A thin-layer wear-resistant ceramsite road construction machinery and equipment and construction method

A technology of pavement construction machinery and ceramsite, which is applied in the field of construction and construction, can solve problems such as increasing the complexity of the construction process, and achieve the effects of durable and bright colors, convenient construction and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

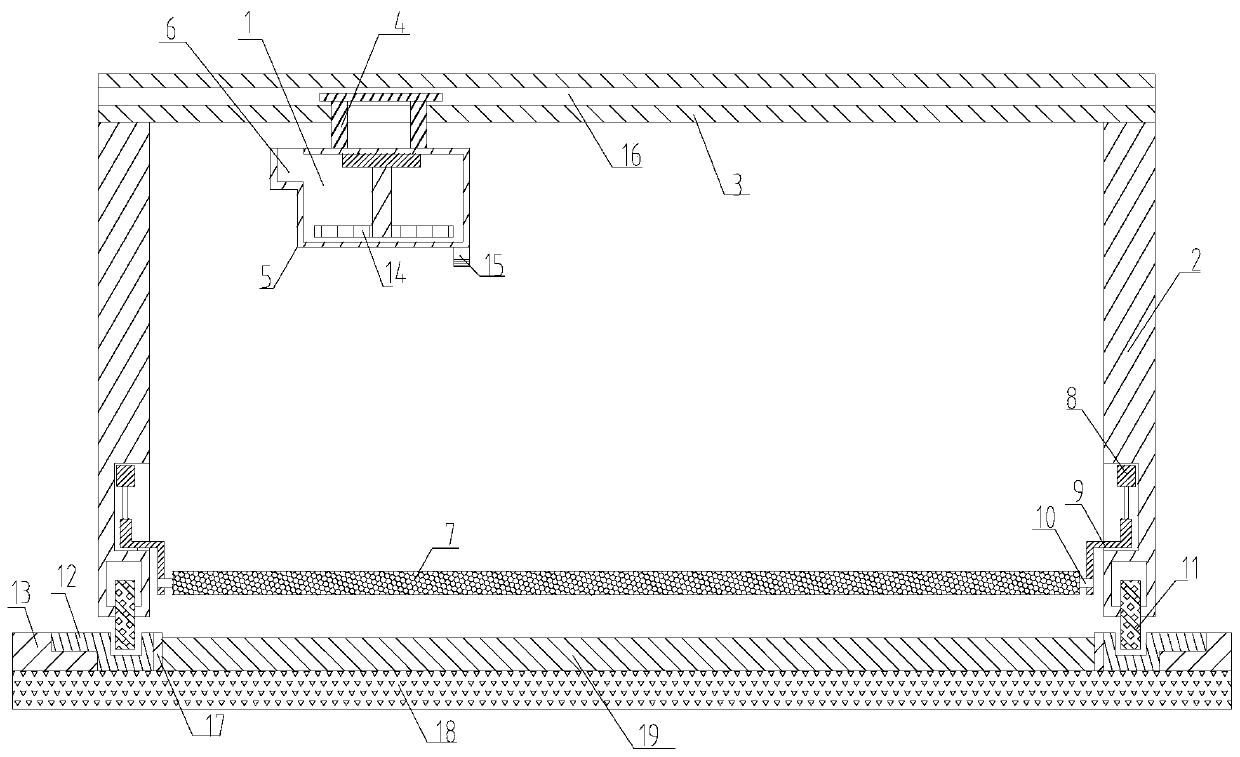

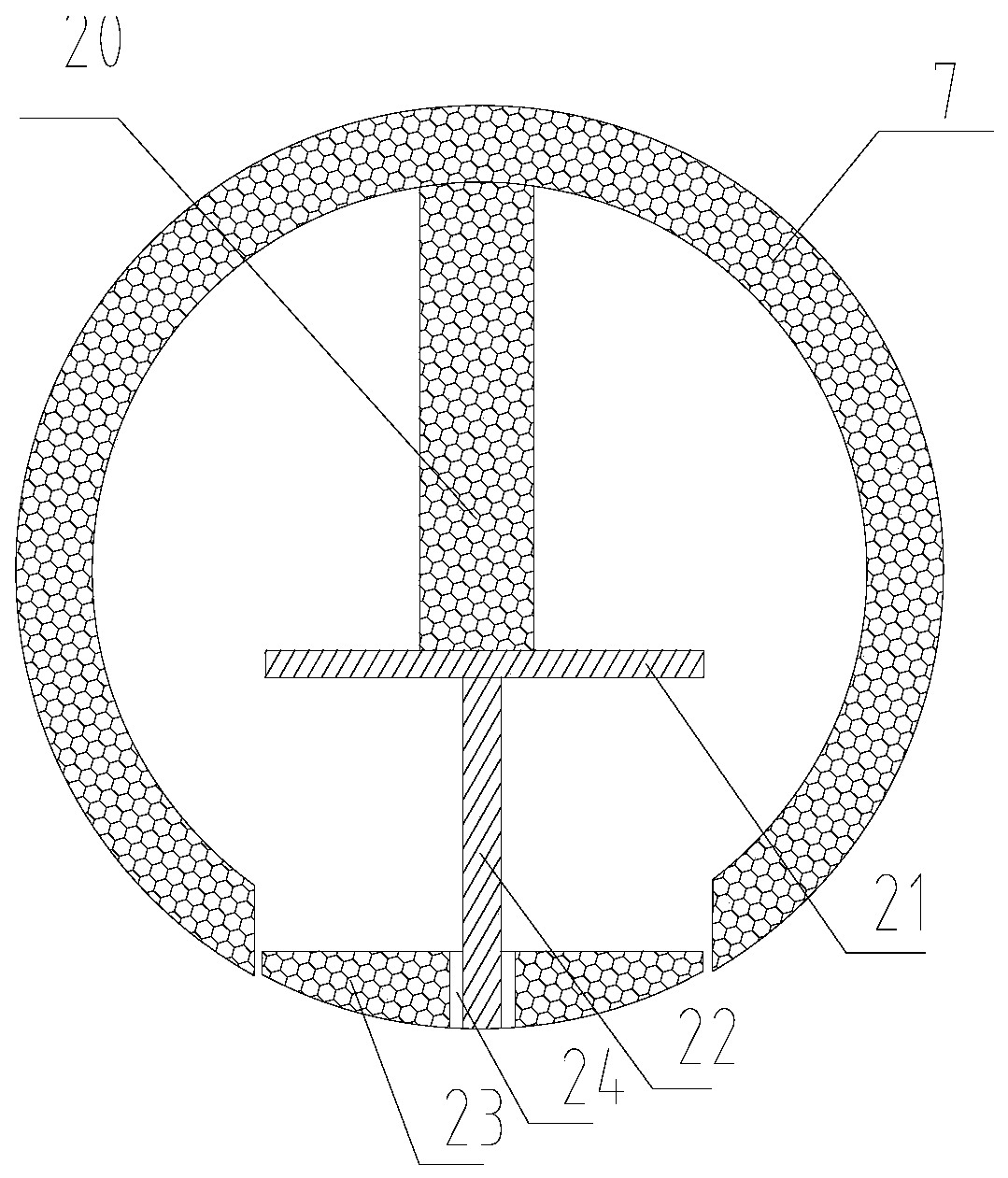

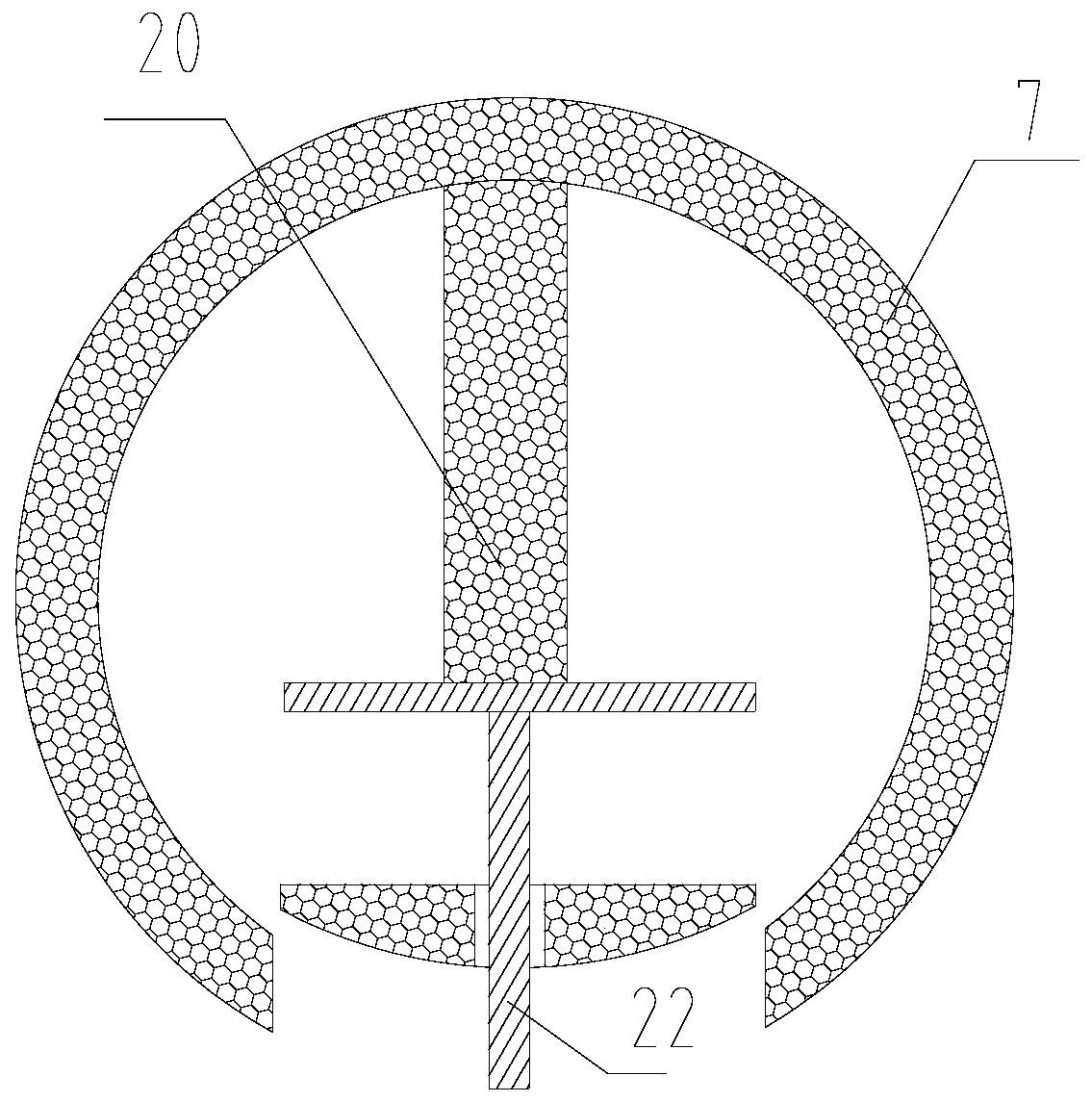

[0031] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

[0032] The present invention proposes a thin-layer wear-resistant ceramsite road surface construction method, comprising the following steps:

[0033] 1) Clean the base surface, use a broom to remove sundries and garbage on the road surface, and use a forest fire extinguisher to clean up road dust, mud and other impurities; the construction road surface is strictly prohibited from having obvious dust or mud, otherwise, tools such as forest fire extinguishers and brooms are required to further remove dust Treatment; if there are bumps on the construction road surface, they should be polished with a grinder on the bumps, and then cleaned after grinding; if there is water or moisture on the construction r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com