Stator mounting apparatus, stator mounting structure and fan system

A technology of installation device and installation structure, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve problems such as large vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the present invention, in the case of no contrary description, the used orientation words such as "up, down, left and right" usually refer to the up, down, left and right shown in the accompanying drawings; "inside and outside" Refers to the inside and outside of the outline of each part itself.

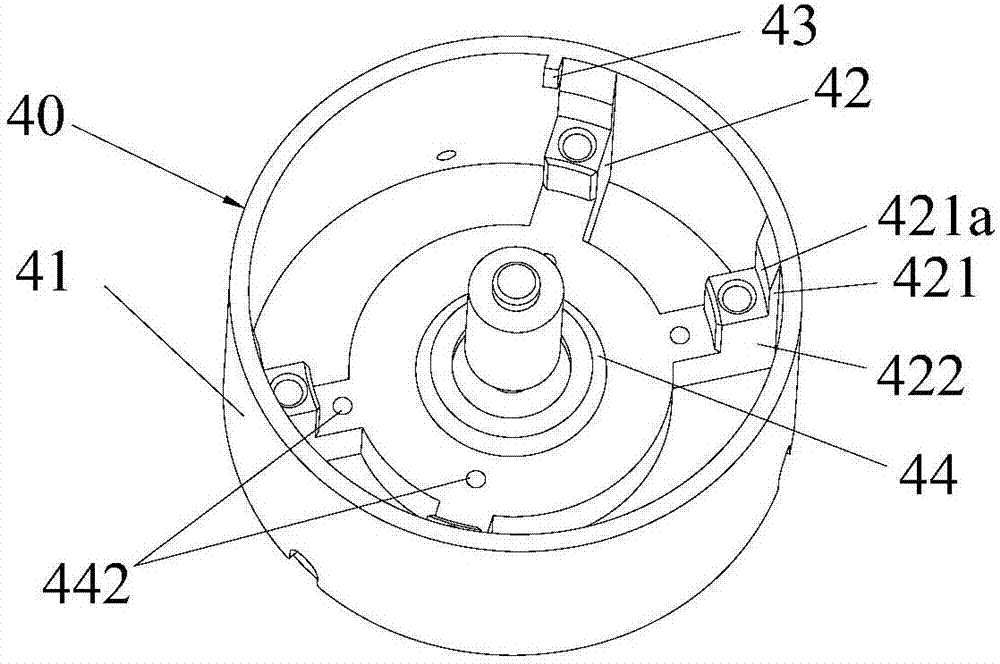

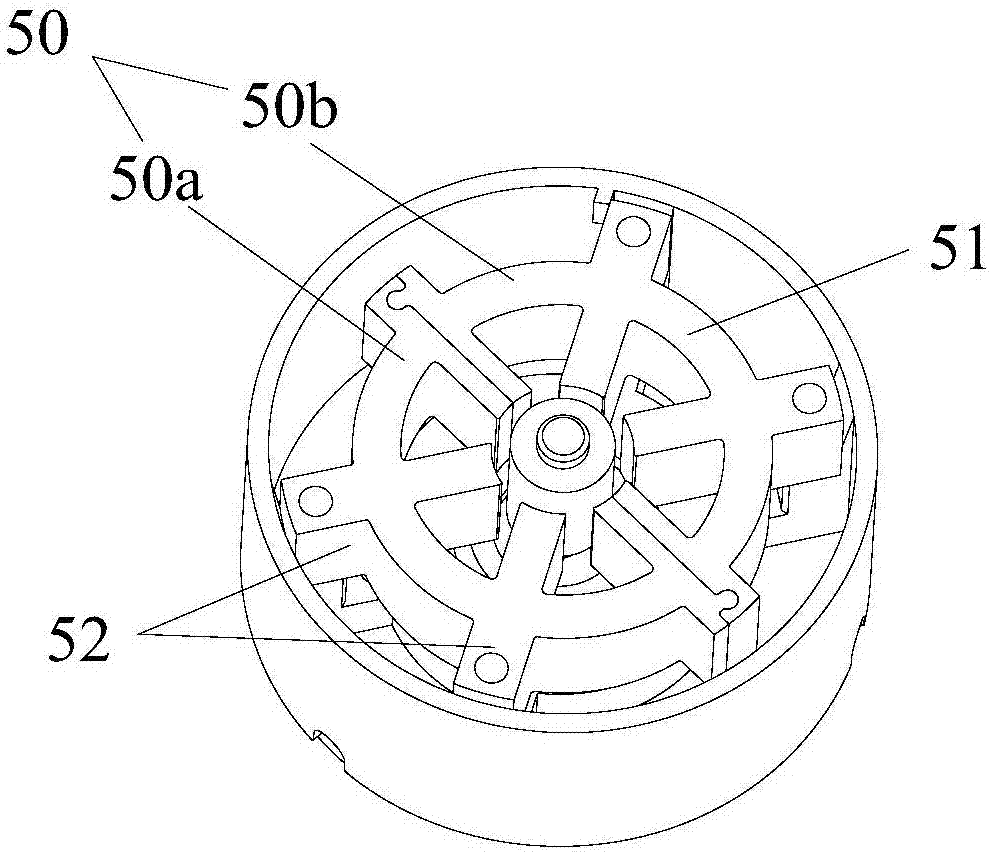

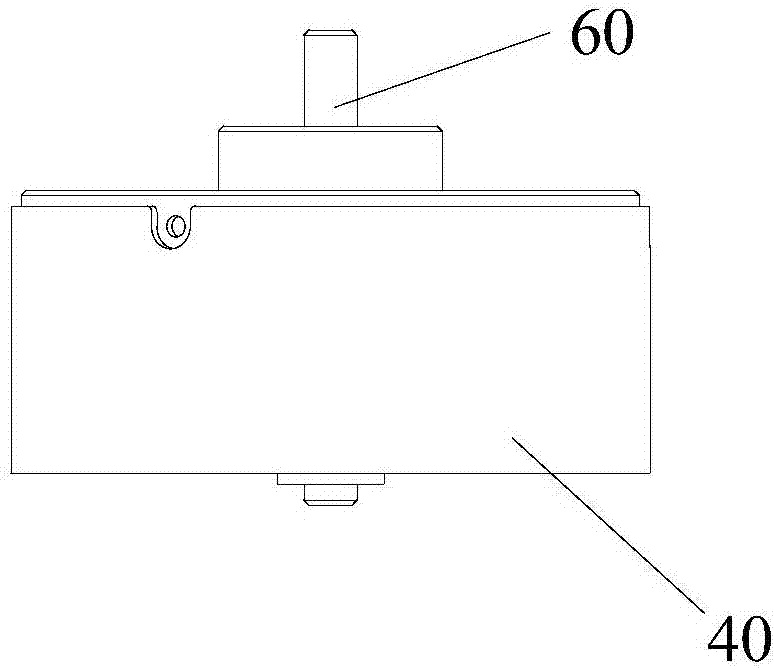

[0027] According to one aspect of the present invention, a stator installation device is provided, wherein the stator installation device 40 includes a cylindrical casing 41 and a connecting piece 42 installed on the inner wall of the casing 41, and the connecting piece 42 includes The first part 421 connected to the housing 41 and the second part 422 extending from the first part 421 toward the inside of the housing 41, the stator 50 is mounted on the second part 422, and the first part 421 is set There is a radial positioning portion 421 a for radially limiting the installation position of the stator 50 , and a circumferential positioning portion 43 for circumferentially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com