Brewing device for grape wine

A wine and sieve technology, applied in the preparation of wine, alcoholic beverages, biochemical equipment and methods, etc., can solve the problems of cumbersome operation process, deterioration of wine, insufficient extrusion of wine liquid, etc., to reduce pollution sources, Reasonable and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

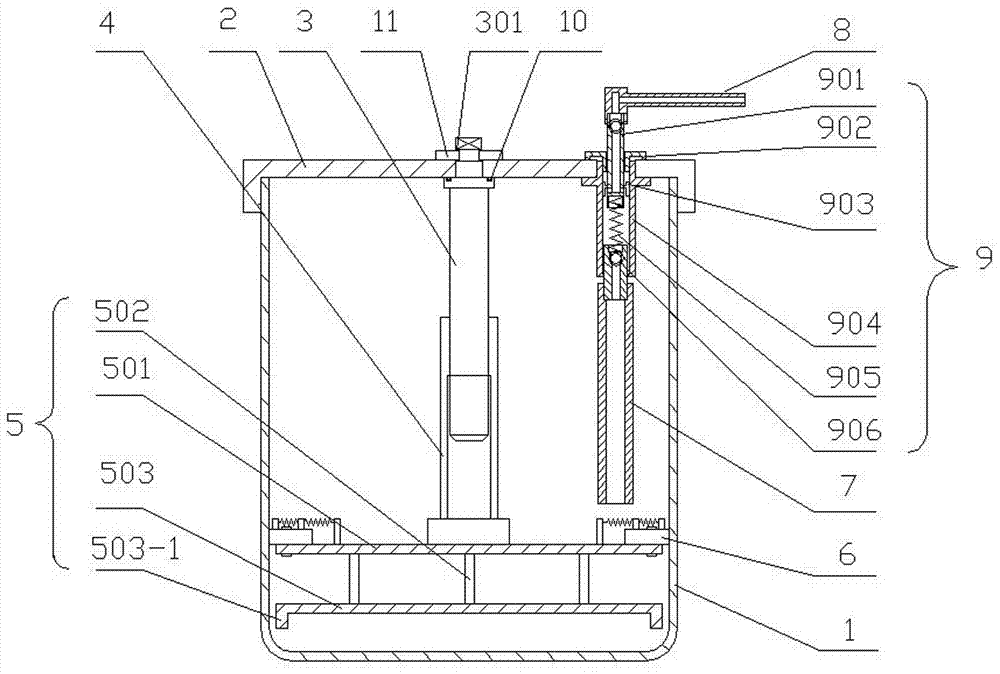

[0020] Such as figure 1 and figure 2 As shown, a wine brewing device of the present invention includes a cylindrical bottle body 1 and a bottle cap 2, the bottle body 1 is made of a dark glass material, and the bottle cap 2 is provided with a bottle for removing wine contained in grape skins. A squeeze mechanism for liquid extrusion and a liquid outlet mechanism for leading out the wine in the bottle body 1.

[0021] The extruding mechanism includes a lead screw 3 vertically pierced on the bottle cap 2, and a through hole is provided in the center of the bottle cap 2 for the lead screw 3 to pass through, and between the lower end surface of the bottle cap 2 and the lead screw 3 A sealing ring 10 is provided to maintain the airtight environment required for brewing in the bottle body 1 . The upper end of the leading screw 3 is set in a square shape, which is convenient to be twisted by a wrench or an installation handle. An annular groove 301 is arranged below the square up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com