Method for increasing flavor promoting ageing of soybean-flavor white spirits

A technology of liquor and soy sauce, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of soy-flavored liquor with heavy taste, lack of outstanding grain aroma, and insufficient comfort, so as to reduce the spicy feeling, highlight the grain aroma, and reduce the pungency Sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

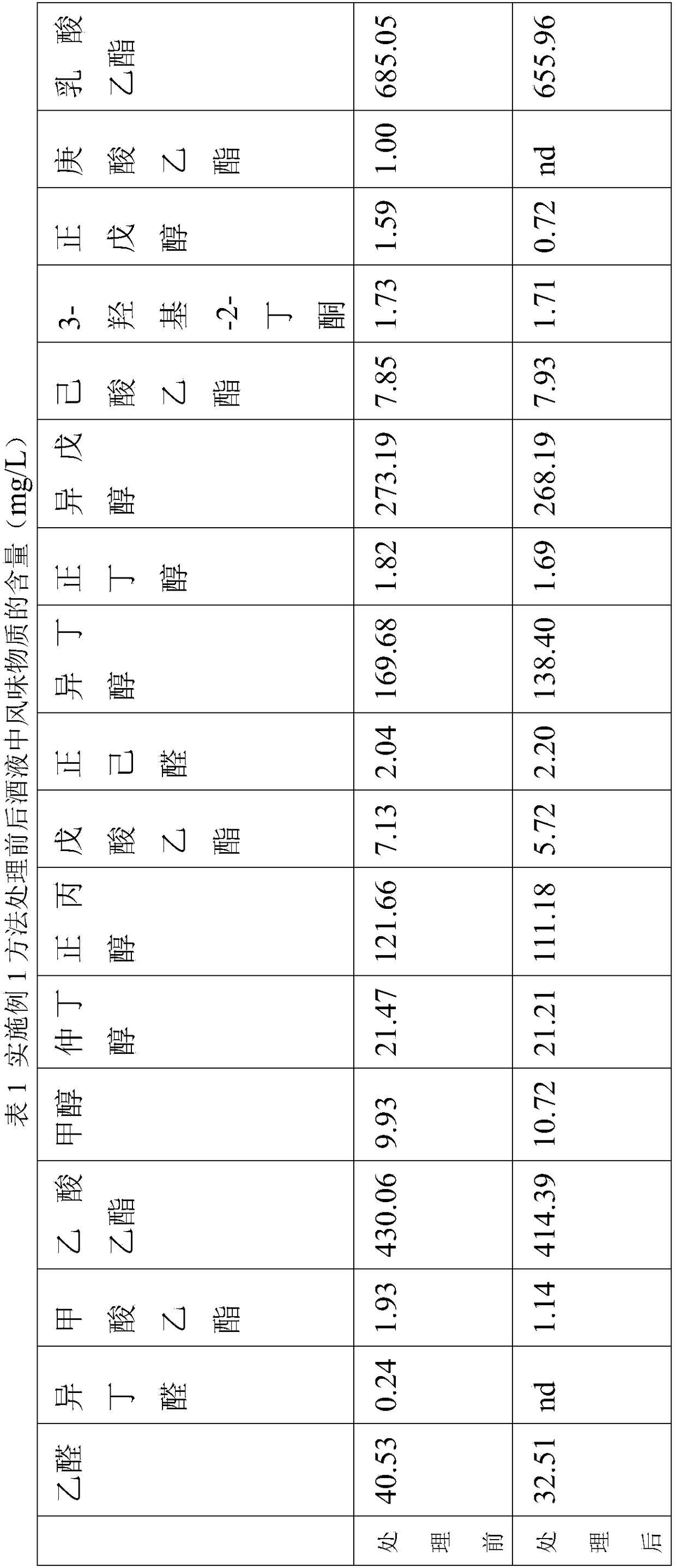

Embodiment 1

[0026] A production method for improving the flavor of soy-flavored liquor and promoting its maturation, comprising the following steps:

[0027] Seal 100 tons of 30-degree soy-flavored liquor in a stainless steel tank with heat-insulating material on the outer layer, add 30 kilograms of 18 angstrom activated carbon powder, and feed clean compressed air for 20 minutes at the same time; The temperature of the solution was lowered to 4°C and maintained for 12h.

[0028] The temperature was lowered to 1°C by the refrigerating unit again, and at the same time, clean compressed air was introduced for 20 minutes, and the maintenance time was 24 hours.

[0029] Pass clean compressed air again for 20 minutes, and continue to maintain the temperature at 1°C for 36h.

[0030] Use a diatomaceous earth filter to filter the wine at 1°C until it becomes clear and translucent, then pass clean compressed air for 20 minutes, and return the wine to normal temperature to obtain the processed wi...

