Hot rolled strip steel welding seam quality testing apparatus and hot rolled strip steel welding seam quality testing method

A technology for quality inspection and hot-rolled strip steel, applied to measuring devices, instruments, scientific instruments, etc., can solve problems such as low safety, irregular punching, and incomplete bending, so as to ensure safety and improve effectiveness , the effect of improving efficacy and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

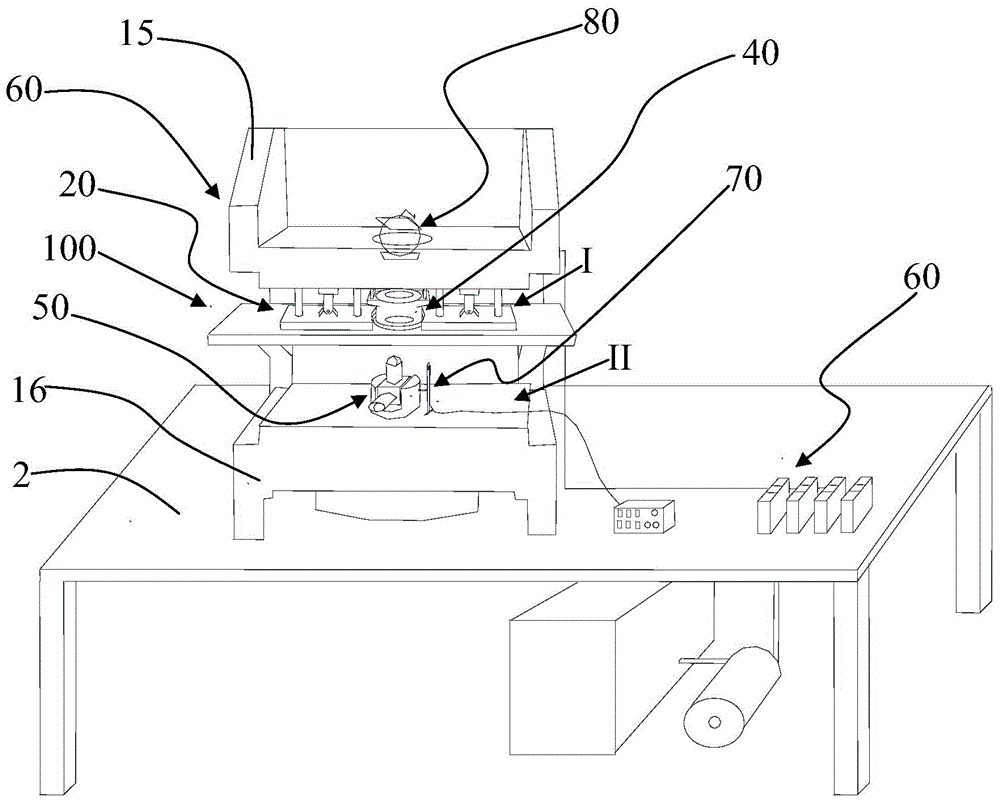

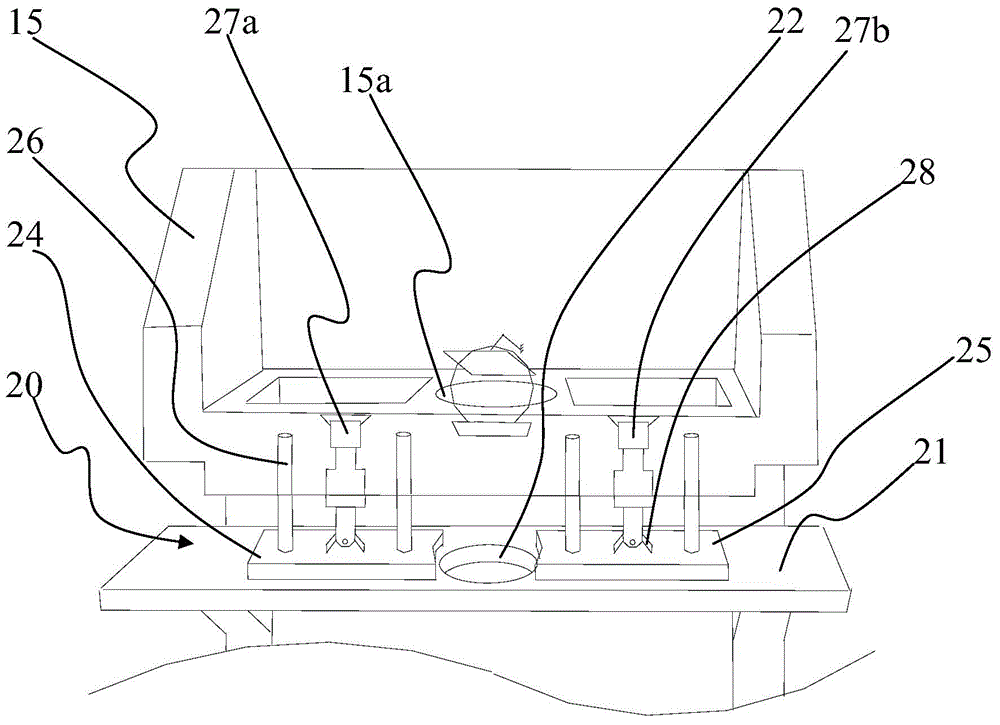

[0032] In order to make the above-mentioned objects, features and advantages of the present invention more obvious and understandable, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. First, it should be noted that