A kind of preparation method of shape memory polyurethane

A technology of polyurethane and polyurethane prepolymer, which is applied in the field of preparation of shape memory polyurethane, can solve the problems of poor memory effect, low shape fixation rate and shape recovery rate, and cannot be widely used, and achieves stable structure and good shape memory. Effects, easily adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The present invention provides a kind of preparation method of shape-memory polyurethane, and this method mainly comprises the following steps:

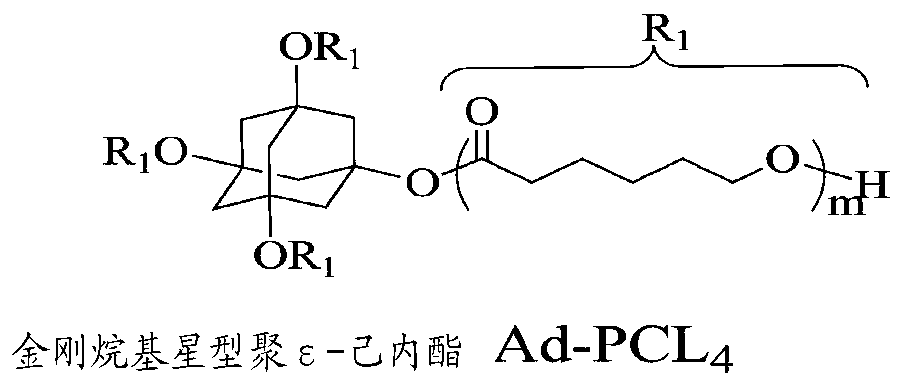

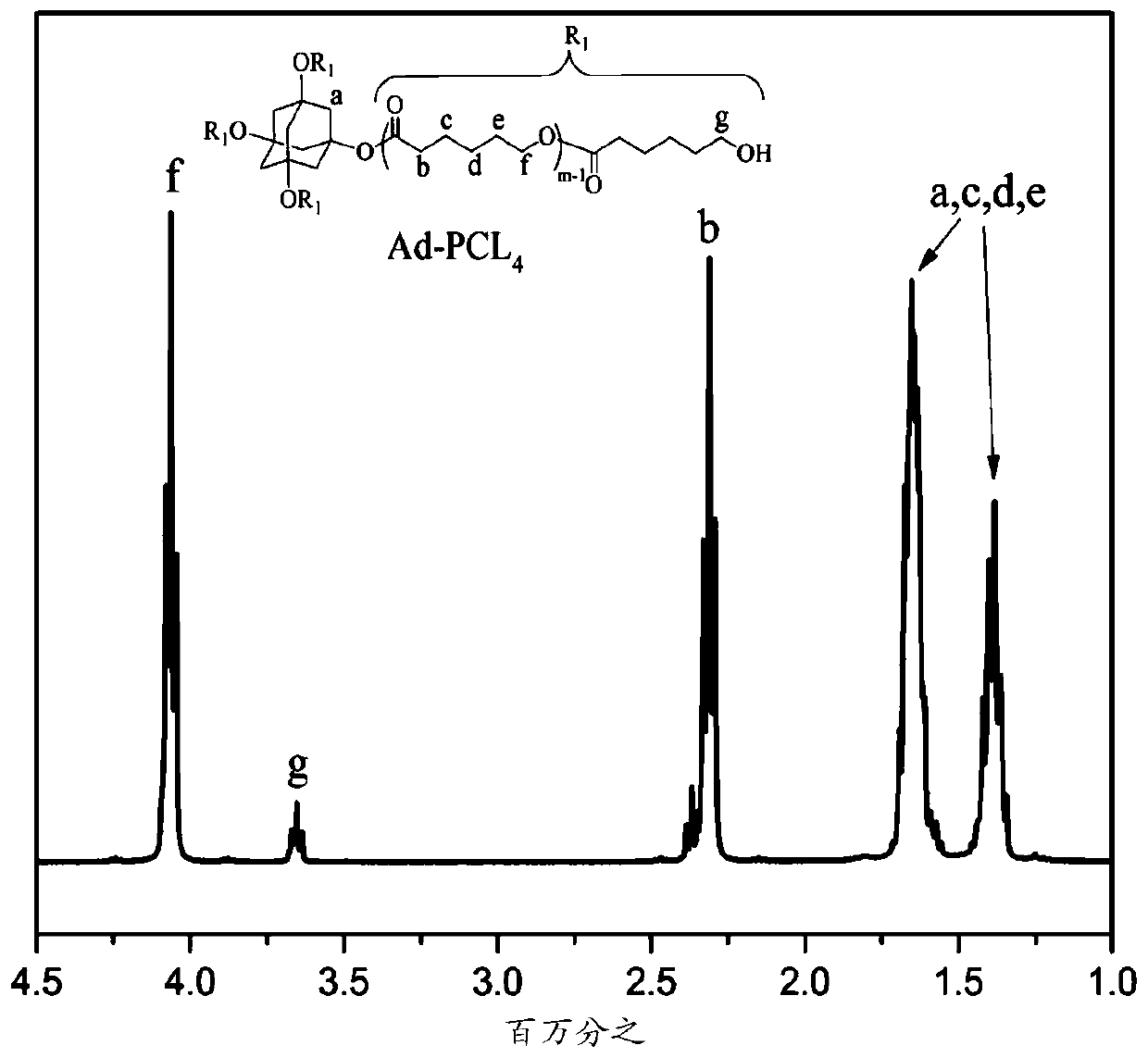

[0019] React 1,3,5,7-tetrahydroxyadamantane, ε-caprolactone, catalyst and solvent under the conditions of inert gas and 70-130°C for 20-50 hours to obtain adamantyl star-shaped polyε- Caprolactone, the molar ratio of the 1,3,5,7-tetrahydroxyadamantane and the ε-caprolactone is 1:40~240;

[0020] Mix the adamantyl star-shaped polyε-caprolactone with long-chain diol and diisocyanate evenly, add the catalyst and the solvent, and react at 50-100°C for 3-9 hours to obtain isocyanate-terminated polyurethane Prepolymer, the mass ratio of the adamantyl star polyε-caprolactone to the long-chain diol is 9:1~1:9;

[0021] A linking agent is added to the polyurethane prepolymer, so that the linking agent reacts with the isocyanate in the polyurethane prepolymer to obtain the adamantyl crosslinked shape memory polyurethane.

[0022] In t...

Embodiment 1

