Jack-free socket and tooth-free connector matched with same

A socket and shell technology, applied in the field of toothless joints, can solve problems such as increased power consumption, tripping of the air switch of the main power supply, loss of elasticity of metal sheets, etc., and achieves easy manufacturing, installation and use, improved safety and reliability of use, and overall structure cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

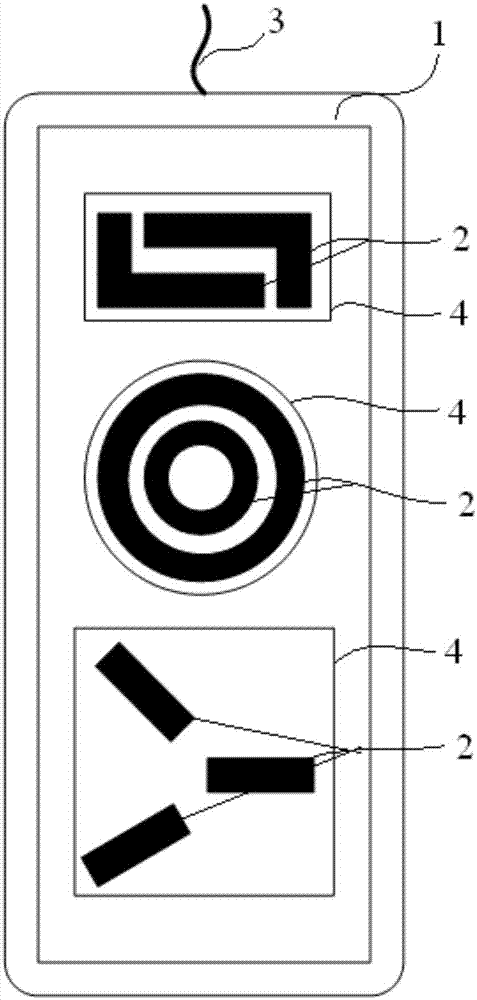

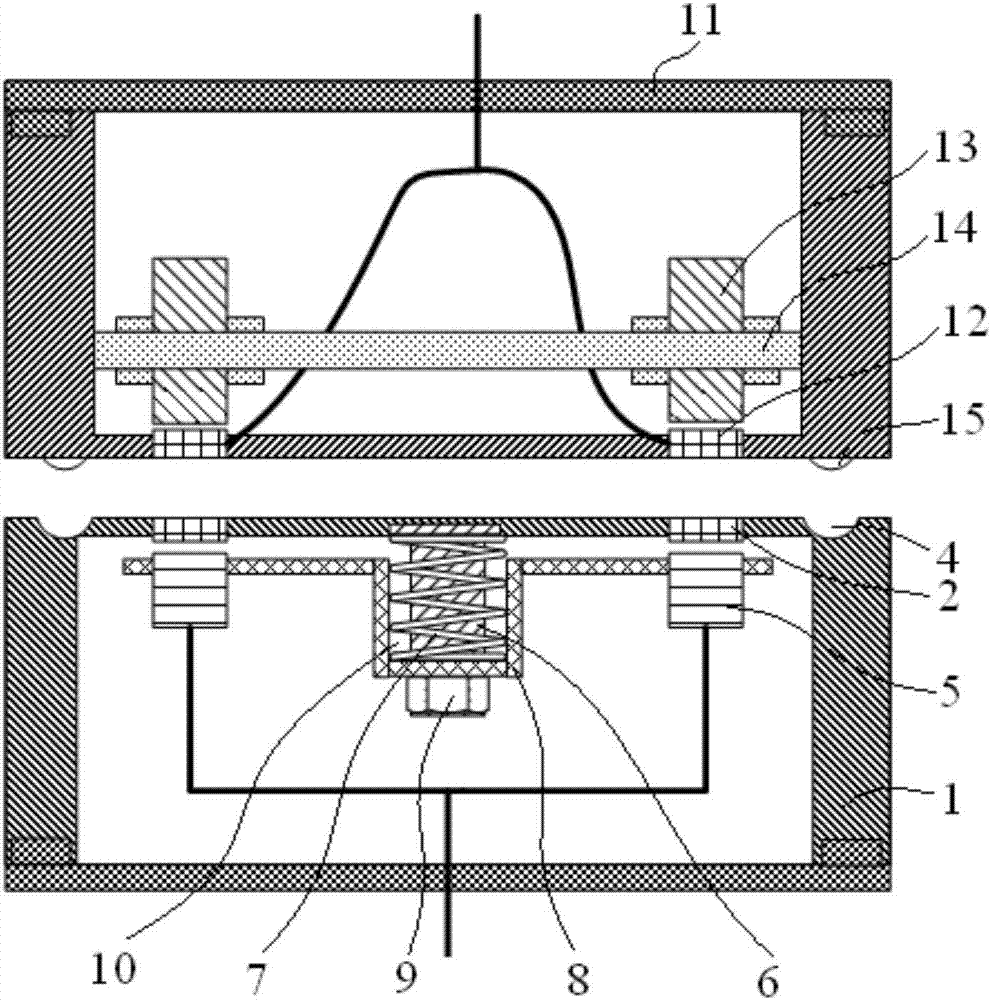

[0030]Embodiment 1: as figure 1 and 2 As shown, a non-porous socket includes a socket housing 1 with an inner cavity and a first conductive metal sheet 2, an iron core 5, a wire 3, and an elastic reset mechanism arranged on the socket housing 1. The first The conductive metal sheet 2 is clamped on the surface of the socket housing 1, and the upper surface of the first conductive metal sheet 2 is exposed on the surface of the socket housing 1, and the elastic reset mechanism is fixedly arranged in the inner cavity of the socket housing 1, The iron core 5 is fixedly arranged on the elastic reset mechanism, and the iron core 5 is welded to the wire 3, and the wire 3 is drawn out from the inner cavity of the socket housing 1. Between the first conductive metal sheet 2 and the iron core 5 Under the action of elastic compression of the elastic reset mechanism, contact and electrical connection can be realized. In addition, the bottom of the socket housing 1 is configured as a deta...

Embodiment 2

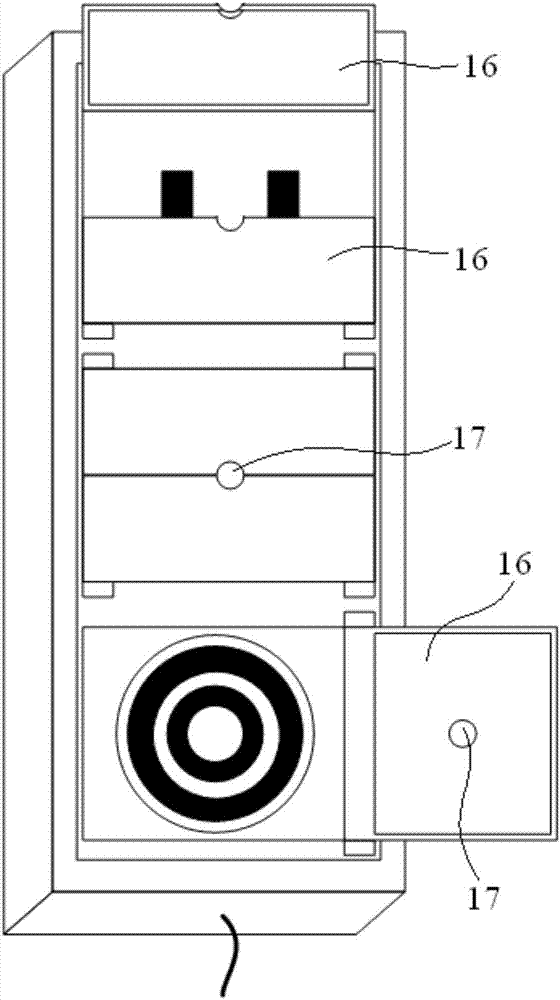