the present invention is not limited to the following specific embodiments. Those skilled in the art should understand the present invention from the spirit embodied in the following embodiments. Various technical terms can be optimized based on the spirit of the present invention. Broad understanding. The same or similar components in the figures are represented by the same reference numerals.

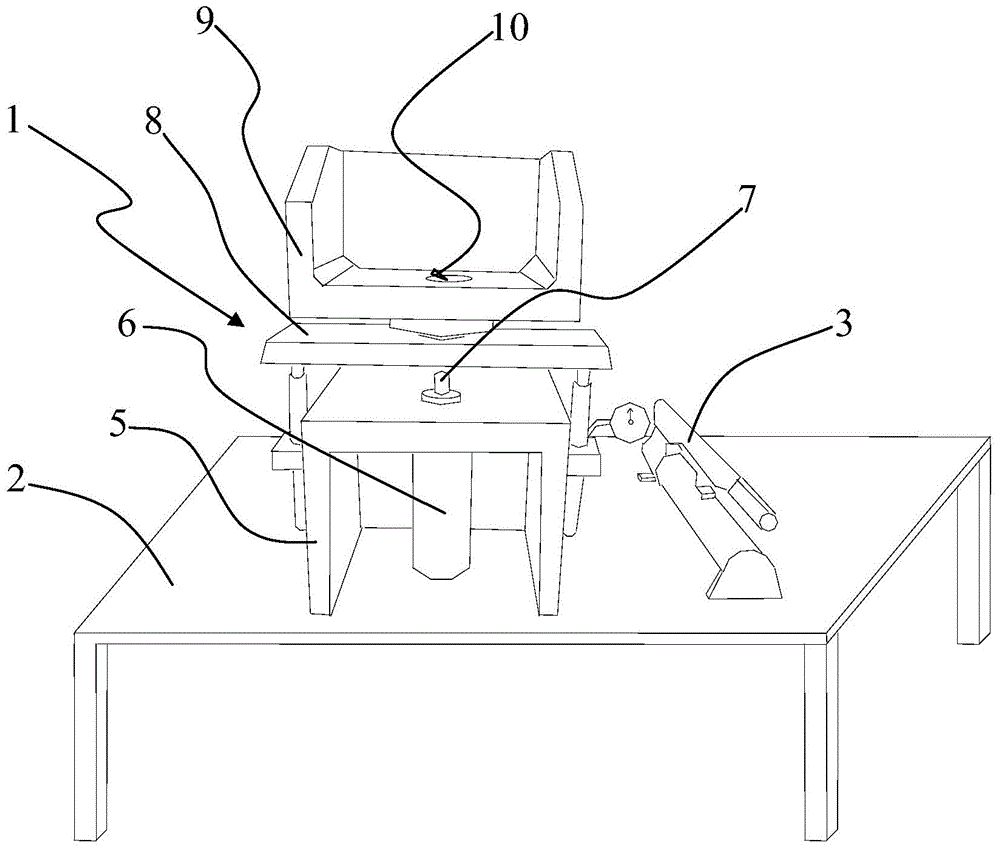

[0033] Such as Figure 2 to Figure 7 A welding seam quality inspection device for hot rolled strip steel (hereinafter referred to as the inspection device) according to an embodiment of the present invention is shown. As shown in the figure, the inspection device 100 is placed on a metal table 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com