Beer containing rich silkworm amino acids and production process

A technology for silkworm chrysalis amino acid and beer, which is applied to the field of beer rich in silkworm chrysalis amino acid and production technology, can solve problems such as overhead, headache, hangover, etc., and achieves the effects of promoting metabolism speed, convenient operation, and not easy to hangover.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 takes cooked beer as the production of the silkworm chrysalis amino acid beer of base wine

[0035] The production process of cooked beer is:

[0036] (1) Add rice or cornstarch or cornstarch syrup to the gelatinization pot at 50°C and keep warm for 15 minutes, raise the temperature to 92°C, and keep warm for 15 minutes;

[0037] (2) Add malt powder to the saccharification pot at 48°C and keep warm for 30 minutes;

[0038] (3) Put the material in the gelatinization pot into the mash pot and mash, and the temperature after mashing is 60-70°C;

[0039] (4) filter;

[0040] (5) Boil for 70-90min, add 0.05% hops;

[0041] (6) cooling the wort to 9°C;

[0042] (7) ferment for about 15 days;

[0043] (8) filter;

[0044] (9) The liquor stays in the sake tank for 16 hours; during this period, 0.15% (w / v, unit is g / 100mL) silkworm chrysalis amino acid is added through the pump.

[0045] (10) Sterilization and packaging.

[0046] The beer without silkworm ch...

Embodiment 2

[0049] Embodiment 2 takes wheat beer as the production of the silkworm chrysalis amino acid beer of base wine

[0050] During the production of wheat beer, 0.175% (w / v, g / 100mL) of silkworm chrysalis amino acids are added through a pump in the beer sake tank, and after conventional packaging, silkworm chrysalis amino acid wheat beer is obtained.

[0051] The production process of wheat beer:

[0052] (1) Add rice or cornstarch or cornstarch syrup to the gelatinization pot at 50°C and keep warm for 15 minutes, raise the temperature to 92°C, and keep warm for 15 minutes;

[0053] (2) Add malt powder and wheat malt powder (wheat malt powder accounts for 40%) to the saccharification pot at 48°C, and keep warm for 30 minutes;

[0054] (3) Put the material in the gelatinization pot into the mash pot and mash, and the temperature after mashing is 60-70°C;

[0055] (4) filter;

[0056] (5) Boil for 70-90min, add 0.05% hops;

[0057] (6) cooling the wort to 9°C;

[0058] (7) ferme...

Embodiment 3

[0062] Embodiment 3 is the production process of silkworm chrysalis amino acid beer with pure draft beer as base wine

[0063]In the pure draft beer production process, 0.20% (w / v, g / 100mL) silkworm chrysalis amino acids are added through a pump in the beer sake tank, and silkworm chrysalis amino acids pure draft beer is obtained after conventional packaging. The quality index of the produced silkworm chrysalis amino acid beer meets the requirements of Table 4 and Table 5.

[0064] Table 4 Sensory evaluation results of silkworm chrysalis amino acid pure draft beer

[0065]

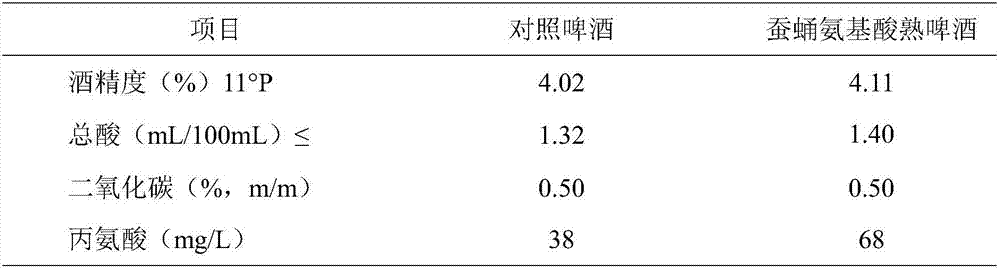

[0066] Table 5 Physicochemical indicators of silkworm chrysalis amino acid pure draft beer

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com