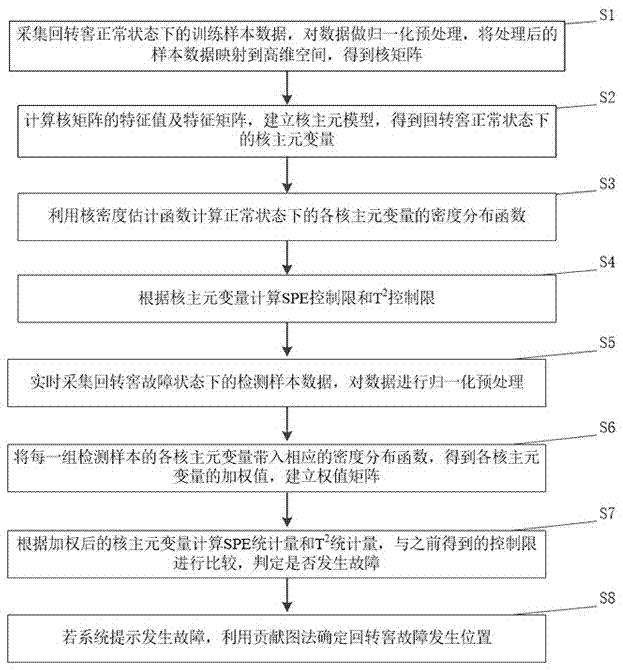

Rotary kiln fault diagnosis method based on weighted kernel principal component analysis (WKPCA)

A technology of nuclear principal component analysis and fault diagnosis, applied in resources, instruments, manufacturing computing systems, etc., can solve problems such as hidden dangers in the stable operation of precalciner kilns, system monitoring, and limited application of cement rotary kilns, and achieve reasonable and accurate steps Effective monitoring, effectiveness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

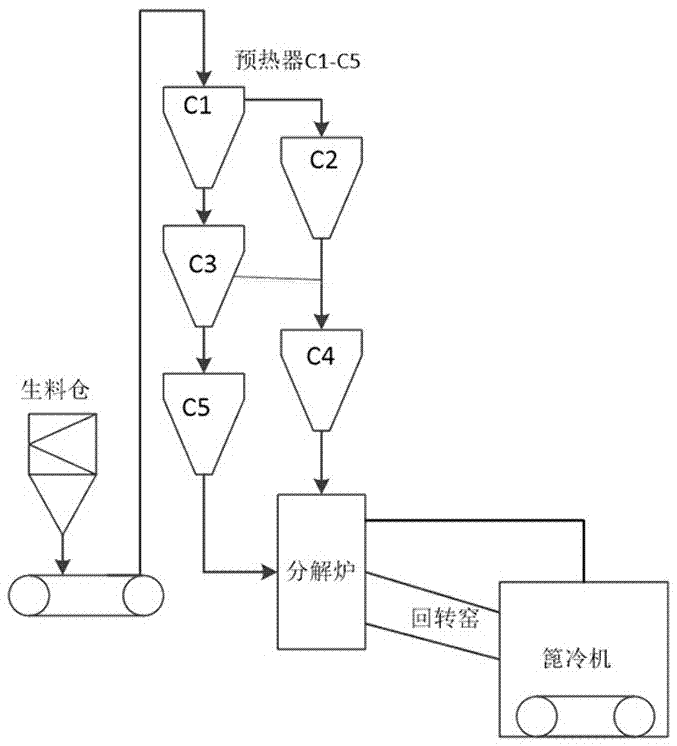

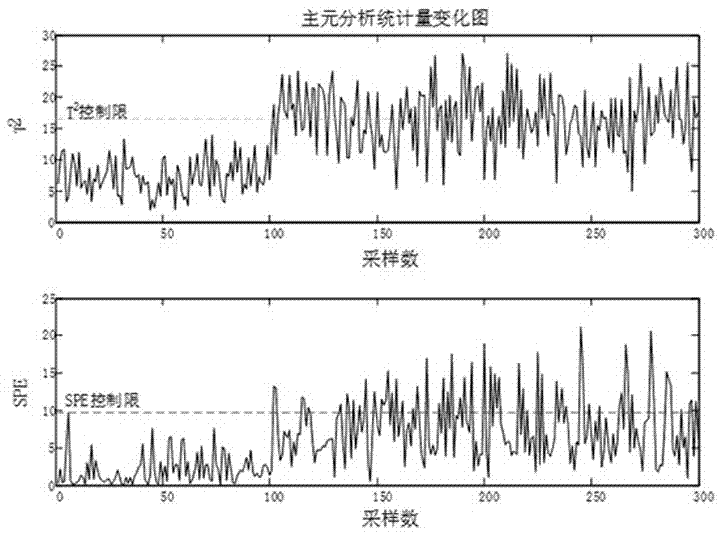

[0070] Taking a large cement rotary kiln with a daily output of 2500t of clinker as an example to carry out simulation experiments, for the fault detection of the entire precalcining system, the temperature and pressure of each key position should be the focus of detection. Taking the fault of variable 1 kiln tail temperature as an example, fault 1 is a sudden rise in the temperature of the kiln tail, and the fault is set as a step fault in which the temperature of the system rises at the kiln tail from the 101st sampling point. First, the number of pivots is selected according to the criterion that the cumulative variance contribution rate is greater than 0.8.

[0071] The principal component analysis method and the weighted kernel principal component analysis method are used for fault detection respectively, and the SPE and T 2 Control limits and statistics. From image 3 It can be seen that in the process of using the PCA method for fault detection, the abscissa indicates...

no. 2 example

[0075] Taking the temperature drift at the kiln tail as the fault point 2, the variable 1 fault is set as the fault that the temperature changes slowly at the kiln tail at the time k=101, and the fault diagnosis test is carried out by using this method, from Figure 6 It can be seen that the principal component analysis can detect the temperature drift fault, although it can detect that the two statistics exceed the control limit, but the fault is detected at k=115, and the alarm cannot be issued in time.

[0076] but from Figure 7 It can be seen that the detection method after weighting is at 8 moments after the temperature drift, that is, at the moment k=108, the detection statistics completely exceed the control limit, and the fault is detected. Compared with the single PCA method, it is more timely and accurate. The generation of failure.

[0077] The rotary kiln fault diagnosis method based on weighted kernel principal component analysis (WKPCA) provided by the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com