Gypsum plasterboard production system

A paper-faced gypsum board and gypsum board technology, which is applied in the direction of manufacturing tools, surface layering devices, ceramic molding workshops, etc., can solve the problems of inability to guarantee product quality, low production efficiency, and large labor costs, so as to reduce manpower The effect of cost input, improvement of production efficiency and product quality, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

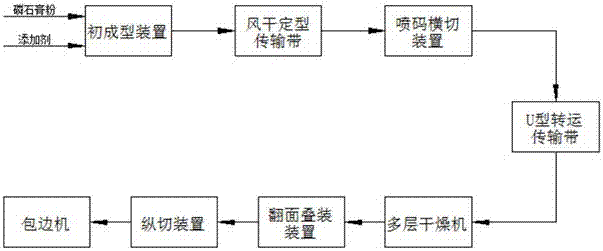

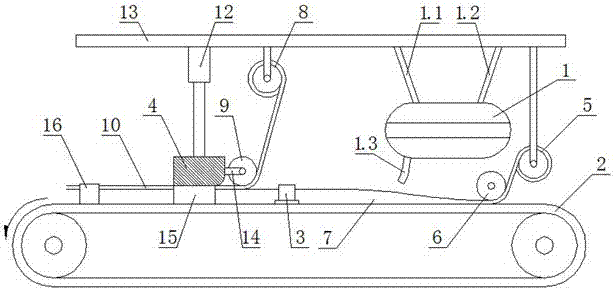

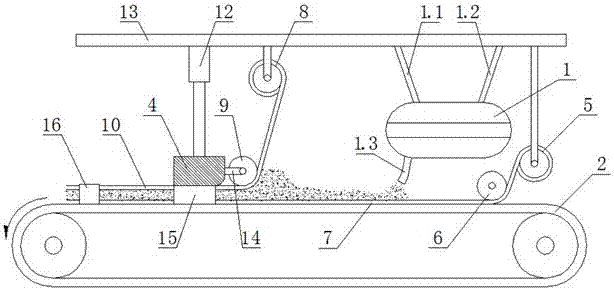

[0069] Such as figure 1 As shown, the paper-faced gypsum board system includes a primary forming device, a coding cross-cutting device, a multi-layer dryer, a turning and stacking device, a slitting device, and an edge-wrapping machine. Raw phosphogypsum powder and additives are injected into the primary forming The entrance of the device, the outlet of the primary forming device and the entrance of the inkjet cross-cutting device are connected by an air-drying and shaping conveyor belt, and the outlet of the inkjet cross-cutting device and the feed port of the multi-layer dryer are connected by a U-shaped transfer conveyor belt Connection, the discharge port of the multi-layer dryer is connected with the edge wrapping machine through the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com