Water filtration and purification system for mill dust

A purification system and water filtration technology, applied in chemical instruments and methods, using liquid separation agent, separation of dispersed particles, etc., can solve the problems of passing through filter holes, secondary pollution, dust inhalation into workers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

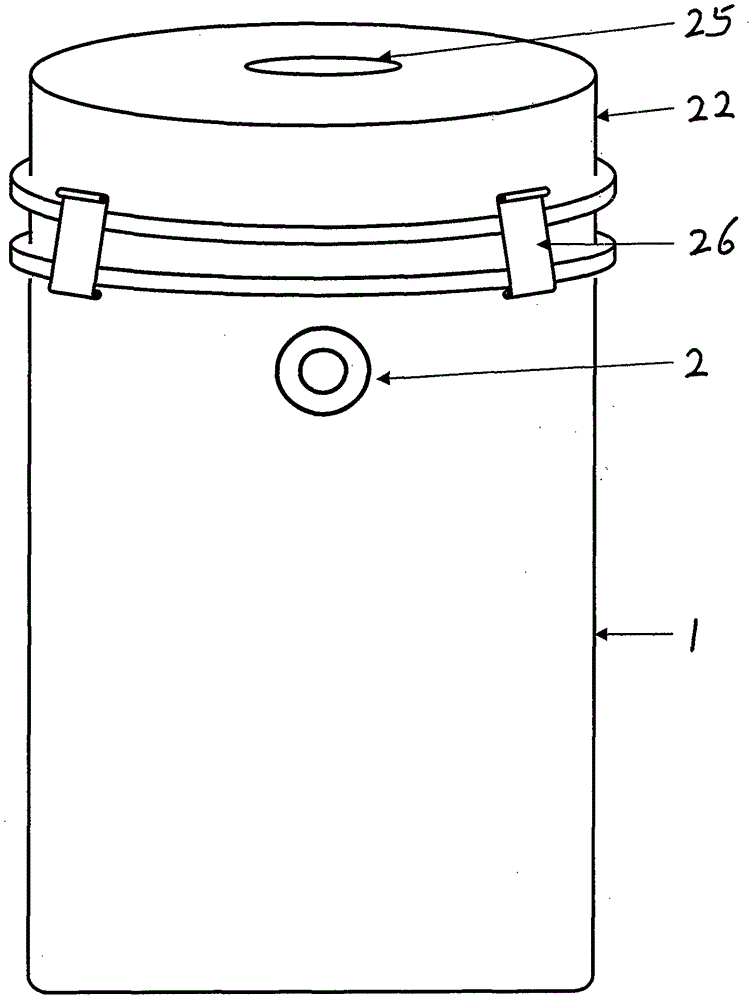

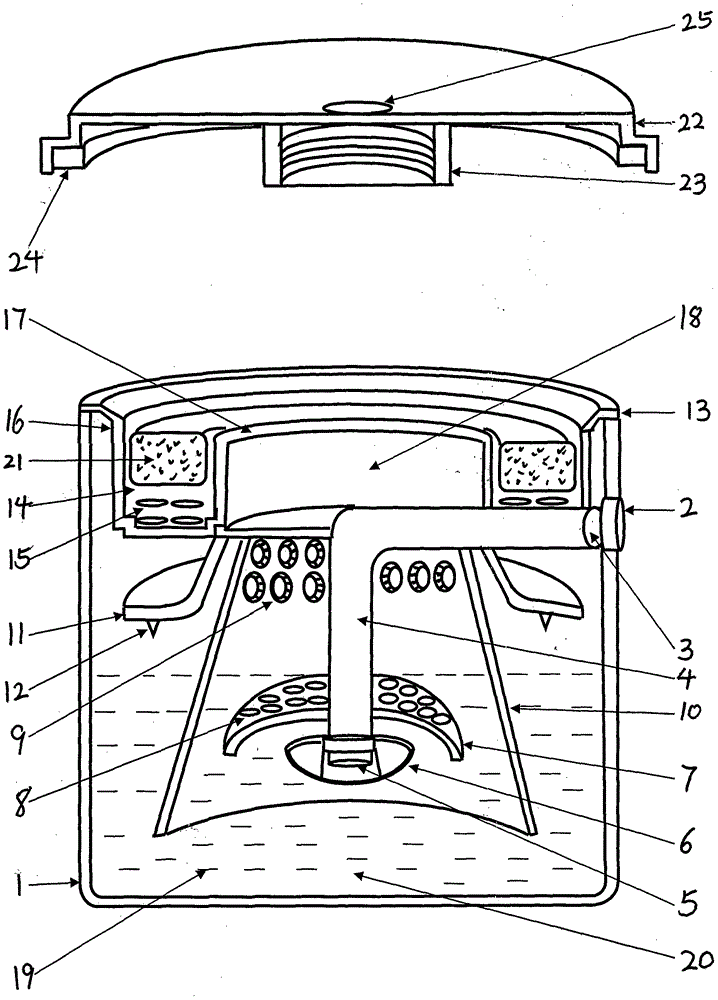

[0008] A dusty water filtration and purification system is composed of an upper cover part, water filtration and purification system components, a dust collection barrel, and a dust collection area.

[0009] Such as figure 1 , figure 2 As shown, the upper part of the side wall of the dust collection bucket 1 is provided with an external dust inlet hole 2, except for the dust inlet hole 2, the side wall and bottom of the dust collection bucket 1 are closed, and the upper part is open. The upper cover part is mainly composed of an upper cover 22, an upper filter layer 23, a sealing gasket 24, and an upper air outlet 25. The side wall of the upper cover 22 is sealed. There is an upper air outlet 25 at the center of the top end. The upper filter layer 23 is located inside the upper cover 22. At the center position, the gasket 24 is located at the lower part of the upper cover 22. Together with the buckle 26, it mainly plays a role in sealing the connection between the upper cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com