Drainage tunnel stand pipe planting construction device and method

A technology for drainage tunnels and construction devices, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of long construction period, occupation of key line construction period, low construction safety, etc., so as to shorten construction period and improve construction efficiency. , Improve the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] specific implementation plan

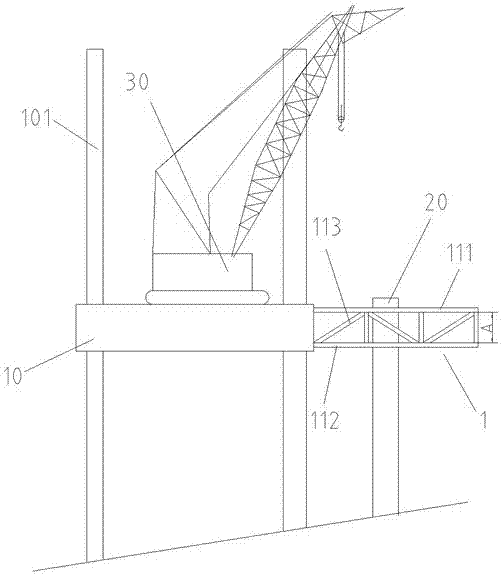

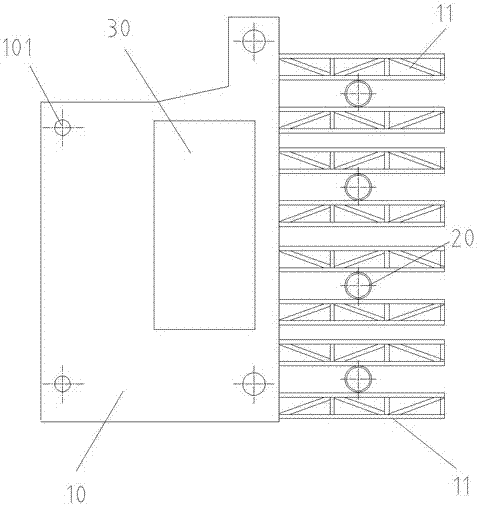

[0056] The present invention will be further described below in conjunction with the accompanying drawings and the embodiment of the drain riser pipe planting of No. 1 and No. 2 unit drainage works of Lufeng Nuclear Power Plant. Such as image 3 As shown, there are 8 standpipes 40 in the drainage heads of Units 1 and 2 of Lufeng Nuclear Power Plant, and the positioning and fixing of 4 riser pipes 40 can be completed in sequence for the "Changxu" ship platform 10 once anchored. 10 After moving the ship's position once, complete the positioning and fixing of the other four risers 40 .

[0057] Such as figure 1 and figure 2 As shown, the construction device of the present invention includes the "Changxu" ship platform 10 supported by four liftable hydraulic props 101. The displacement of the "Changxu" ship platform 10 is 1510t, and its wind resistance is 15m / s when it is working. (level 7), 44m / s (level 12) when not working. Its anti-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com