Push-pull three-dimensional garage

A three-dimensional garage and push-pull technology, which is applied to the buildings, building types, and buildings where cars are parked, can solve the problems of inefficient operation, high manufacturing, repair, and high maintenance costs, and save running time and maintenance costs. , the effect of saving energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

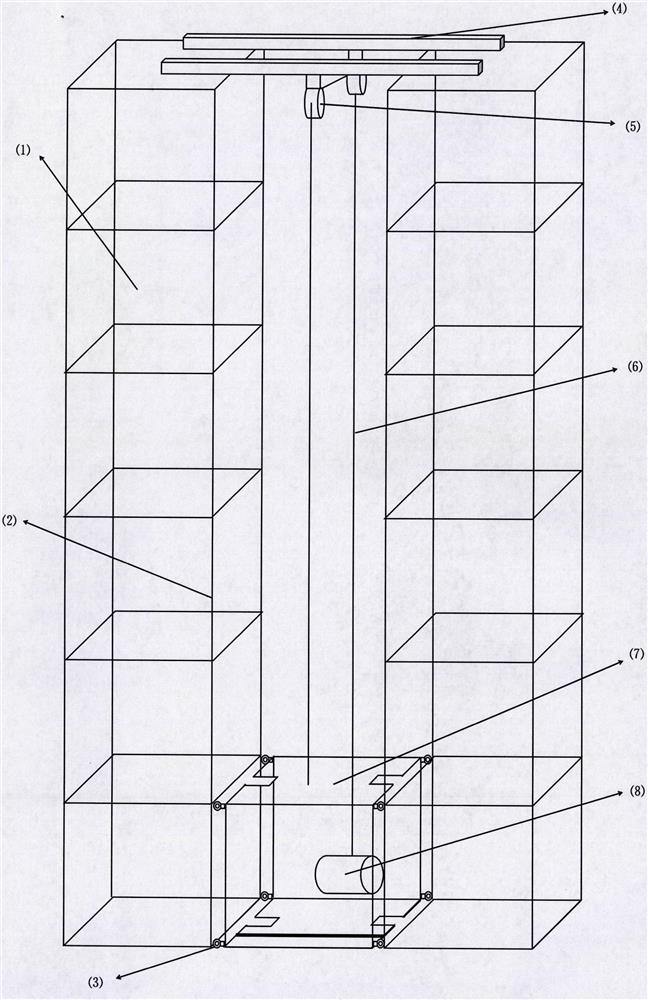

[0019] exist figure 1 Among them, the parking space (1) constitutes the main frame of the present invention, the lifting column (2) constitutes the lifting channel, the anti-collision roller (3) is located between the lifting column (2) and the lifting frame (7), and the hoist (8) is fixed in the lifting channel. On the ground outside the channel, one end of the wire rope (6) is fixed on the hoist (8), and the other end is fixed on the top platform around the fixed pulley (5). The beam (4) is located at the top of the lifting channel, and the fixed pulley (5) is installed on Below the beam (4).

