Working method of high-voltage distribution room

A technology of high-voltage power distribution and working methods, applied in substation/power distribution device casing, heating method, electrical components, etc., can solve problems such as short circuit of switchgear, high switch temperature trip, damage to indoor facilities, etc., to reduce use time, Save air-conditioning costs and ensure high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

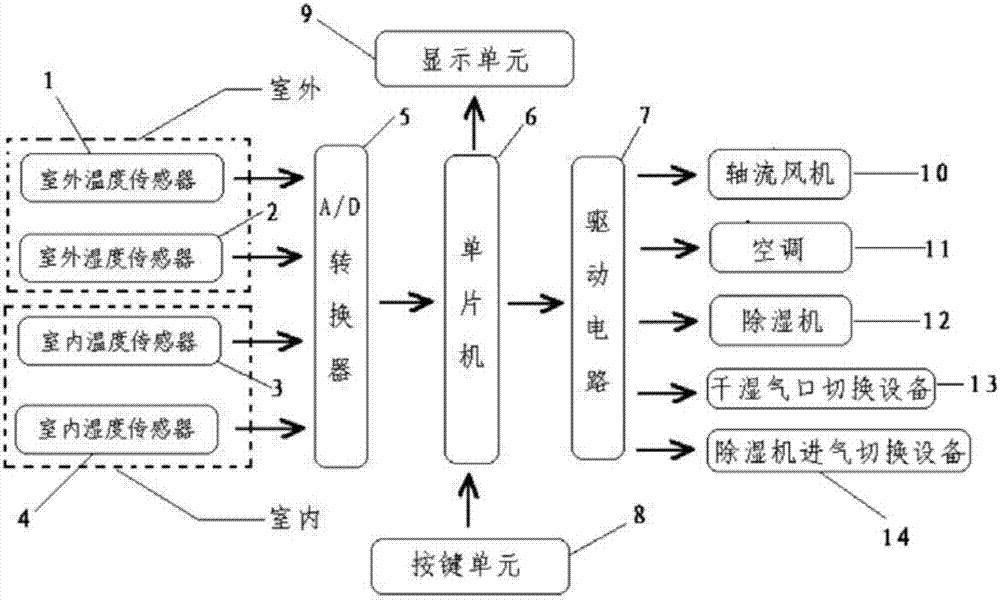

[0049] As shown in the accompanying drawings, a cooling and dehumidification method for a high-voltage power distribution room of this patent includes the following steps:

[0050] A: Sensor group installation: install outdoor temperature sensor 1 and outdoor humidity sensor 2 outside the high-voltage power distribution room, and set indoor temperature sensor 3 and indoor humidity sensor 4 inside the high-voltage power distribution room;

[0051] B; control group installation: the output end of A / D converter 5 is connected to single-chip microcomputer 6, the output end of button unit 8 and the input end of display unit 9 are connected to single-chip microcomputer 6, the input end of single-chip microcomputer 6 and drive circuit 7 connect;

[0052] C: The connection between the sensor group and the control group: connect the outdoor temperature sensor 1, the outdoor humidity sensor 2, the indoor temperature sensor 3 and the indoor humidity sensor 4 to the input end of the A / D c...

Embodiment 2

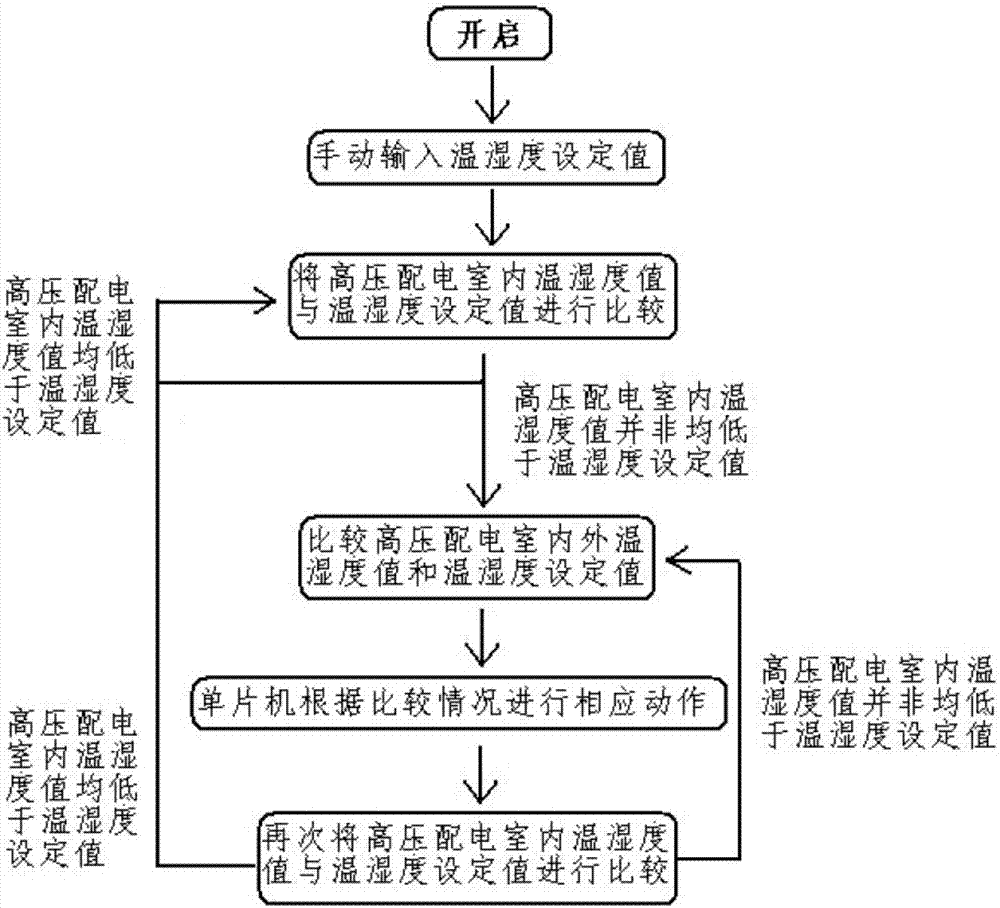

[0075] For a high-voltage power distribution room, the temperature is required to be below 30°C, the humidity is required to be below 40%RH, the temperature margin is 5°C, and the humidity margin is 5%RH. Use this device to control the temperature and humidity of the high-voltage power distribution room. Control; when the outdoor temperature of the high-voltage power distribution is 35°C and the humidity is 50%RH, while the temperature inside the high-voltage power distribution room is 40°C and the humidity is 60%RH, the device first controls the dry and wet gas port switching device 13 to close the dry gas port , the dehumidifier air intake switching device 14 closes the indoor air inlet, then starts the explosion-proof axial flow fan 10 to replace the indoor and outdoor air, and starts the dehumidifier 12 to directly dehumidify the air entering the room. When the indoor and outdoor air temperatures are balanced, Then the device controls the explosion-proof axial flow fan 10 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com