[0041] Embodiment 2: as Figure 4-8 As shown, as an improvement to the non-porous socket described in Embodiment 1, this embodiment discloses a countersunk non-porous socket, which includes a socket housing 1 with an inner cavity and a socket housing 1 The movable panel 18, the first conductive metal sheet 2, the iron core 5, the wire, the elastic reset mechanism, the socket housing 1 is provided with a groove 19 for installing the movable panel 18, and the elastic reset mechanism is arranged in the groove 19, and the elastic reset mechanism is located at the bottom of the movable panel 18, the movable panel 18 is in contact with the elastic reset mechanism, and the movable panel 18 can move up and down in the groove 19 under the elastic compression of the elastic reset mechanism. The first conductive metal sheet 2 is fixedly clamped on the movable panel 18, and the upper surface of the first conductive metal sheet 2 is exposed on the surface of the movable panel 18 to replace...

Embodiment 3

[0052] Embodiment 3: as Figure 9 and 10 As shown, as an improvement to the toothless joint disclosed in Embodiment 1 or 2, the toothless joint also includes a guide column frame 31, an iron core 32, a wire gathering metal ring 33, a compression spring 34, and a support member 35 , the inner copper sheet 36, the guide column frame 31 is fixedly installed inside the joint housing, the wire gathering metal ring 33 is arranged in the middle of the guide post frame 31, and the wire gathering metal ring 33 is preferably made of copper with good electrical conductivity ring. The guide post frame 31 is provided with a plurality of intersecting guide posts, the ends of the guide posts are sleeved with a support member 35 and a compression spring 34, and the middle part and both ends of the support member 35 are provided with draw-in slots, and the support member 35 has a limiting effect on the compression spring 34 in the middle of the slot. The iron core 32 is arranged on the slots...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com