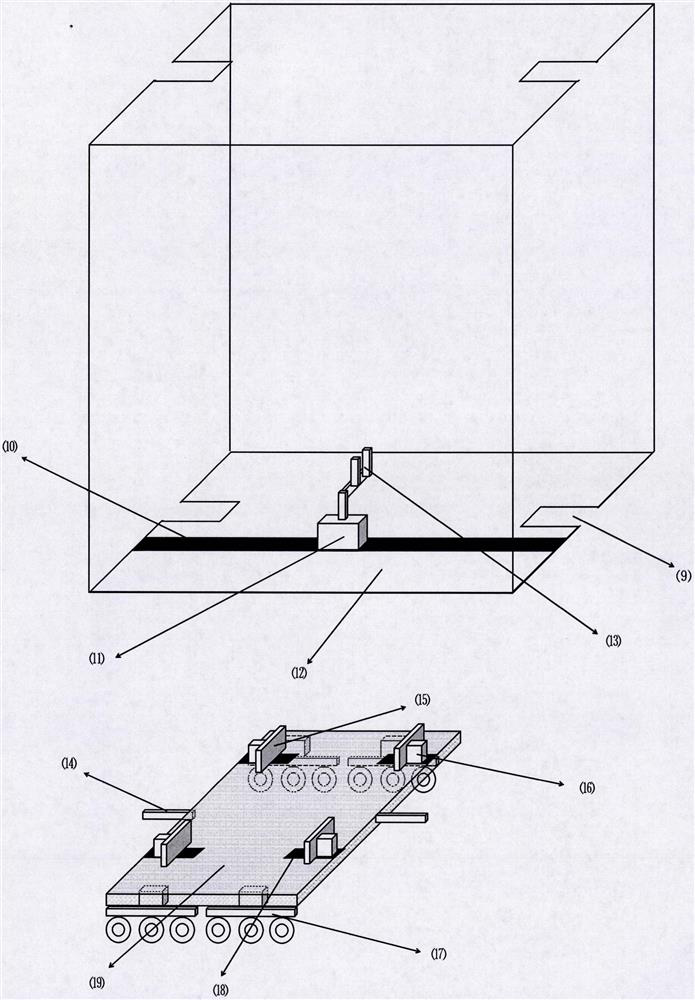

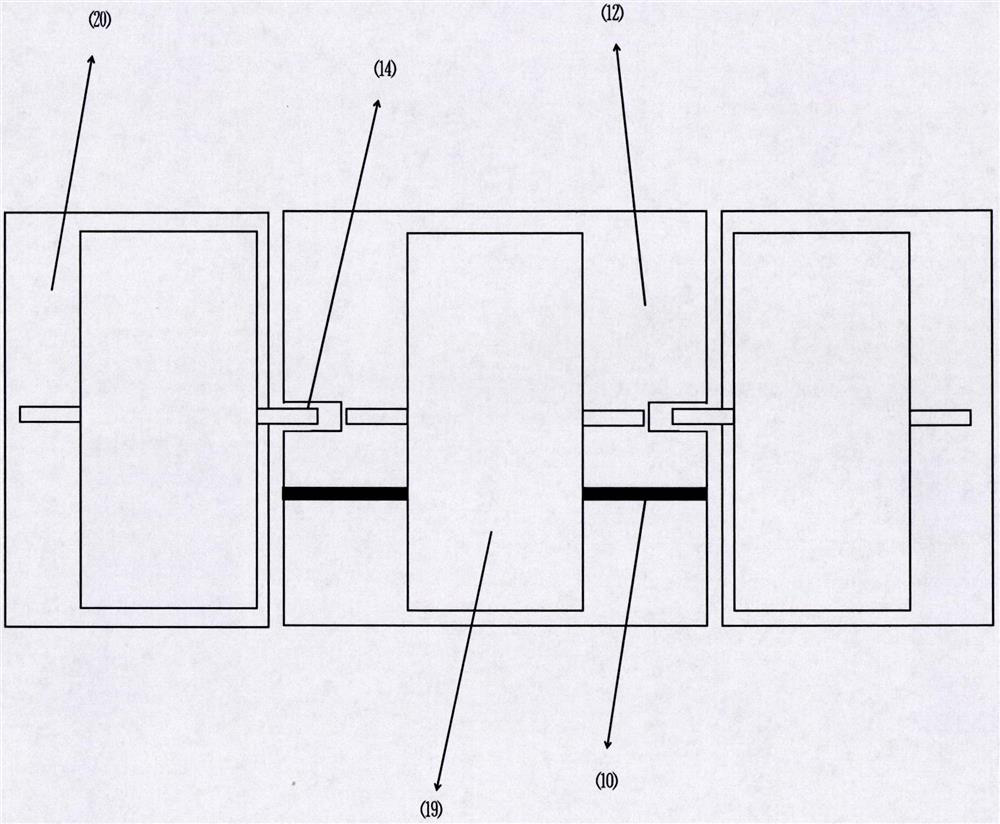

[0020] exist figure 2 , the notch (9) of the traverse platform is located on the lateral sides of the traverse platform (12), the push-pull guide rail (10) is fixed on the traverse platform (12), and the push-pull guide rail slider (11) is located on the push-pull guide rail (10) , There is a parking plate gripper (13) on the push-pull guide rail slider (11), the parking plate grab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com