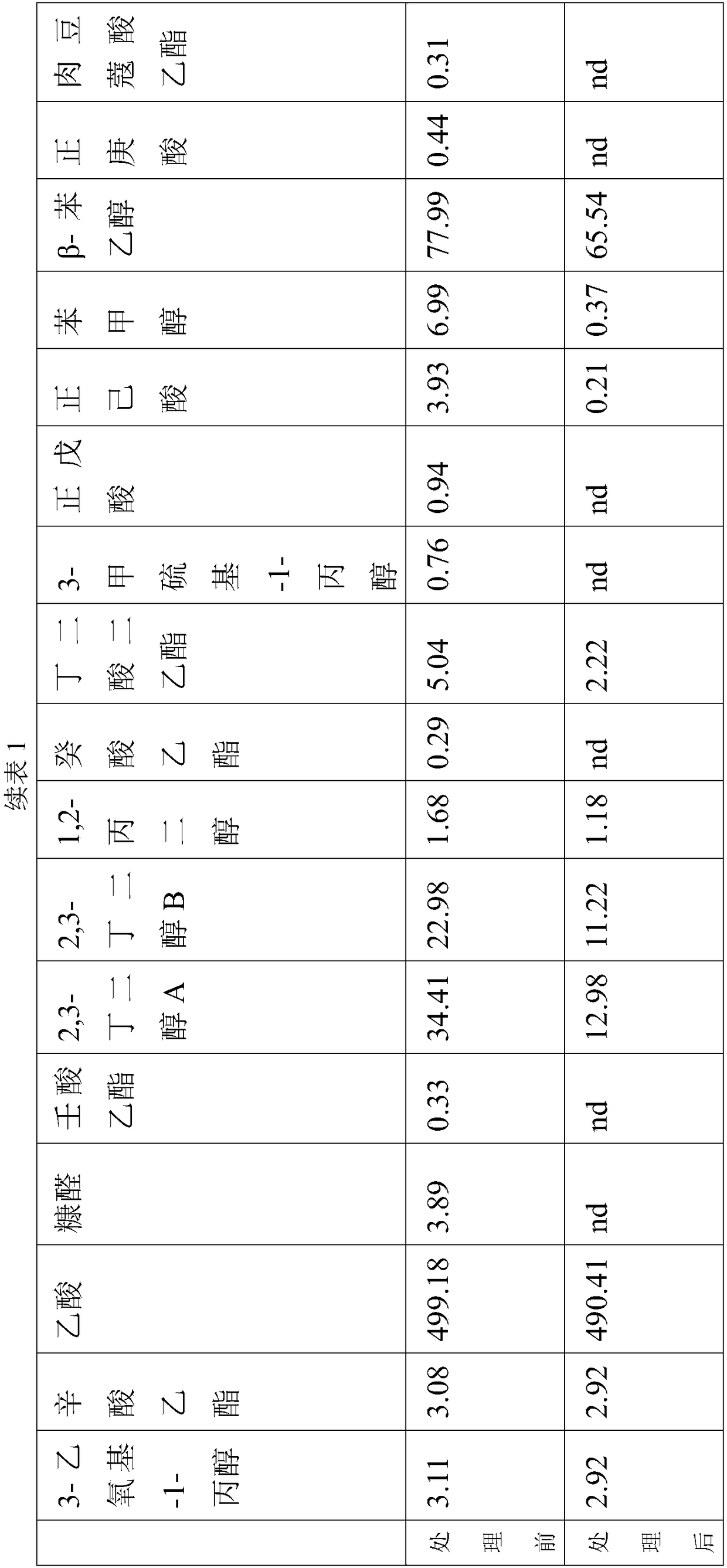

Embodiment 2

[0032] A production method for improving the flavor of soy-flavored liquor and promoting its maturation, comprising the following steps:

[0033] Seal 100 tons of 35-degree soy-flavored liquor in a stainless steel tank with heat-insulating material on the outer layer, add 60 kilograms of 20 angstrom activated carbon powder, and feed clean compressed air for 30 minutes at the same time; The temperature of the solution was lowered to 6°C and maintained for 12h.

[0034] The temperature was lowered to -5°C by the refrigerating unit again, and at the same time, clean compressed air was introduced for 30 minutes, and the maintenance time was 36 hours.

[0035] Pass clean compressed air again for 30 minutes, and continue to maintain at -5°C for 12 hours.

[0036] After filtering the liquor at -5°C until clear and translucent with a diatomaceous earth filter, pass through clean compressed air for 30 minutes, and return the liquor to normal temperature to obtain the treated liquor. ...

