A method for strengthening anoxic-aerobic-sedimentation-anaerobic process sludge reduction

A sludge reduction and process technology, applied in aerobic and anaerobic process treatment, chemical instruments and methods, biological sludge treatment, etc., to achieve energy saving, sludge reduction effect improvement, and sludge reduction effect increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

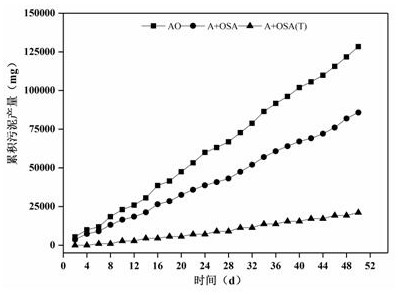

[0028] The experimental sludge was taken from the aerobic section of the traditional AAO process of Chongqing Jiguanshi Wastewater Treatment Plant. The pool is 6000mg / L.

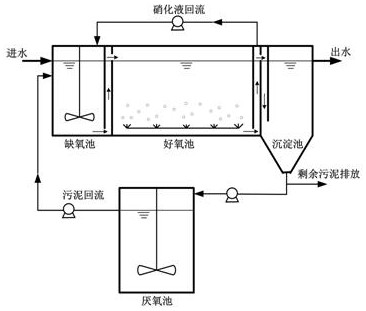

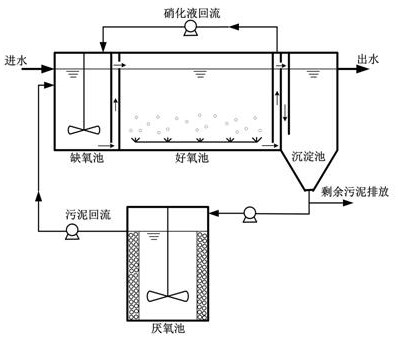

[0029] A method of strengthening anoxic-aerobic-precipitation-anaerobic process sludge reduction in the present invention, such as figure 1 shown, including the following steps:

[0030] (1) Add a stirring device and a packing device to the anaerobic tank of the A+OSA process. The packing device is an annular space surrounded by two cylindrical stainless steel concentric mesh cylinders; add internal multi-fold spherical Polypropylene material, the filling ratio is controlled to 20%; the outflow pipe is set at the corresponding position of the anaerobic pool wall and led to the upper part of the anoxic pool;

[0031] (2) The sewage is introduced into the anoxic tank to provide carbon source for denitrification; the sewage flows into the aeration tank for aerobic treatment and nitrification process, and the ...

Embodiment 2

[0035] The experimental sludge was taken from the aerobic section of the traditional AAO process of Chongqing Jiguanshi Wastewater Treatment Plant. The pool is 6000mg / L.

[0036] A method of strengthening anoxic-aerobic-precipitation-anaerobic process sludge reduction in the present invention, such as figure 1 shown, including the following steps:

[0037] (1) Add a stirring device and a packing device to the anaerobic tank of the A+OSA process. The packing device is an annular space surrounded by two cylindrical stainless steel concentric mesh cylinders; add internal multi-fold spherical Polypropylene material, the filling ratio is controlled to 20%; the outflow pipe is set at the corresponding position of the anaerobic pool wall and led to the upper part of the anoxic pool;

[0038] (2) The sewage is introduced into the anoxic tank to provide carbon source for denitrification; the sewage flows into the aeration tank for aerobic treatment and nitrification process, and the ...

Embodiment 3

[0042] The experimental sludge was taken from the aerobic section of the traditional AO process of Chongqing Jiguanshi Sewage Treatment Plant. The pool is 6000mg / L.

[0043] A method of strengthening anoxic-aerobic-precipitation-anaerobic process sludge reduction in the present invention, such as figure 1 shown, including the following steps:

[0044] (1) Add a packing device to the anaerobic tank of the conventional A+OSA process. The packing device is an annular space surrounded by two cylindrical stainless steel concentric mesh cylinders; add inner multi-folded spherical polypropylene between the two mesh cylinders material, control the filling ratio to 25%; open holes at the corresponding positions on the wall of the anaerobic tank to set the outlet pipe, and lead it to the upper part of the anoxic tank;

[0045] (2) The sewage is introduced into the anoxic tank to provide carbon source for denitrification; the sewage flows into the aeration tank for aerobic treatment an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com