Bottle washing device

A technology of bottle and brush cleaning mechanism, which is applied in the direction of drying gas arrangement, cleaning hollow objects, dryers, etc., which can solve the problems of poor cleaning effect and high labor intensity, and achieve the goals of reducing labor costs, preventing deviation, and ensuring stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

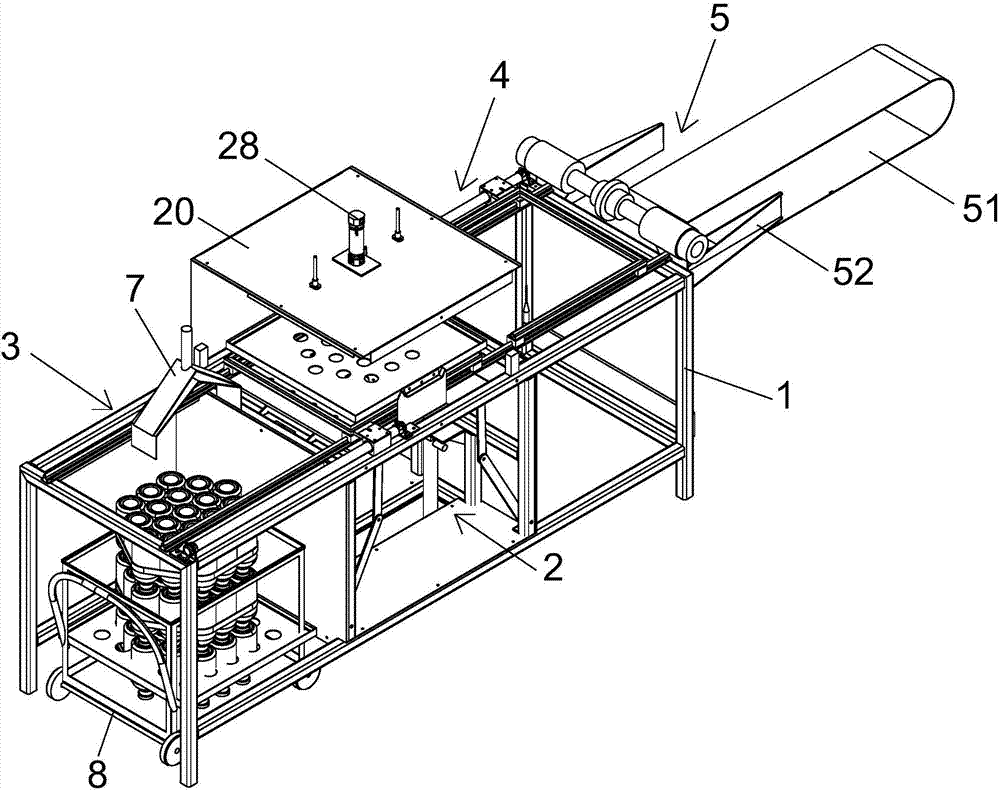

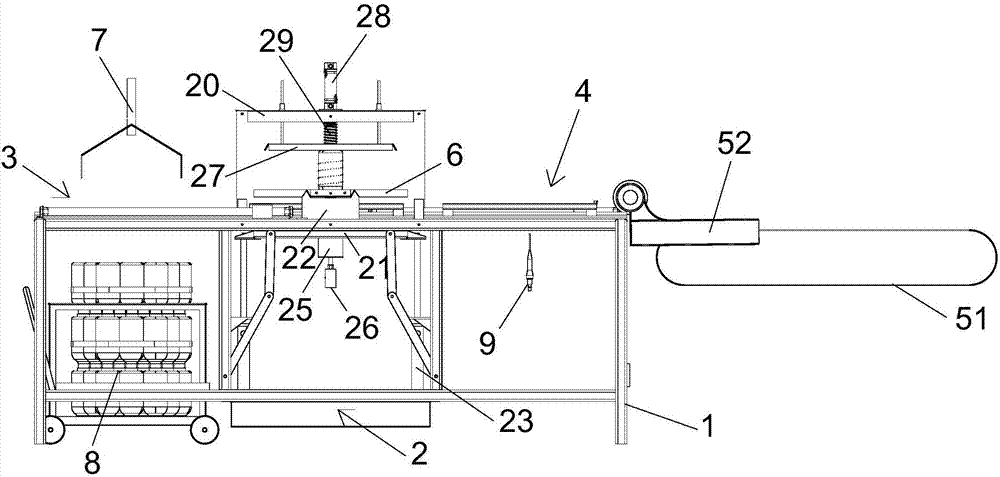

[0019] Such as Figure 1 to Figure 6 Shown is a schematic diagram of an embodiment of a bottle scrubbing device provided by the present invention.

[0020] A bottle scrubbing device, which includes a frame 1, a scrubbing mechanism 2 arranged in the middle of the frame 1, and conveying mechanisms located on both sides of the scrubbing mechanism 2.

[0021] The conveying mechanism includes a bottle inlet assembly 3 located on the left side of the scrubbing mechanism 2, a bottle outlet assembly 4 located on the right side of the scrubbing mechanism 2, and several pallets 6 for placing bottles. The bottom surface of the pallet 6 is provided with a number of corresponding inverted The through hole 61 of bottle mouth.

[0022] Before cleaning, workers bind the bottles into cleaning bottle groups arranged in a fixed way th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com