Thermoelectric material, thermoelectric conversion element, and module group composed of combination of thermoelectric conversion elements and pi-type module group made of thermoelectric material and pi-type module group made of thermoelectric material other than such pi-type module group

A technology of thermoelectric conversion and thermoelectric materials, applied in the direction of electrical components, thermoelectric devices, thermoelectric devices that only use the Peltier or Seebeck effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

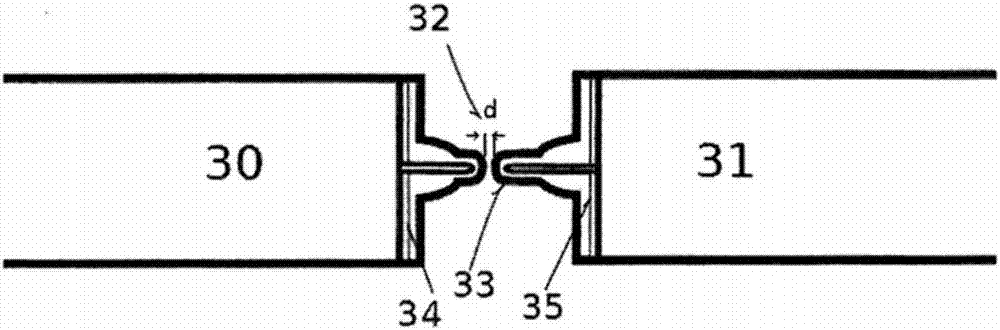

[0182] Figure 13 An embodiment is shown focusing on a part of the i-th generation TCE made of series Π-modules whose legs are thermoelectric materials 130 and 131 with polarities different from each other and a space 132 with an insulator 135. By using an insulator possibly controlled by an actuator, i.e. Figure 13 One of the structural components omitted in , between the insulating material 135 and the WS good conductor 138 , regulates the heat flow of the heat transfer in the thermoelectric material 139 so that laminar flow occurs. Heat from WS good conductor 133 reaches WS good conductor 138 and passes through insulator 135 . The spaces and the steeples and / or "sharp corners of the thread" etc. established in the spaces can be altered for the bridging material in the bridging spaces. The radiation energy loss between the WS conductors facing each other in the space and / or bridge space is much larger than that of the Π-type module, where the area ratio of the latter to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com