[0030] Under the protection of an inert gas, add 1,3,5,7-tetrahydroxyadamantane, ε-caprolactone, a catalyst and a solvent into the reaction flask, the catalyst is stannous isooctanoate, the solvent is toluene, through freezing and pumping 1. After removing oxygen and water by three cycles of ventilation, the reaction bottle was placed in an oil bath and heated to 90°C. After reacting for 24 hours, the solvent was removed by rotary evaporation to obtain adamantyl star polycaprolactone. Wherein, the molar ratio of 1,3,5,7-tetrahydroxyadamantane to ε-caprolactone is 1:60, stannous isooctanoate is 0.1wt%, and the solvent is 70wt%.

[0031] The adamantyl star poly-caprolactone obtained is added to 1,6-hexamethylene diisocyanate, poly-ε-caprolactone diol (molecular weight 5000), catalyst stannous octanoate, reaction solvent N, In the mixed system of N-dimethylformamide, stir evenly, and react at 80° C. to obtain a prepolymer. Then add small 1,4-butanediol to connect the prepolymer,...

Embodiment 2

[0033] Under the protection of an inert gas, add 1,3,5,7-tetrahydroxyadamantane, ε-caprolactone, a catalyst and a solvent into the reaction flask, the catalyst is stannous isooctanoate, the solvent is toluene, through freezing and pumping 1. After removing oxygen and water by three cycles of ventilation, the reaction bottle was placed in an oil bath and heated to 90°C. After reacting for 24 hours, the solvent was removed by rotary evaporation to obtain adamantyl star polycaprolactone. Wherein, the molar ratio of 1,3,5,7-tetrahydroxyadamantane:ε-caprolactone is 1:100, stannous isooctanoate is 0.1wt%, and the solvent is 70wt%;

