A carbon-containing composite semipermeable membrane for photoevaporating water, its preparation method and application

A composite semipermeable membrane and light evaporation technology, which is applied in the field of composite semipermeable membranes and carbon-containing composite semipermeable membranes, can solve the problems of high price of precious metal gold, achieve low cost, simple preparation, and good light-to-heat conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

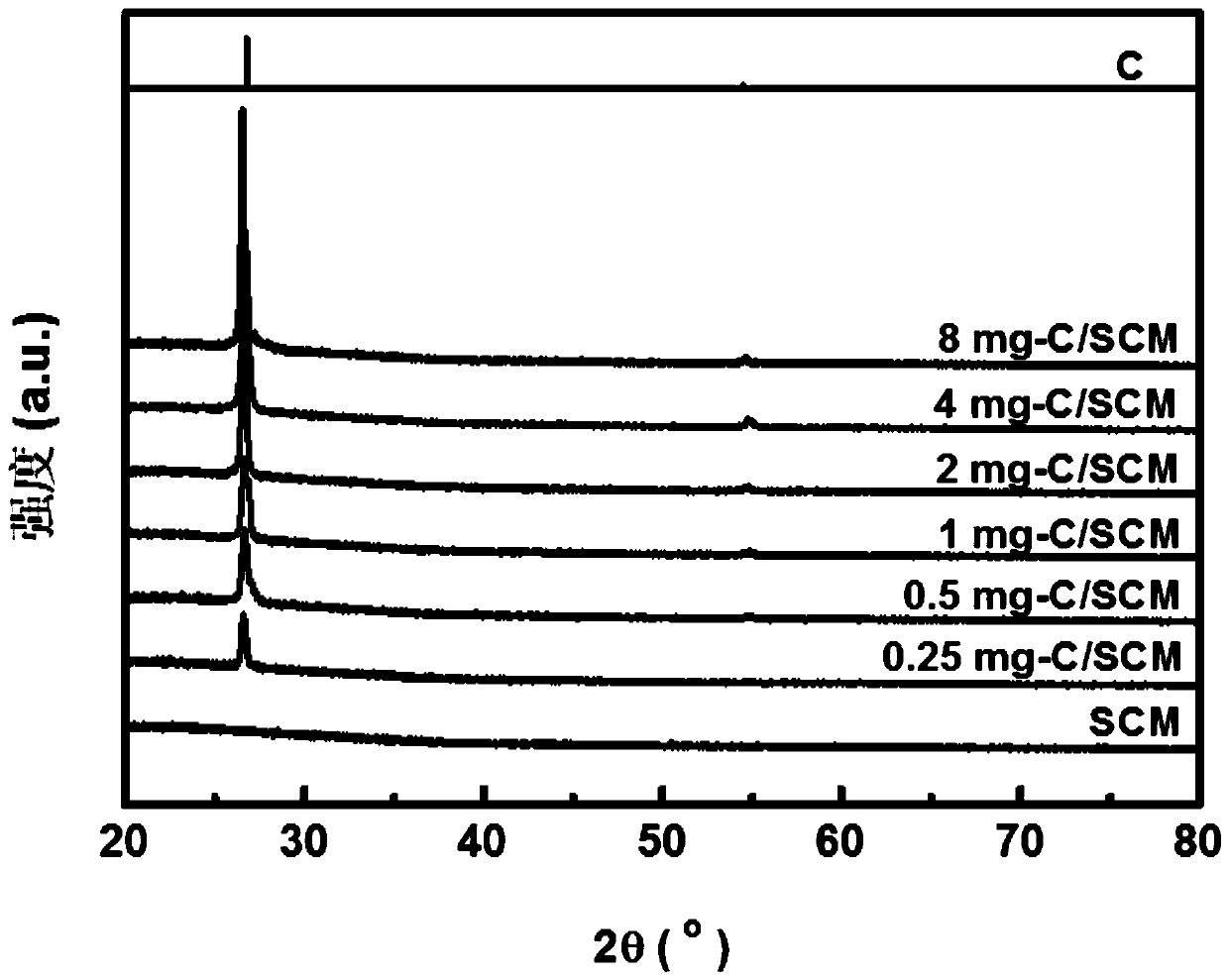

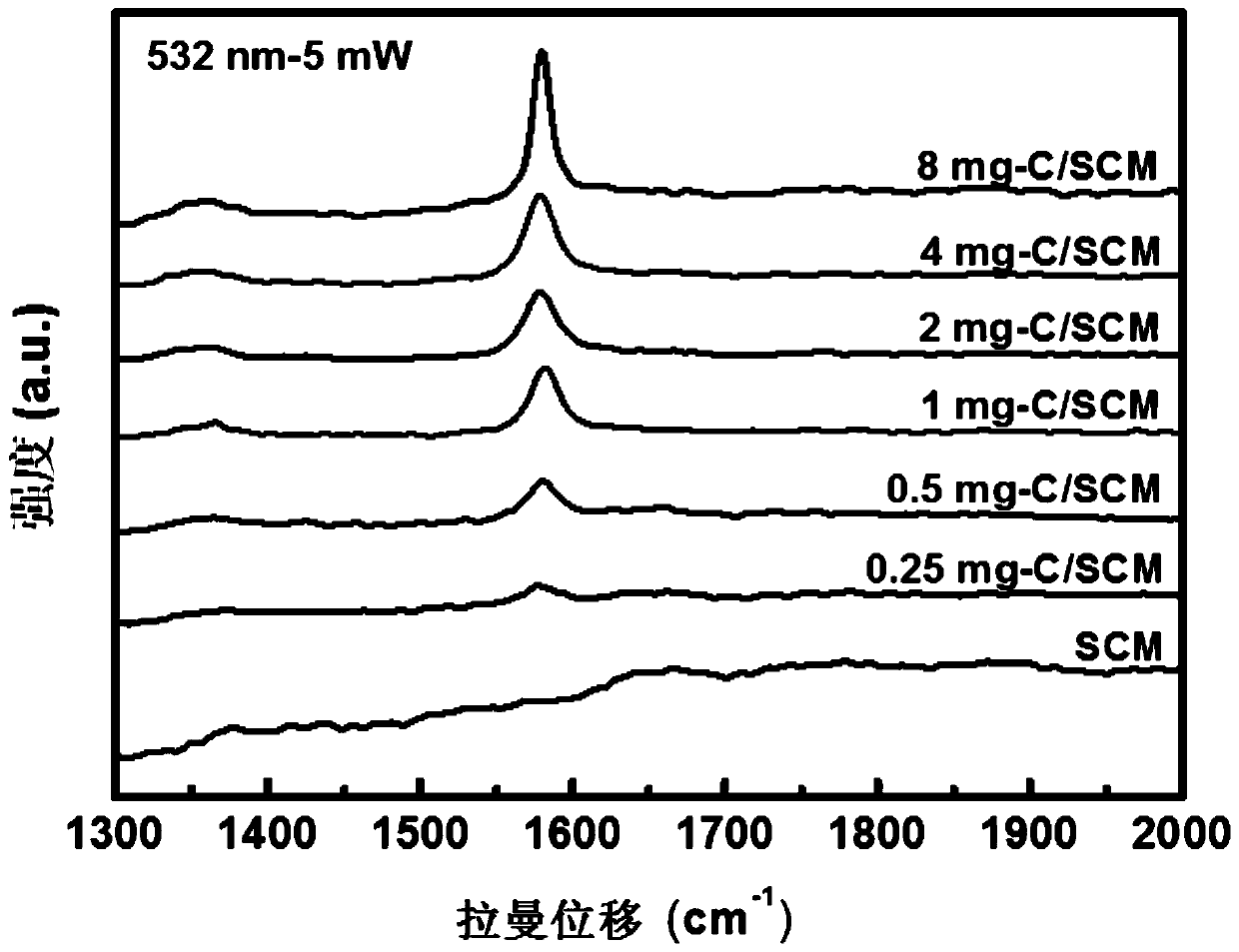

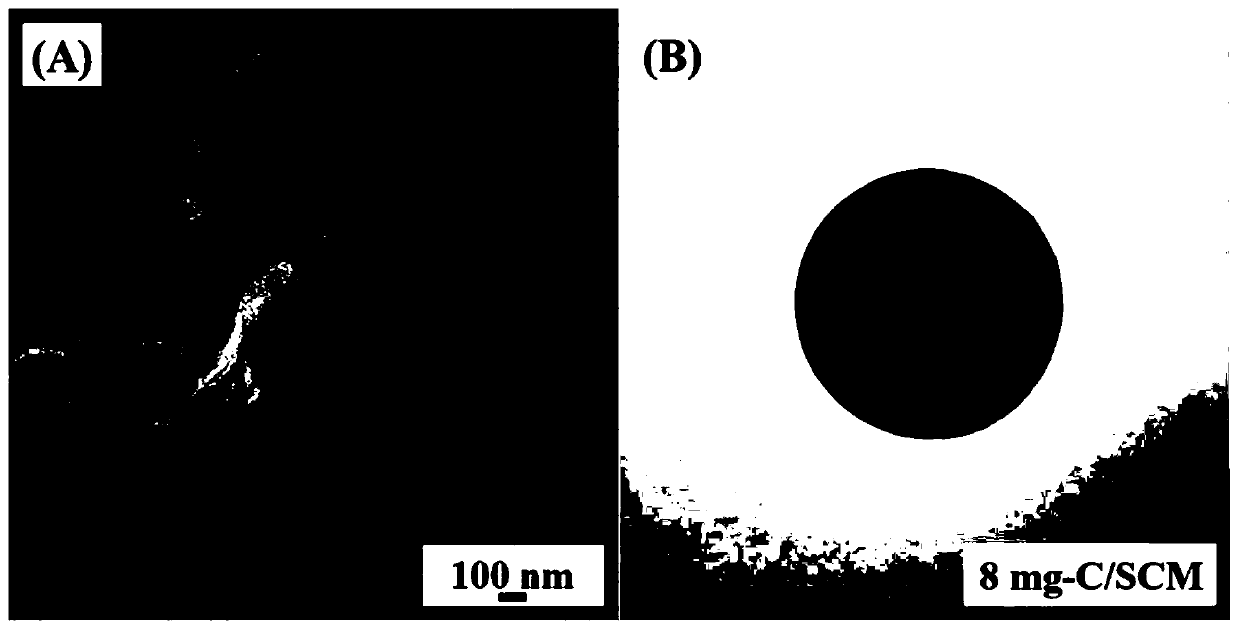

[0032] Add 3.375 mg of graphitic carbon to 6 mL of the above semipermeable membrane precursor solution, and mechanically