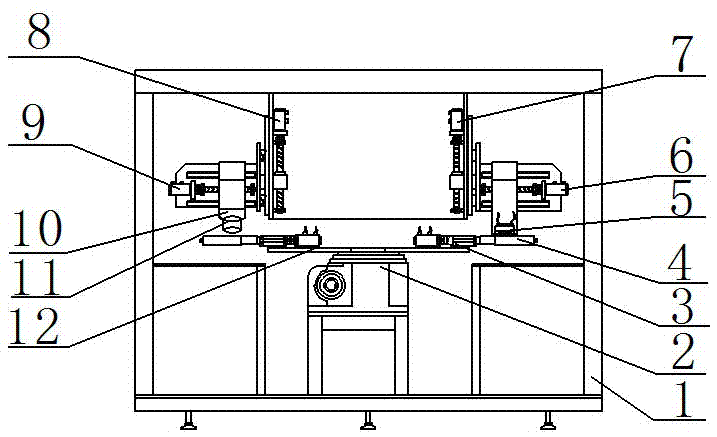

Full-automatic six-color-and-sixteen-station complex curved surface digital rotary printing and testing integrated machine

A complex curved surface and digital printing technology, applied in printing, typewriters, etc., can solve problems such as unstable printing quality and slow printing speed, and achieve good results, convenient bottle replacement, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

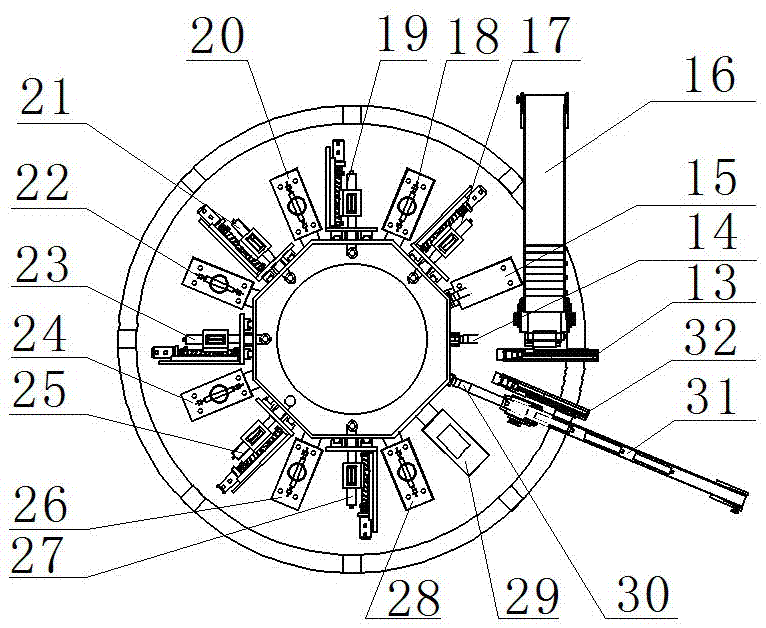

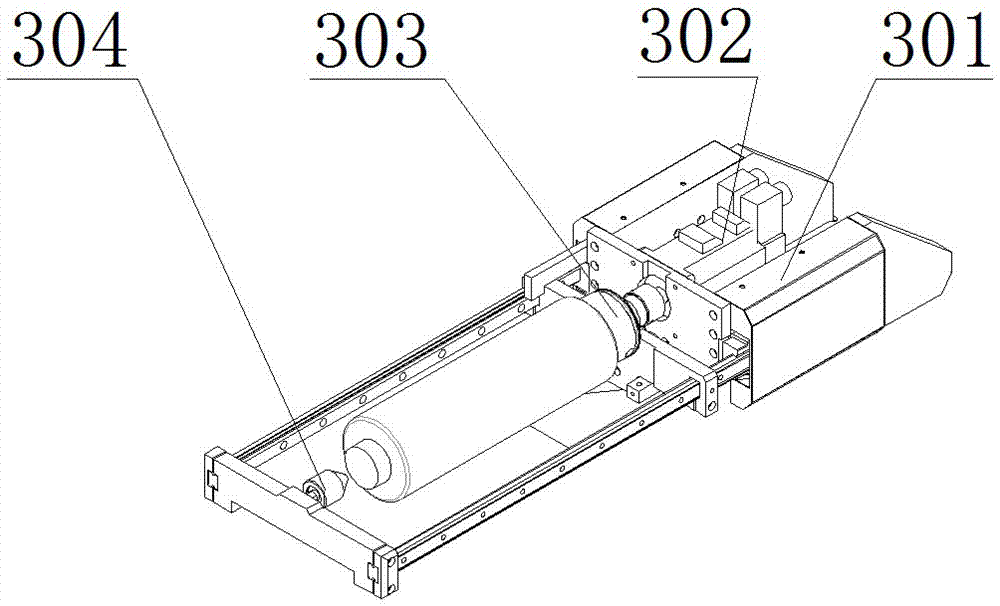

[0043] refer to Image 6 , Figure 7 , digital printing of elliptical bottles: the operator puts the elliptical bottle on the feeding conveyor belt 16, and the feeding conveyor belt 16 transports the elliptical bottle to the position where the feeding manipulator 13 clamps the bottle, and the feeding manipulator 13 clamps the elliptical bottle and transposes it. Rotate 90 degrees clockwise, and then sent to the product loading level 14 by the servo motor, the tooling position clamps the cylinder to clamp the oval bottle, the divider 2 starts to drive the product to rotate clockwise from the loading level 14 to the surface treatment position by 22.5 degrees 15. Start the surface treatment system to treat the outer surface of the elliptical bottle. Start the divider 2 to drive the elliptical bottle to rotate 22.5 degrees clockwise and then shift to the No. 1 color printing position 17. The digital printing device moves the servo motor 7 vertically Vertically descend until it is...

Embodiment example 2

[0045] refer to Figure 8 , Figure 9, Digital printing of special-shaped bottles: the operator puts the special-shaped bottle on the feeding conveyor belt 16, and the feeding conveyor belt 16 transports the special-shaped bottle to the position where the feeding manipulator 13 clamps the bottle, and the feeding manipulator 13 clamps the special-shaped bottle and transposes, Rotate clockwise by 90 degrees, and then sent to the product loading level 14 by the servo motor, the tooling position clamps the cylinder to clamp the special-shaped bottle, the divider 2 starts to drive the product to rotate clockwise from the loading level 14 to the surface treatment position by 22.5 degrees 15. The surface treatment system is started to treat the outer surface of the special-shaped bottle. The divider 2 drives the special-shaped bottle to rotate clockwise for 22.5 degrees and then shifts to the No. 1 color printing position 17. The digital printing device moves the servo motor 7 vertic...

Embodiment example 3

[0047] refer to Figure 10 , Figure 11 , Digital printing of spherical products: the operator puts the spherical products on the feeding conveyor belt 16, and the feeding conveyor belt 16 transports the spherical products to the position where the feeding manipulator 13 clamps the bottle, and the feeding manipulator 13 clamps the spherical product and transposes, Rotate clockwise by 90 degrees, and then sent to the product loading level 14 by the servo motor, the tooling position clamps the cylinder to clamp the spherical product, and the divider 2 starts to drive the product to rotate clockwise from the loading level 14 to the surface treatment position by 22.5 degrees 15. The surface treatment system is started to treat the outer surface of the spherical product. The divider 2 is started to drive the spherical product to turn 22.5 degrees clockwise and then shift to the No. 1 color printing position 17. The digital printing device moves the servo motor 7 vertically. Vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com