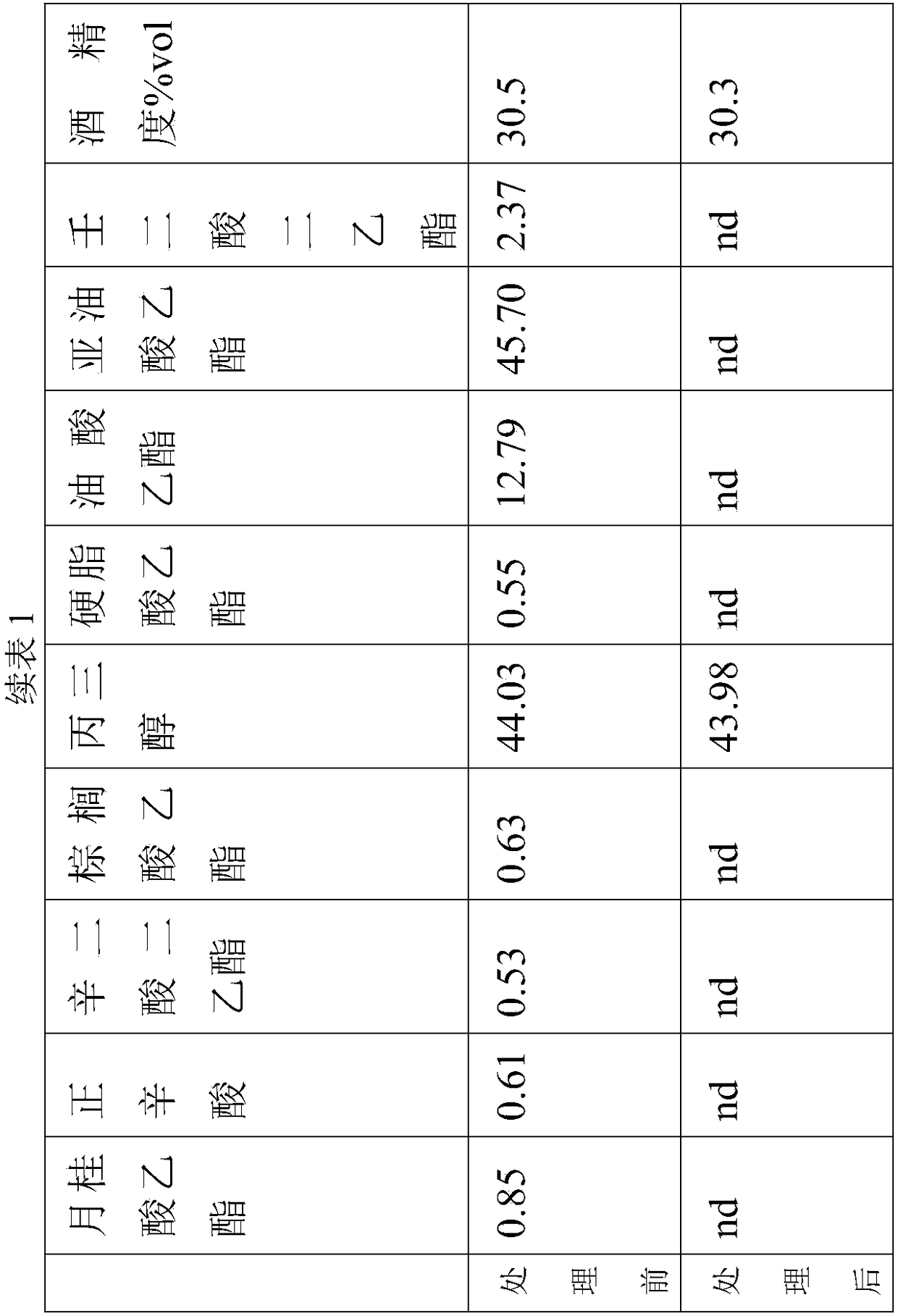

Embodiment 3

[0038] A production method for improving the flavor of soy-flavored liquor and promoting its maturation, comprising the following steps:

[0039] Seal 100 tons of 28-degree soy-flavored liquor in a stainless steel tank with heat-insulating material on the outer layer, add 10 kg of 16 angstrom activated carbon powder, and feed clean compressed air for 15 minutes at the same time; The temperature of the solution was lowered to 1°C and maintained for 12h.

[0040] The temperature was lowered to 0°C by the refrigerating unit again, and at the same time, clean compressed air was introduced for 30 minutes, and the maintenance time was 12 hours.

[0041] Pass clean compressed air again for 15 minutes, and continue to maintain the temperature at 0°C for 72 hours.

[0042] Use a diatomaceous earth filter to filter the wine at 0°C until it becomes clear and translucent, then pass clean compressed air for 15 minutes, and return the wine to normal temperature to obtain the processed wine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com