[0034] The adamantyl star poly-caprolactone obtained is added to 1,6-hexamethylene diisocyanate, poly-ε-caprolactone diol (molecular weight 5000), catalyst stannous octanoate, reaction solvent N, In the mixed system of N-dimethylformamide, stir evenly, and react at 80° C. to obtain a prepolymer. Then add small 1,4-butanediol to connect the prepolymer, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

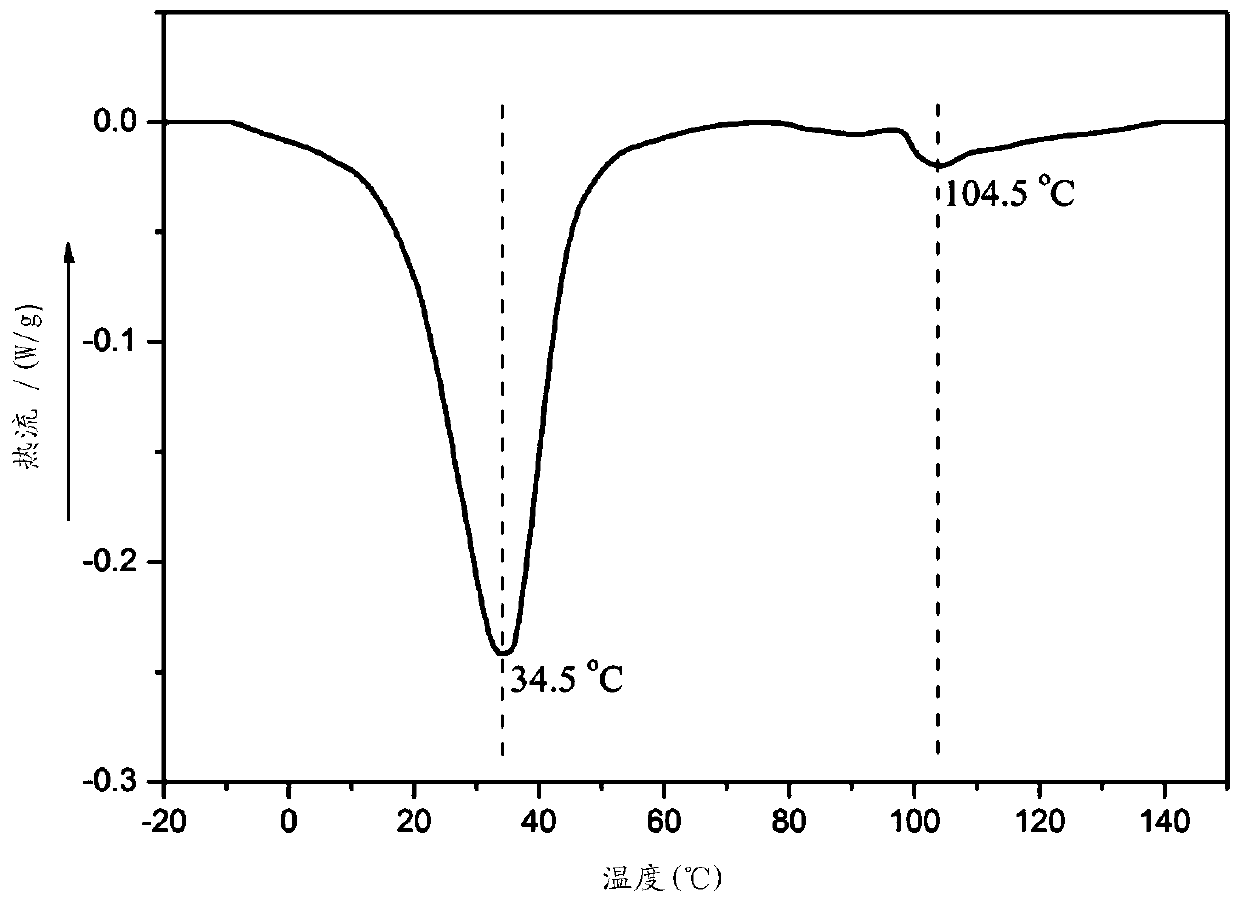

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com