Passenger car inspection tool pressing mechanism

A pressing mechanism and passenger car technology, applied in the direction of adopting mechanical devices, mechanical measuring devices, measuring devices, etc., can solve the problems affecting the accuracy of detection, etc., and achieve the effect of simple operation, novel structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the new invention will be further described below in conjunction with the accompanying drawings.

[0018] Such as Figure 1-3 As shown, the compression mechanism of the passenger car inspection tool includes a roof 1, and the roof sun visor hole 2 is arranged on the roof 1; it also includes a reference pressing assembly 3 and a reference block assembly 4; the reference The pressing assembly 3 presses the roof sun visor hole 2 on the roof 1 on the reference block assembly 4 .

[0019] The reference pressing assembly 3 includes a large tightening rod 5, a tightening rod screw 6, a small tightening rod 7 and a pressing plate 8; the large tightening rod 5 and the small tightening rod 7 are fixedly connected by the tightening rod screw 6, Threaded connection between the small tightening rod 7 and the pressing plate 8.

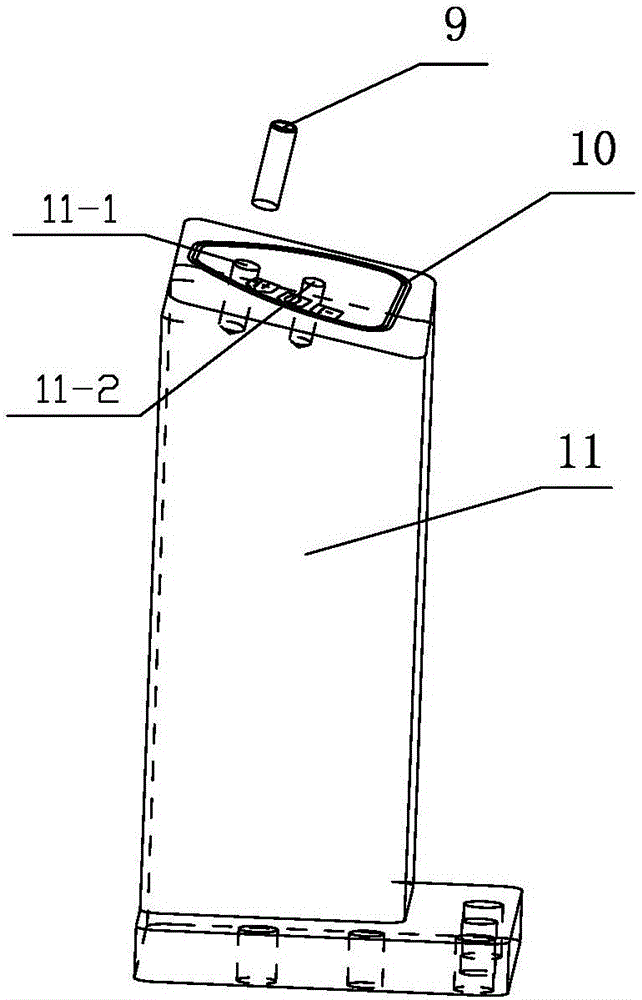

[0020] The reference block assembly 4 includes a positioning pin 9, a reference block reticle 10 and a reference block main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com