a lifting device

A lifting device and suit technology, applied in cranes, hoisting devices, hoisting equipment braking devices, etc., can solve problems such as frequent changes in lifting frequency, unstable lifting of heavy objects, and prone to accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

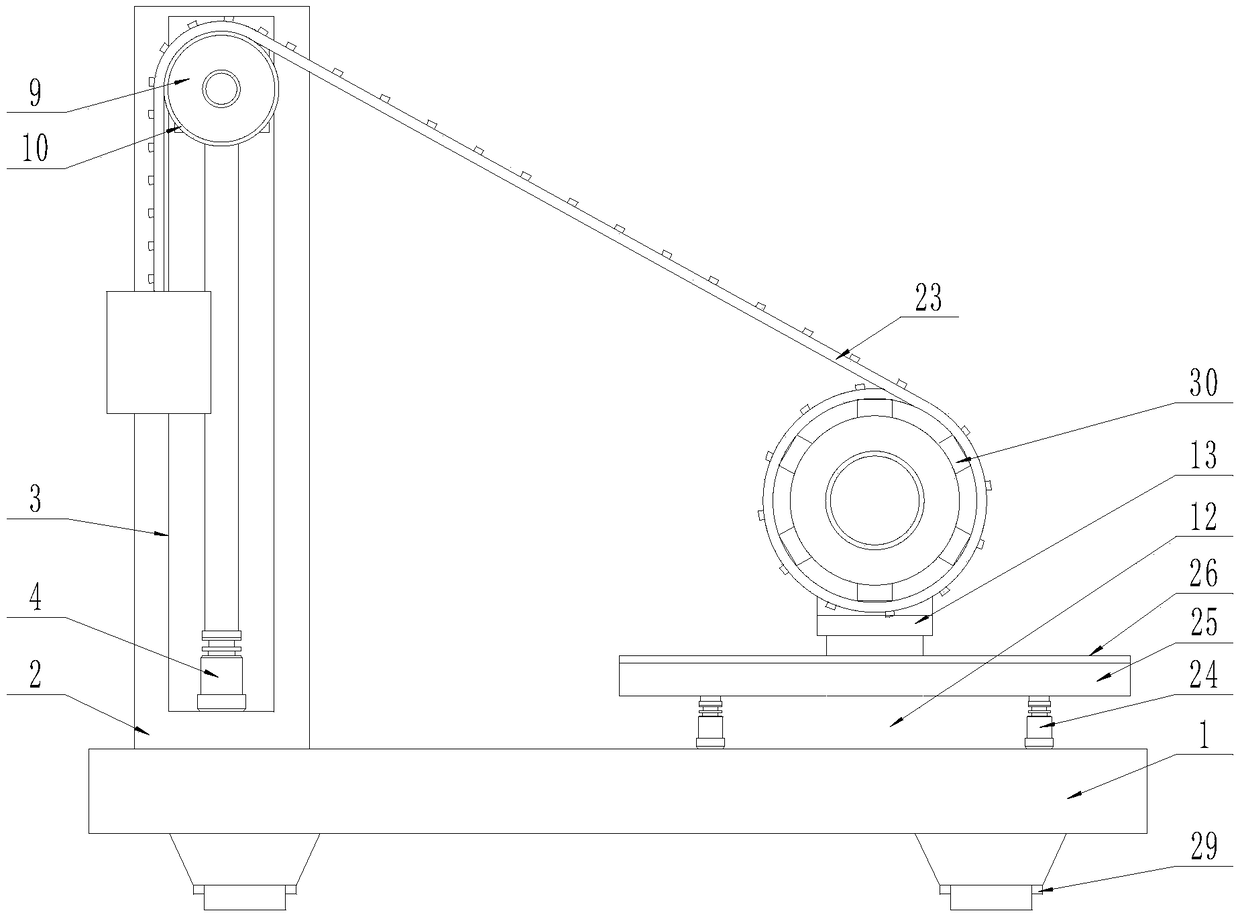

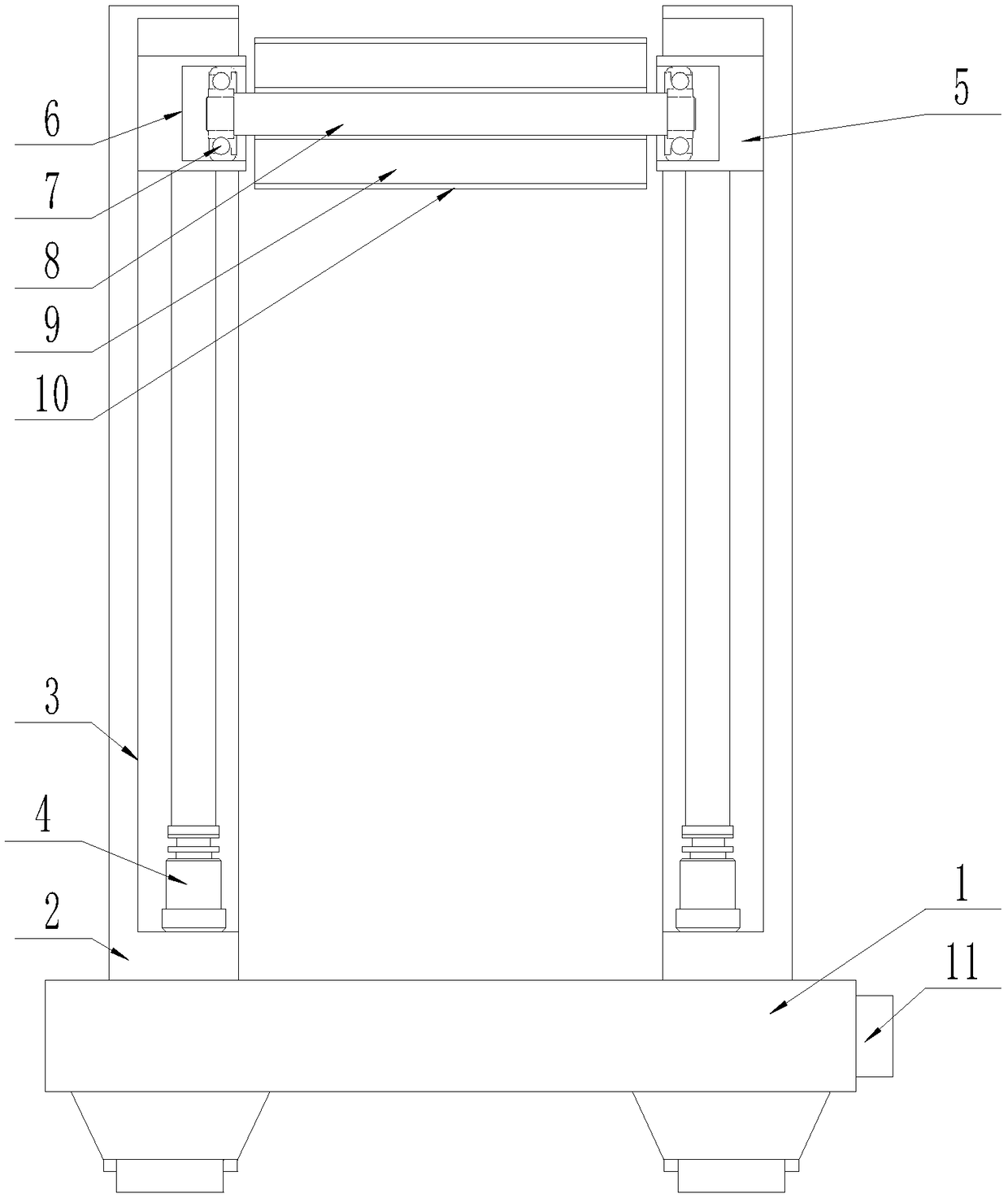

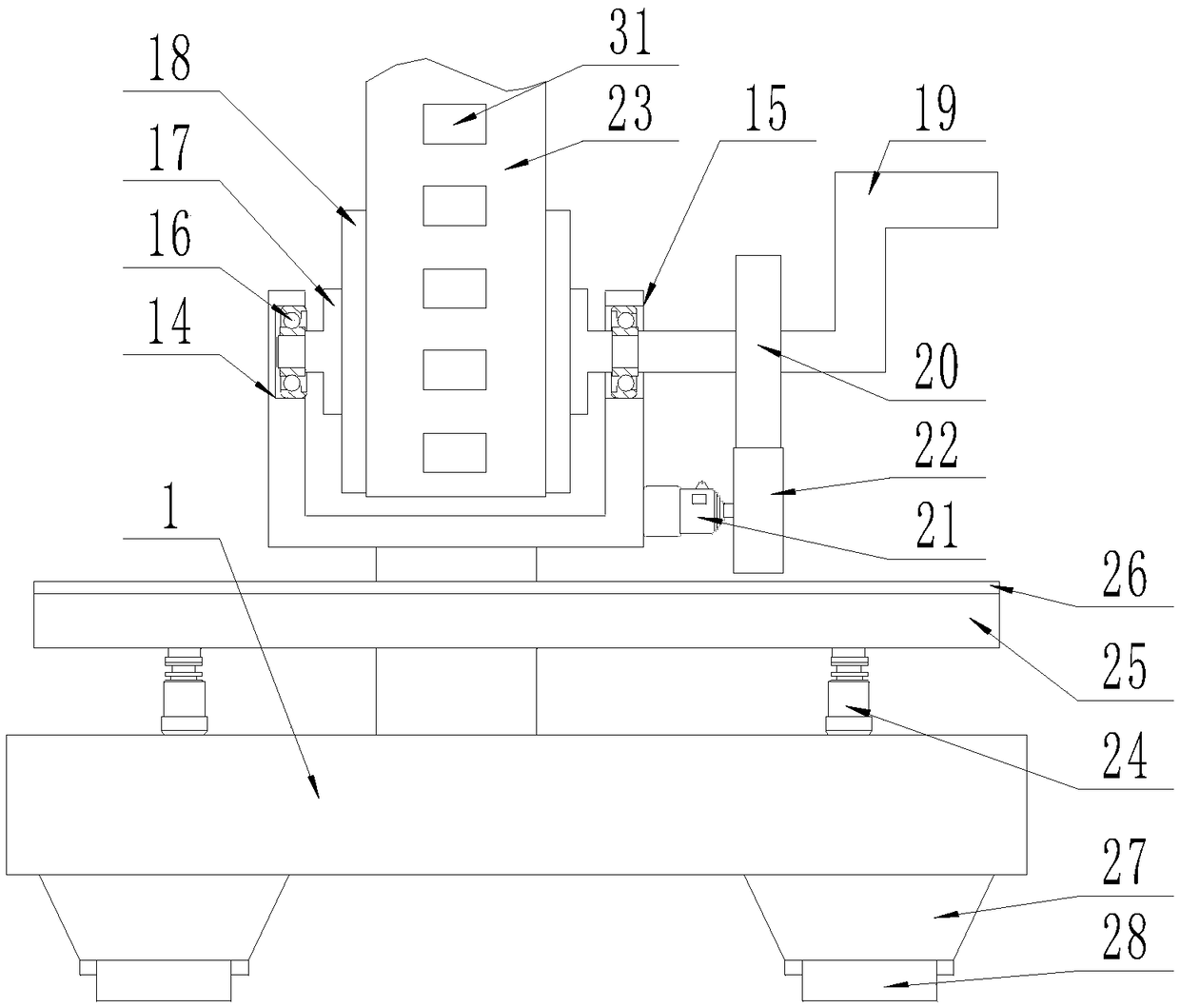

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, a lifting device includes a base 1, a support mechanism, a lifting mechanism and a safety protection mechanism are provided on the upper surface of the base 1, and a fixed installation mechanism is provided on the lower surface of the base 1, and the support mechanism is A group of uprights 2 arranged on the upper surface of the base 1, rectangular slots 3 respectively opened on opposite side surfaces of a group of uprights 2, a telescopic motor-4 arranged on the inner lower surface of the rectangular slot 3, and a telescopic motor 4. The lifting block 5 at the telescopic end, the circular groove 6 opened on the opposite side surfaces of the lifting block 5, the bearing 7 arranged in the circular groove 6, the rotating rod 8 inserted in a group of bearings 7, and the sleeve The lifting shaft 9 on the rotating rod 8 and the anti-skid sleeve 10 sleeved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com