Surface paster processing technology

A processing technology and surface sticking technology, applied in electrical components, electrical switches, circuits, etc., can solve problems such as increased cost, fading, deformation, shortened service life, etc., to achieve the effect of reducing cost and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

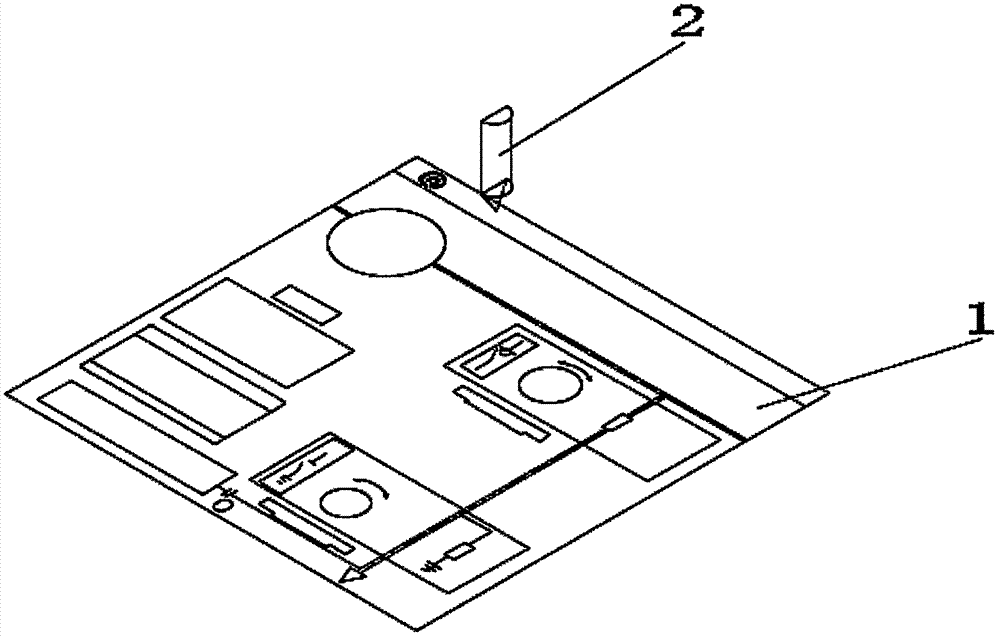

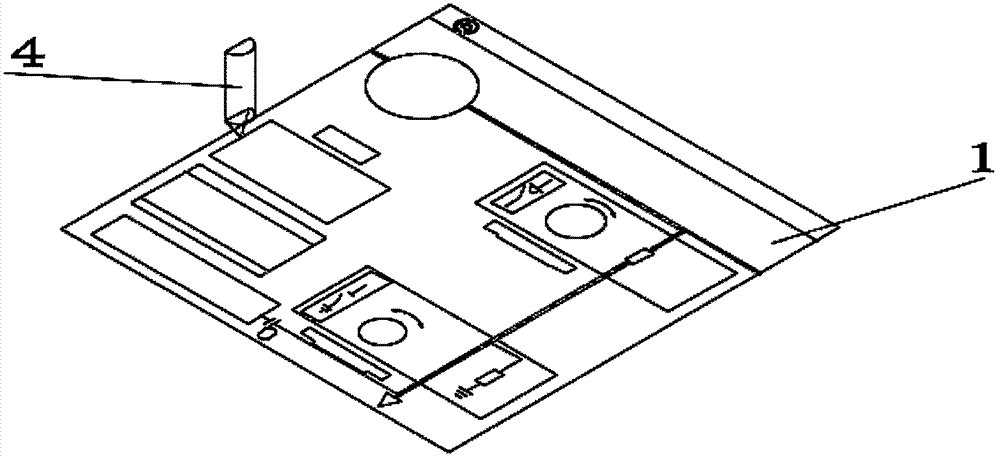

[0041] see Figure 1 to Figure 3 , the present invention provides a technical solution: surface paste processing technology, including step S1, using the engraving machine software to edit the program; step S2, planning the engraving path 1; step S3, sequentially performing two-dimensional engraving, two-dimensional drawing, two-dimensional Cutting three engraving techniques, two-dimensional engraving, two-dimensional drawing and two-dimensional cutting use different tool diameters, the knife has a 0.4MM sharp knife 3, a 1MM sharp knife 2 and a 2MM sharp knife 4; step S4 is carried out on the engraving path after the above step S3 1 for the integrated proofreading of surface sticker materials.

[0042] The 1MM sharp knife 2 is a two-dimensional drawing processing technology. The purpose of processing it is to accurately engrave the font symbols on the PU two-color plate. At the same time, it can control the size of the knife according to the program and accurately control the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com