Novel material grinding tool

An abrasive and abrasive technology, applied in the field of new abrasives, can solve problems such as affecting the health of workers, difficulty in improving abrasive efficiency, and difficulty in grinding and smoothing materials, achieving long service life, improving efficiency, and preventing rigid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

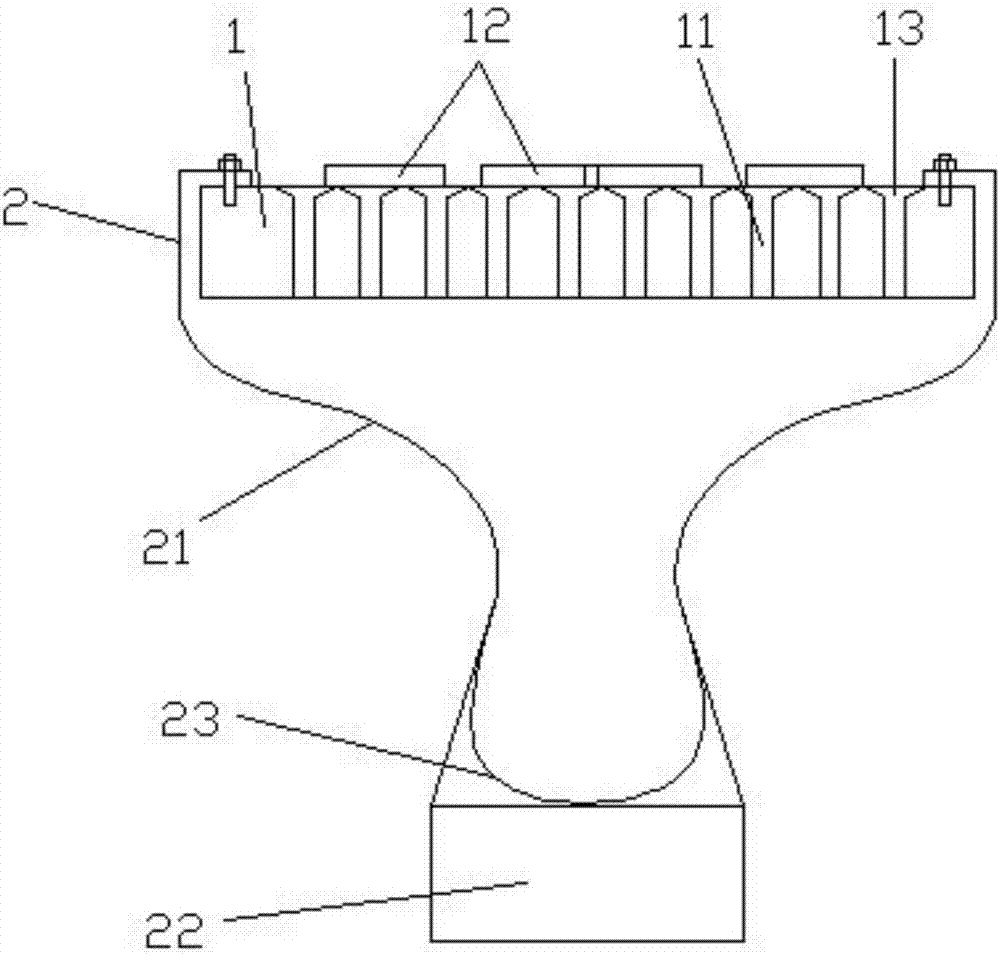

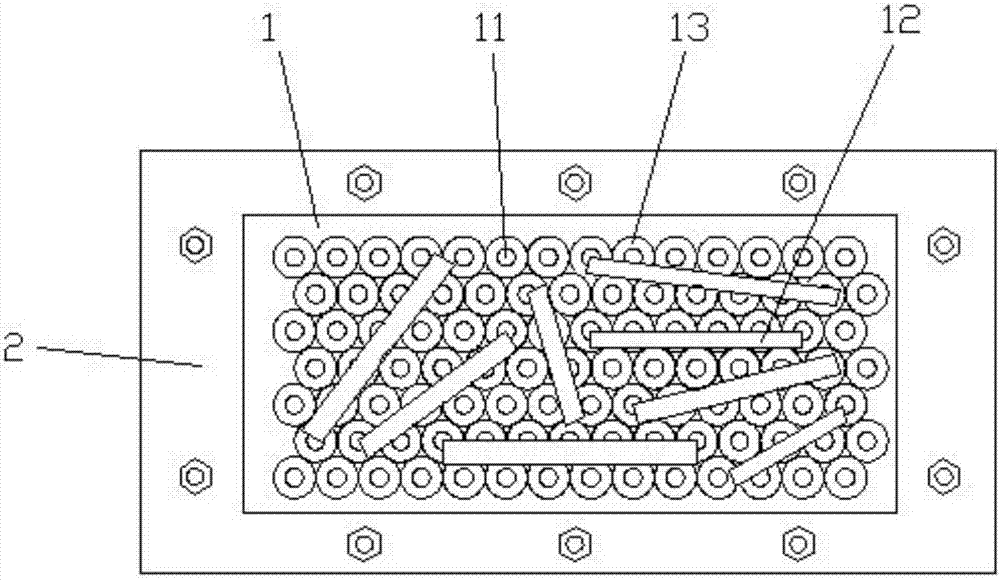

[0020] The purpose of this embodiment is in order to provide a kind of novel abrasive grinding tool, as figure 1 and figure 2 As shown, the abrasive tool includes a cuboid-shaped abrasive plate 1, and a dust suction device arranged below the abrasive plate; the abrasive plate 1 is longitudinally provided with a number of through holes 11, and the upper part of the abrasive plate is integrally formed with the abrasive plate. A plurality of abrasive ribs 12, above each through hole is provided with a conical dust suction funnel 13, and the adjacent dust suction funnel is arranged tangentially; The hard plastic connecting edge 2 connected by the upper edge of the screw rod, the rounded table-shaped hard dust collecting funnel 21 connected to the lower edge of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com