A packed tower with anti-clogging and anti-wall flow

A packed tower and anti-clogging technology, which is applied to the chemical method, separation method, and separation of dispersed particles that make liquid and gas medium react, and can solve the problem of affecting the uniformity of liquid distribution, affecting mass transfer, heat transfer, and reducing separation efficiency. and other problems to achieve the effect of avoiding clogging, reducing gaps and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

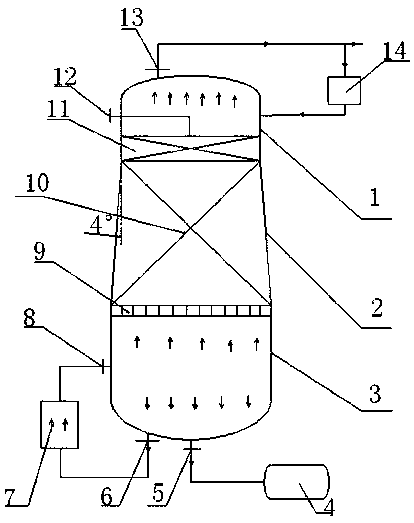

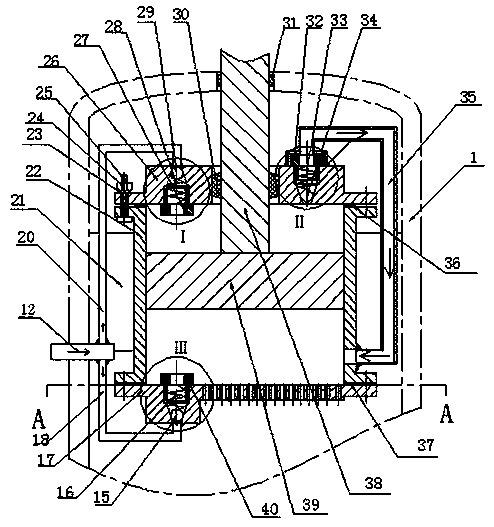

[0029] As shown in the figure, an anti-blocking and anti-wall flow packed tower of the present invention includes a cylinder body, a packing 10 located in the cylinder body and a packing support grid 9, a liquid outlet 5 is arranged below the cylinder body, and the liquid outlet 5 A finished product tank 4 is connected, a feed inlet 12 is provided above the cylinder, a gas outlet 13 is also provided on the cylinder, a filler 10 is installed in the cylinder, and the lower part is supported by a filler support grid 9, and the cylinder is formed by the first part 1. The second part 2 and the third part 3 are connected sequentially from top to bottom. The second part 2 is in the shape of a truncated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com