Front waist sticker of paper diaper and production process of front waist sticker

A technology of diapers and front waist stickers, which is applied in the field of sanitary products, can solve the problems of complicated front waist stickers process, skin allergies, and sticking position deviation of front waist stickers, etc., achieve good liquid diffusion performance, increase stretching range, and improve finished products rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

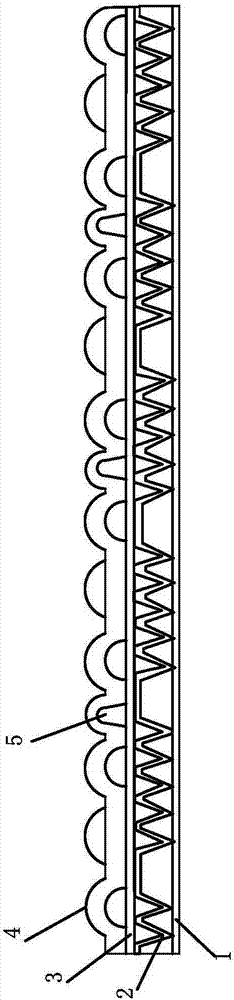

[0028] Such as figure 1 , 2 As shown, the technical solution of the present invention is a front waist sticker for diapers, including a waist circumference part and a waist sticker part. The waist circumference part 6 includes an inner non-woven fabric layer 1, an elastic layer 2 and The outer non-woven fabric layer 3, the inner non-woven fabric layer 1 is compounded with a waterproof plastic film, and the elastic layer 2 is provided with outwardly convex or inwardly concave bumps on the inner non-woven fabric layer 1 Texture, the outer non-woven fabric layer 3 is provided with semi-elliptical spherical protrusions 4 and strip-shaped arc-shaped protrusions 5, and the two sides of the waist circumference part 6 extend laterally for connecting the waist circumference part. The waist sticker part includes a connection part 7 for connecting the waist part 6, a magic buckle 8 for buckling the abdomen part, the connection part 7 and the magic buckle 8 are connected by an elastic be...

Embodiment 2

[0040] Such as figure 1 , 2 As shown, the technical solution of the present invention is a front waist sticker for diapers, including a waist circumference part and a waist sticker part. The waist circumference part includes an inner non-woven layer, an elastic layer and an outer non-woven cloth layer, the inner non-woven fabric layer is compounded with a waterproof plastic film, the inner non-woven fabric layer is provided with an outwardly protruding or inwardly concave concave-convex texture, and the outer non-woven fabric layer is The woven fabric layer is provided with semi-ellipse-shaped protrusions and strip-shaped arc-shaped protrusions, and the two sides of the waist circumference part are respectively extended transversely for connecting the waist circumference part. The connecting part of the waist part and the magic buckle used to buckle the abdominal part, the connecting part and the magic buckle are connected by an elastic belt, and a tear-off part is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com