stir for 30 minutes to obtain a uniformly mixed mixed solution; take out 2 mL of the mixed solution, add it to the bottom of a 500 mL beaker with a diameter of 75 mm, and dry it naturally to form a film. Cut it into a circular film with a diameter of 35 mm, and prepare a carbon-containing composite semipermeable membrane with a thickness of about 100 μm and a content of 0.25 mg.

Embodiment 2

[0034] Add 6.75 mg of graphitic carbon to 6 mL of the above-mentioned semipermeable membrane precursor solution, and mechanically stir for 30 minutes to obtain a uniformly mixed mixed solution; take out 2 mL of the mixed solution, add it to the bottom of a 500 mL beaker with a diameter of 75 mm, and dry it naturally to form a film. Cut it into a circular film with a diameter of 35 mm, and prepare a carbon-containing composite semipermeable membrane with a thickness of about 100 μm and a content of 0.5 mg.

Embodiment 3

[0036] Add 13.5 mg of graphitic carbon to 6 mL of the above semipermeable membrane precursor solution, and mechanically stir for 30 minutes to obtain a uniformly mixed mixed solution; take out 2 mL of the mixed solution, add it to the bottom of a 500 mL beaker with a diameter of 75 mm, and dry it naturally to form a film. Cut it into a circular film with a diameter of 35 mm, and prepare a carbon-containing composite semipermeable membrane with a thickness of about 100 μm and a content of 1 mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com