Vibrating screen

A sieve mesh and sieve mesh technology, which is applied in the field of electrical machinery and equipment, can solve the problems of time-consuming and labor-intensive, waste of resources and low efficiency, and achieve the effects of convenient use, energy saving, efficiency improvement and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

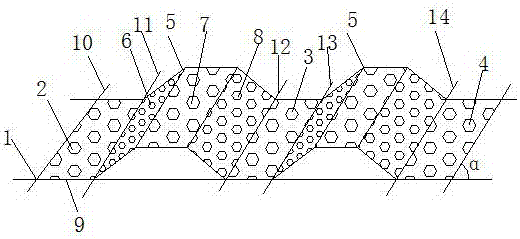

[0012] Such as figure 1 A vibrating screen is shown, comprising an inclined support body 1 that forms an angle α with the horizontal plane. The inclined support body 1 is sequentially installed with a first screen 2, a second screen 3, and a third screen 4. The first screen 2, the second screen 3, and the third screen 4 are provided with two identical screen groups 5 at intervals. The screen groups 5 include a first slope screen 6, the first A fourth screen 7 is fixedly connected to the slope screen 6, and a second slope screen 8 is fixedly connected to the fourth screen 7.

[0013] The inclined support 1 is composed of two first long support rods 9 and two second short support rods 10 parallel to each other. The first long support rods 9 and the second short support rods 10 are perpendicular to each other. A third short support rod 11, a fourth short support rod 12, a fifth short support rod 13, and a sixth short support rod 14 which are parallel to the second short support rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com