Intelligent production system

An intelligent production and management system technology, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve problems such as inaccurate efficiency control, affecting product production, and low statistical accuracy, so as to improve production management horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

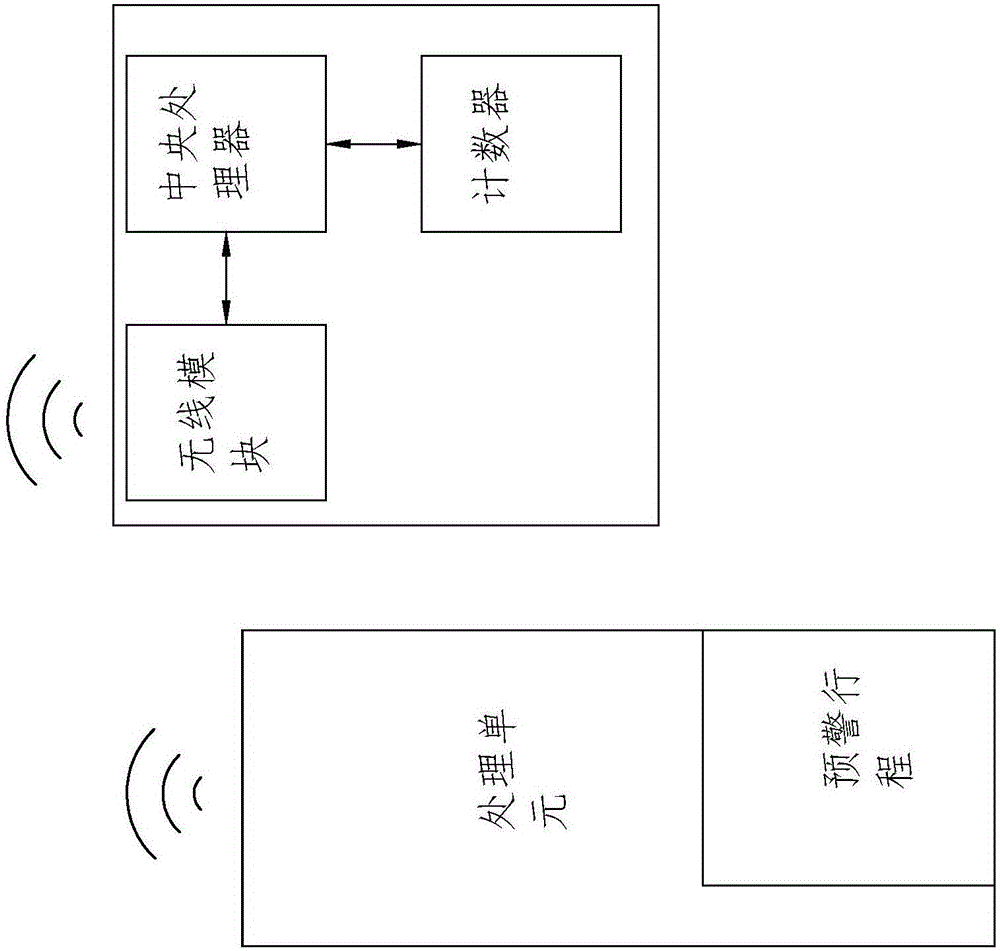

[0018] Embodiment 1, reference figure 1 , an intelligent production system, comprising: a workbench and a management system, the management system comprising: a processing unit, a counter, a central processing unit and a wireless module, and the counter, the central processing unit and the wireless module are all arranged on the workbench.

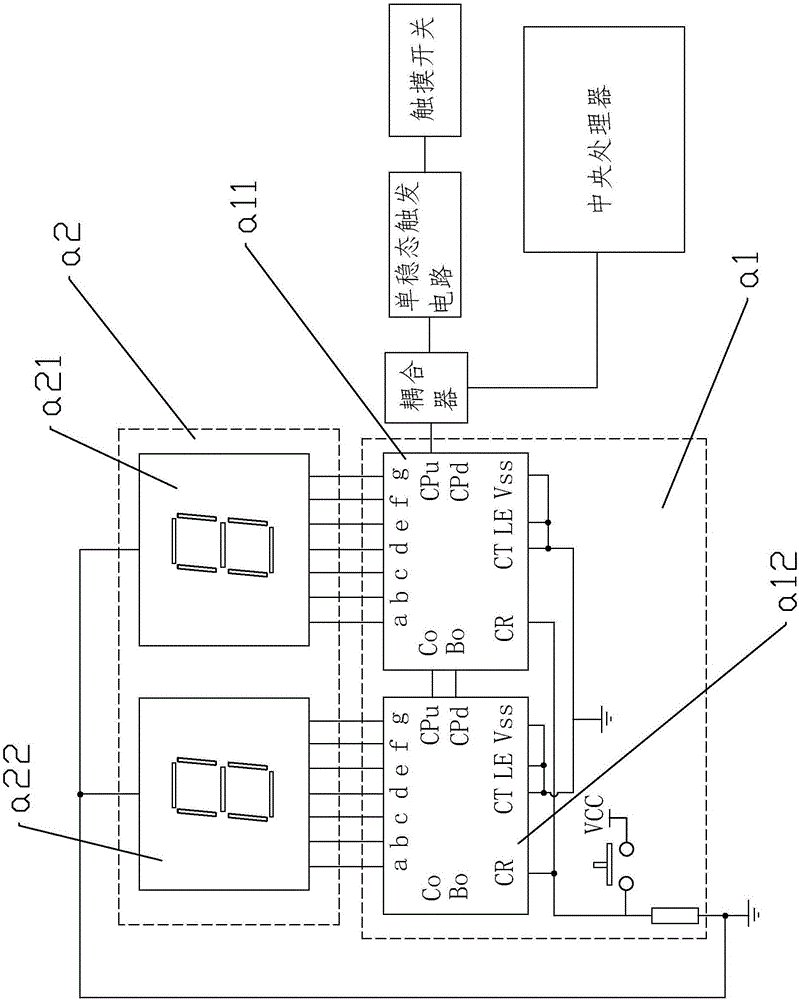

[0019] combine figure 2 , the counter includes a counting display circuit a1, a display unit a2, a monostable trigger circuit, a touch switch, the counting display circuit a1 includes a first counting display chip a11 and a second counting display chip a12, the first and second counting The models of the display chips a11 and a12 are CD40110. The display unit a2 includes a first digital tube a21 and a second digital tube a22. The first and second digital tubes a21 and a22 are respectively connected with the first and second counting display chips The decoding terminal a-g of a12 is connected, and the first and second digital tubes a21 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com