Vibration reduction belt wheel

A technology of pulleys and pulleys, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of life loss of rubber layer, impact of pulley running accuracy and life, impact of pulley transmission accuracy, etc. , to avoid accelerated aging, improve smooth operation and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

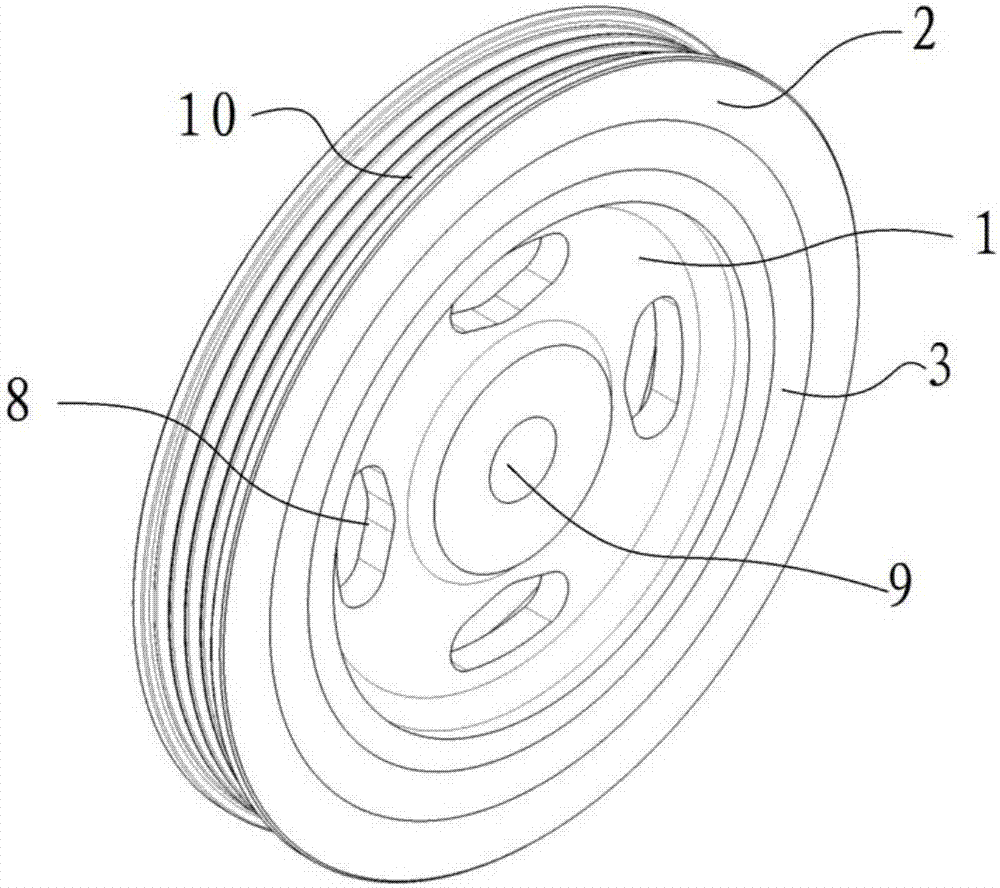

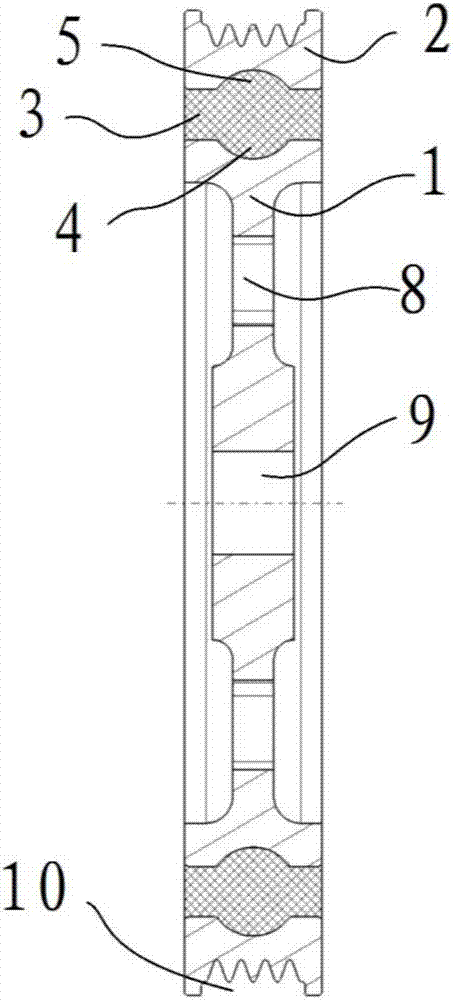

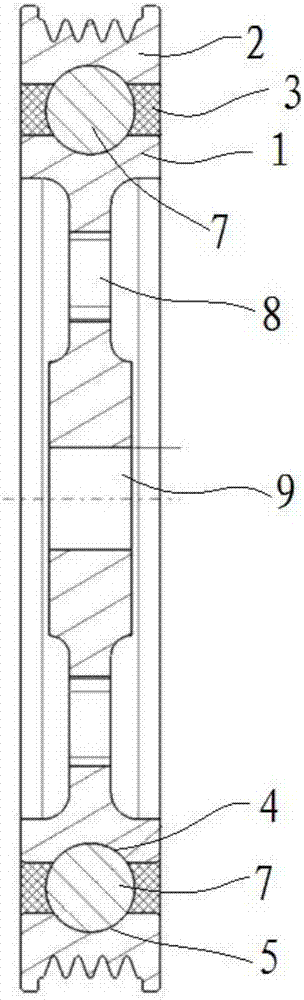

[0020] like Figure 1 to Figure 5 As shown, the embodiment of the present invention provides a vibration-damping pulley, including an inner pulley 1 provided with a shaft hole 9, an outer pulley 2 provided with a belt groove 10 on the outer circumference, and an outer pulley 2 arranged on the inner belt The rubber layer 3 between the wheel 1 and the outer pulley 2, the inner pulley 1, the outer pulley 2 and the rubber layer 3 are coaxially arranged, the shaft hole 9 is provided with a keyway, and the inner pulley 1 It is fixedly connected with the crankshaft in the way of key and keyway, the belt loop is set in the belt groove 10, and the power is output to the external device. The outer peripheral surface of the inner pulley 1 is provided with a first arc-shaped groove 4. The inner circumfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com