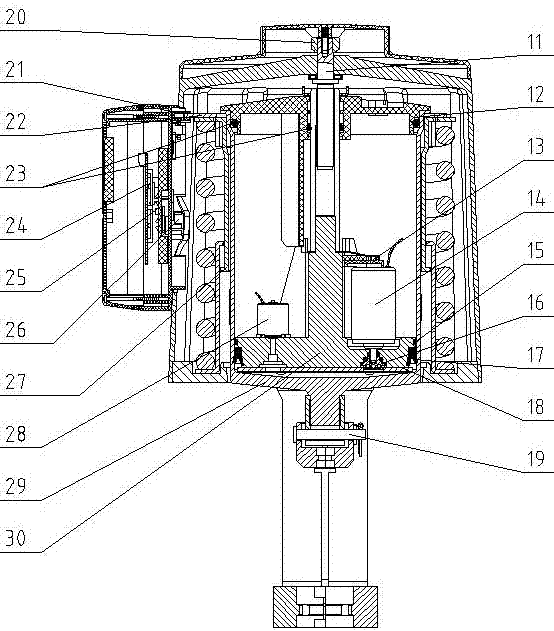

[0038] Reference attached Figure 1-14 As shown in the intelligent hydraulic valve actuator, the valve actuator includes an outer cylinder 4, a bracket 9 and a controller 41. The top of the outer cylinder 4 is provided with a top cover 1, and the upper end of the top cover 1 is additionally provided with an alarm indicator 44 , The alarm indicator 44 can display various faults and play the role of alarm and early warning. The alarm indicator 44 includes an LED lamp and a lampshade. The top cover 1 is provided with a screw 11 downwards at the center position. The screw 11 functions: 1, Adjust the initial position of the inner cylinder 29. 2. Adjust the distance between the universal joint 8 and the valve to fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com