A high-density non-stop round straw baling method and baler

A technology of round straw bales and balers, which is applied to the baling method of high-density non-stop round straw bales and the field of balers, can solve the problems of uneven density of round straw bales, shutdown operations, etc. , the effect of increasing the weight and reducing the silage operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

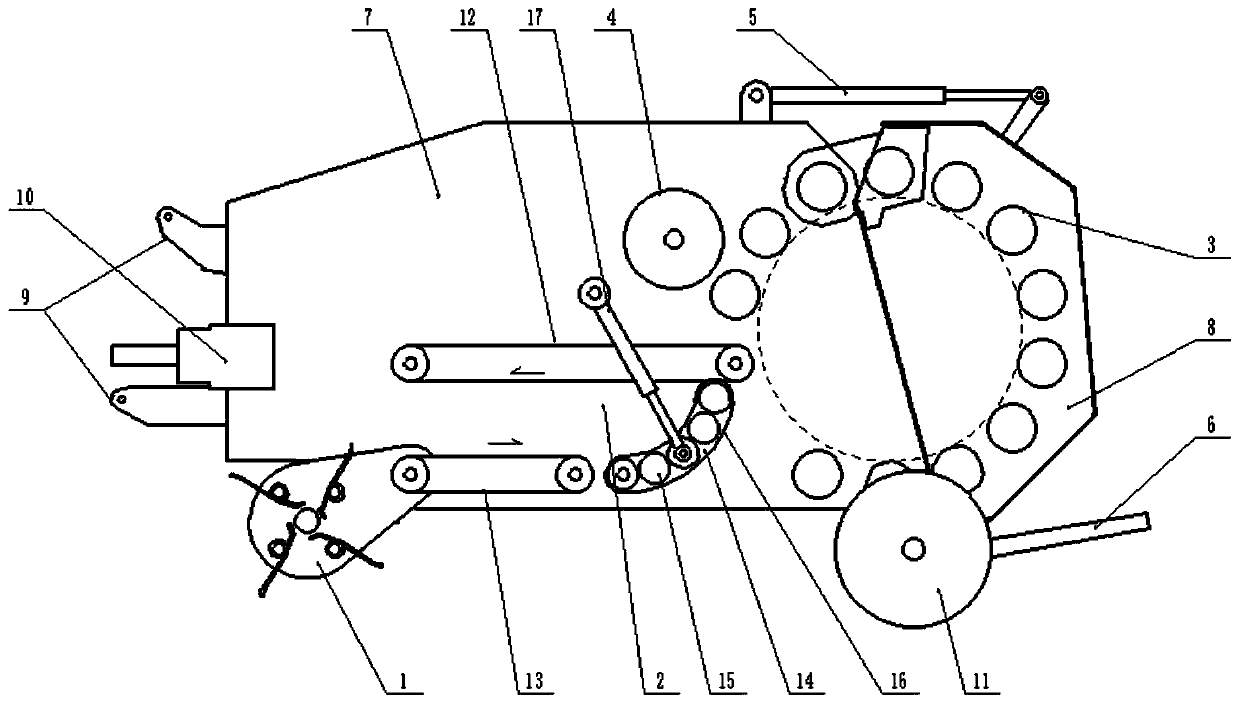

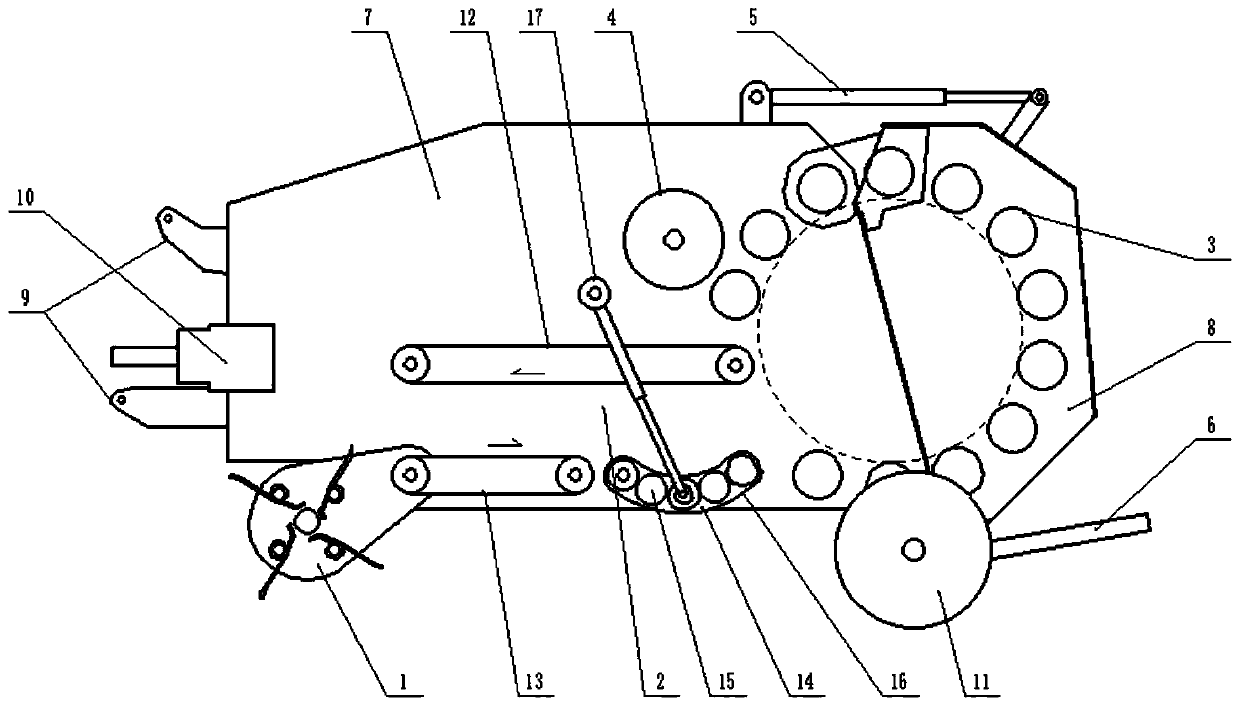

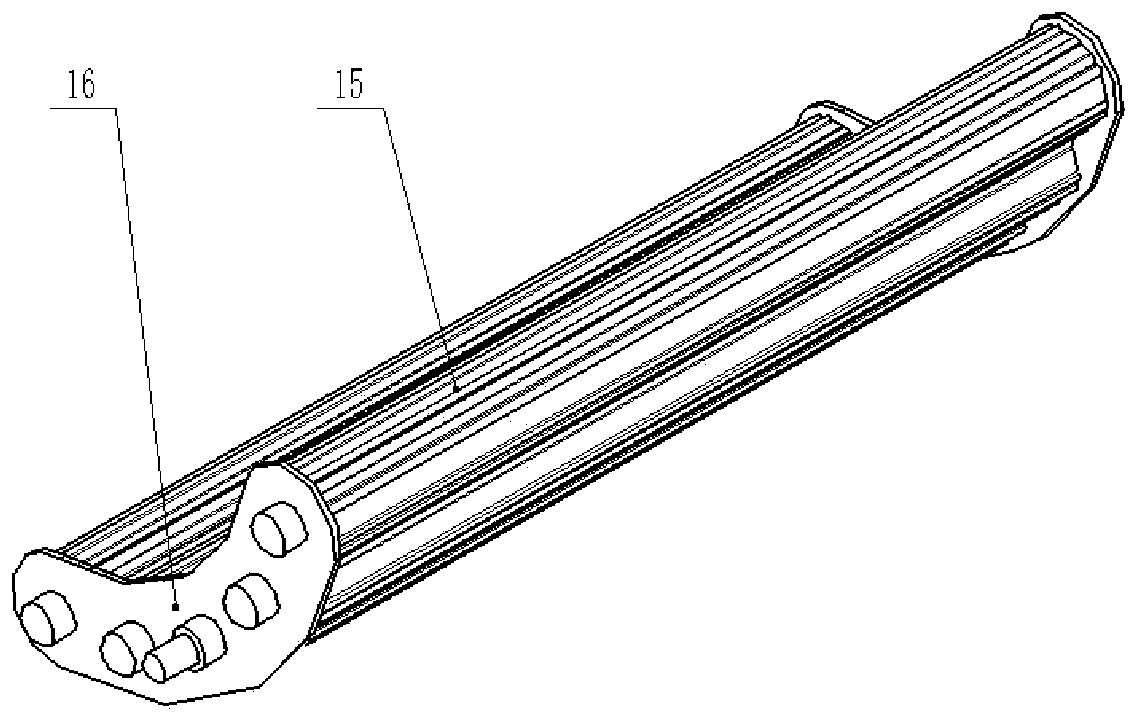

[0028] The strapping machine described in this embodiment sees figure 1 , figure 2 and image 3 shown.

[0029] The baler described in this embodiment adopts a high-density non-stop round bale bundling method. In the baler, a grass core is first formed so that the density of the grass core is the same as that of the rest of the round bale; The outer layer of the core continues to wind the grass to form the final round bale; then the round bale is bundled and unloaded from the baler. During this process, the baler makes the next grass core synchronously, so that the baler can not stop continuous round bales. The specific bundling steps are as follows:

[0030] (1) Grass core formation stage: the forage (grass or crop stalks) picked up by the spring tooth type picker 1 enters the pre-compression device 2, and the pre-compression device 2 is in a closed state at this time, and the forage is conveyed by the lower conveyor belt 13, In contact with the floating steel roller gr...

Embodiment 2

[0041] The structure of the strapping machine described in this embodiment is basically the same as that of the strapping machine described in Embodiment 1, the difference is that the strapping machine described in this embodiment is equipped with a power unit and a walking device, forming a self-propelled Baler.

[0042] Another difference is that five floating steel rollers 15 in the floating steel roller group 14 of the strapping machine described in this embodiment are arranged in a straight line, and the floating side walls are linear plates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com