Multifunctional heat pump drying device

A technology of heat pump drying and heat pump, which is applied in the direction of heating device, drying gas arrangement, heat pump, etc., can solve the problems that it is difficult to meet the drying process and quality index requirements of different materials, and cannot well adapt to the diversity of drying objects in outdoor environmental conditions, etc. Achieve the effects of improving dehumidification capacity, controllable relative humidity, and efficient waste heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

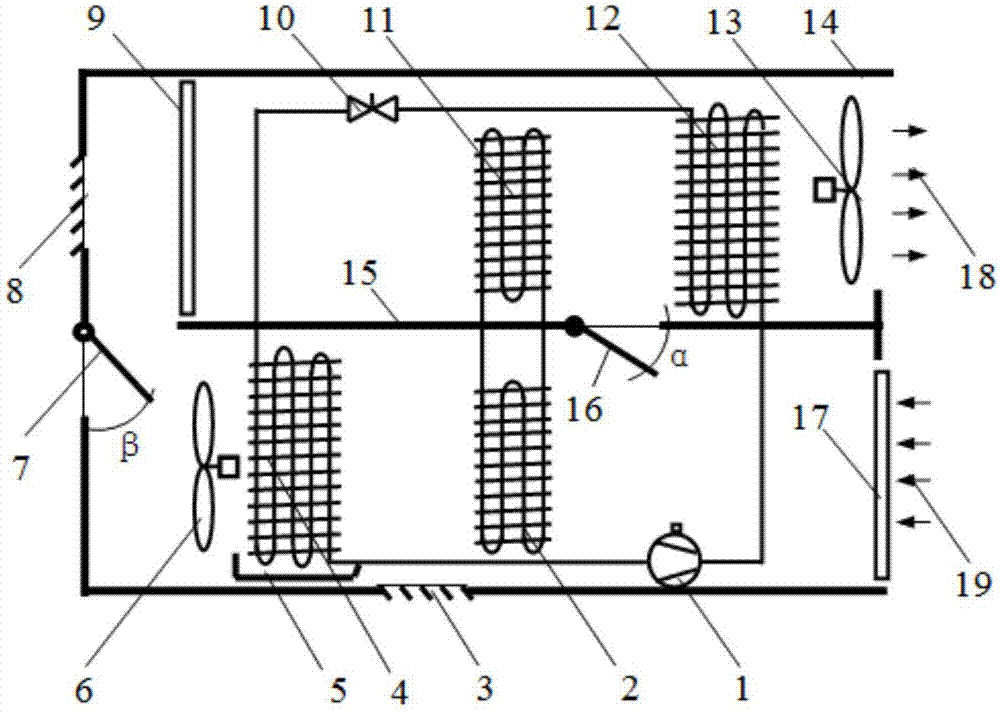

[0045] see figure 1In this embodiment, the multi-operation mode heat pump drying device is an integral structure in which the heat pump circulation system and the drying medium heat and humidity treatment channel are jointly arranged in the casing 14, and the inner cavity of the casing 14 is divided into a lower passage by a horizontal partition 15 and the upper channel, the air return port 19 is the entrance of the lower channel, and the air supply port 18 is the outlet of the upper channel, and the air return port 19 and the air supply port 18 are located at the right end of the casing 14; the lower channel and the upper channel are connected up and down at the left end of the casing 14 ; The first air filter 17, the compressor 1, the heat pipe evaporation end 2, the evaporator 4 and the evaporation fan 6 are located in the lower passage, and the return air obtains waste heat recovery and cooling and dehumidification in the lower passage; the second air filter 9, the expansio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com