Weighing and charging machine and application method thereof

A charging machine and charging technology, which is applied in the field of gunpowder and explosive charging, can solve the problems of difficult automatic operation, low work efficiency, high labor intensity, etc., and achieve compact structure, high labor intensity and reasonable layout. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

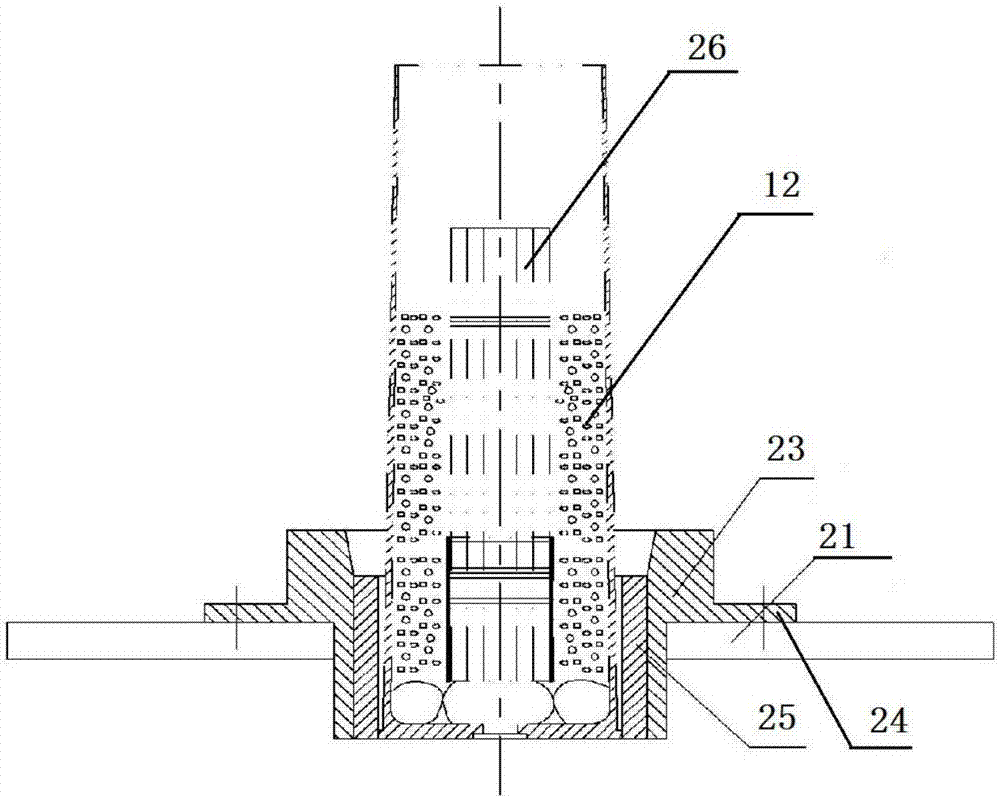

[0024] Such as Figure 1-2 Shown, a kind of weighing charging machine, comprises automatic weighing charging machine and vibration machine; Described automatic weighing charging machine comprises frame, hopper 1, charging hopper 2, electronic balance 3, roughly weighs Device 4, fine scale device 5, drug guiding device 6, drug guiding device rotation mechanism 7, tooling release mechanism 8, translation frame 9, drug charging tooling 10; the hopper 1 is fixedly installed on the frame, The hopper 1 is respectively provided with a coarse weighing outlet and a fine weighing outlet, and the coarse weighing outlet and the fine weighing outlet are connected with the rough weighing device 4 and the fine weighing device 5 respectively, and the coarse weighing device 4 and the fine weighing device 5 outlets are respectively connected with the charge hopper 2, and the electronic balance 3 is provided with a central hole, and the charge hopper 2 passes through the center hole of the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com