Labor protection glove

A technology for labor protection gloves and gloves, applied in gloves, clothing, clothing, etc., can solve the problems of waste of resources, entanglement, and death, and achieve the effect of reducing whitening or blistering, reducing processing costs, and small development investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

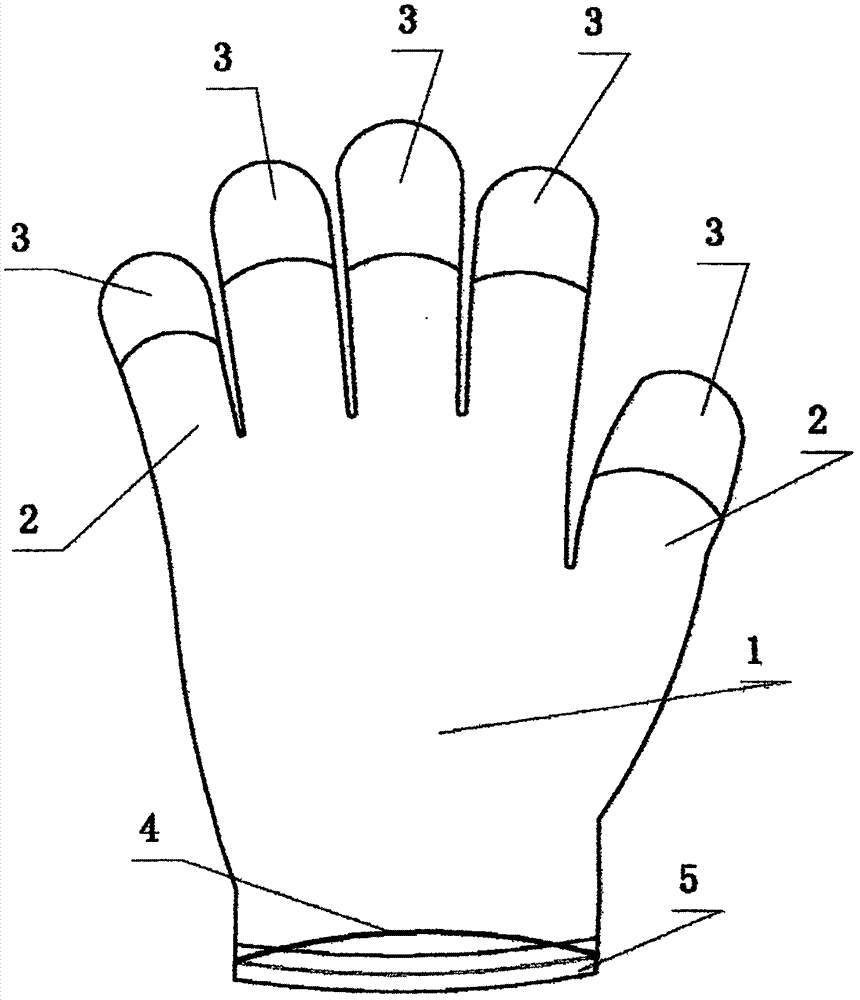

[0011] like figure 1 As shown: the upper end of the palm surface of the hand guard (1) is connected to the belly of the finger guard (2), the front end of the belly of the finger guard (2) has a finger cavity (3), and the necking belt (4) is located at the lower part of the palm The neck band can be made of rubber band or other elastic soft fabric, and the neck band is woven into the lower part of the glove body or the lower part of the glove body is passed through the ring of the neck band and then crimped (prefabricated one side of the neck band in the over-shrink In the mouth band channel (5), the neck band and the palm surface of the hand guard form a hand channel.

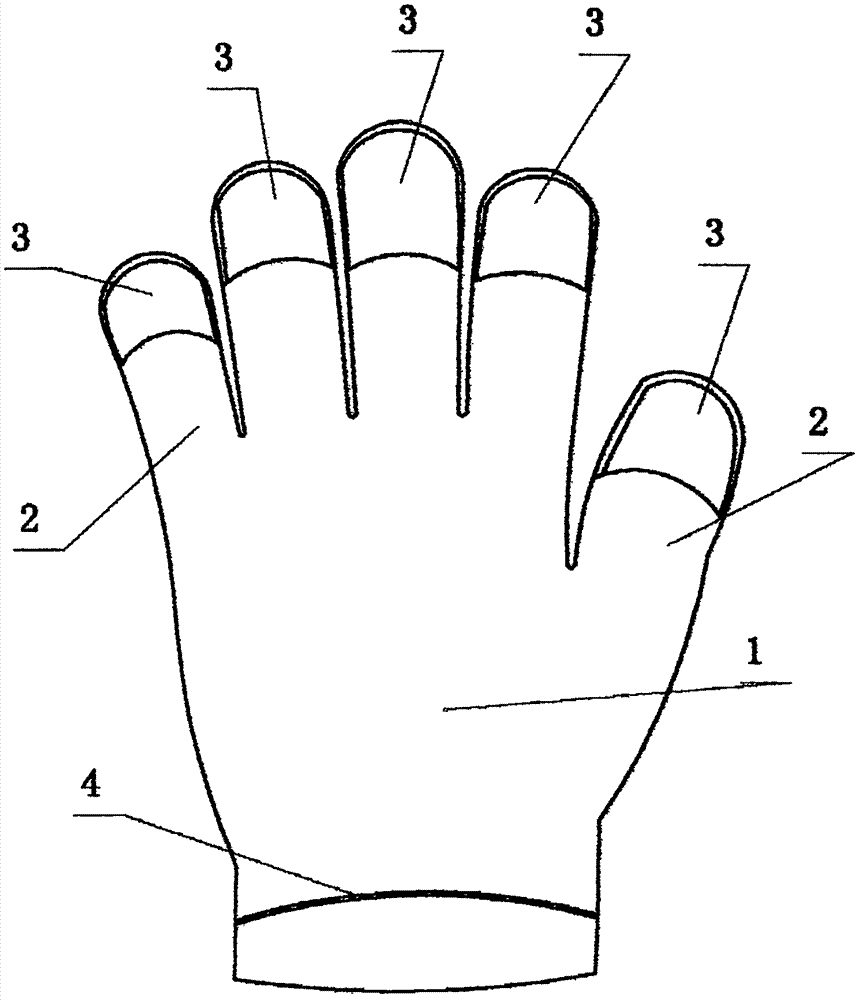

[0012] like figure 2 As shown: the upper end of the palm of the hand guard (1) is connected to the belly of the finger guard (2), the front end of the belly of the finger guard has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com