Fixed-length steel strand blanking machine and steel strand machining method

A steel strand and feeder technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that steel strands are easy to deviate from the track, the degree of automation is not high, and the labor cost is high, so as to achieve convenient and stable operation, compression The effect of occupying space and reducing equipment error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

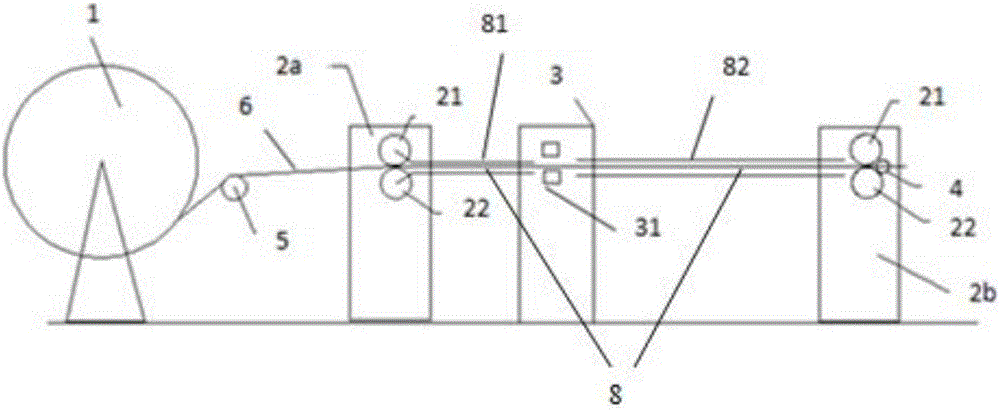

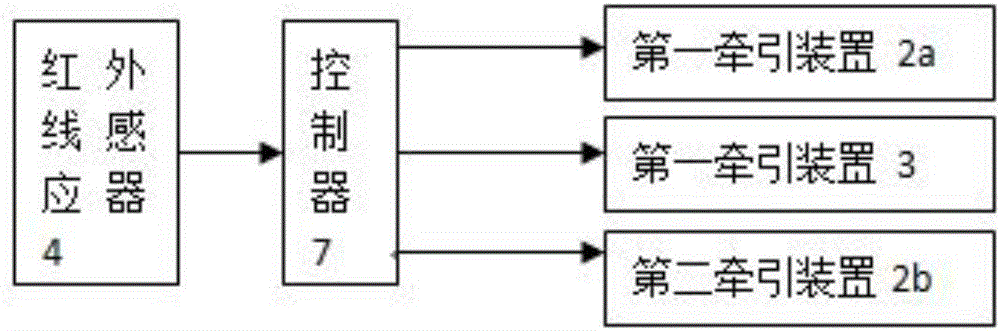

[0022] see figure 1 , which is a schematic structural diagram of the fixed-length steel strand blanking machine described in this embodiment, the blanking machine includes a steel strand reel 1 and a cutting machine 3 for cutting the steel strand 6, and the steel strand A first traction device 2a is provided between the wire reel 1 and the cutting machine 3, and a second traction device 2b is also provided at the rear of the cutting machine 3, and conduits 8 are provided on both sides of the cutting machine 3, and the second traction device 2b is provided at the rear of the cutting machine 3. The traction device 2b is located on the side of the construction station. Wherein the first traction device 2a is used to transport the steel strand 6 on the steel strand reel 1 to the cutting machine 3, and the second traction device 2b is used to extract the steel strand 6 cut by the cutting machine 3 Cutting machine 3 and transported to the construction station.

[0023] Specificall...

Embodiment 2

[0030] This embodiment provides a processing method using the fixed-length steel strand cutting machine described in Embodiment 1, comprising the following steps: S1, artificially measure a steel strand of a target length according to the required length of the steel strand 6 line as a reference sample, and choose a pipeline consistent with the length of the reference sample as the second conduit 82 between the cutting machine 3 and the second pulling device 2b;

[0031] S2, adjusting the position of the driven wheel 21 of the first traction device 2a and the second traction device 2b so as to facilitate the installation of the steel strand 6;

[0032] S3, the reference sample product is inserted into the second conduit 82 from between the driven wheel 21 and the driving wheel 22 of the second traction device 2b, and the front end of the reference sample is engaged by adjusting the driven wheel 21 to engage the front end of the reference sample Between the driving wheel 22 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com