Coalbed methane extraction system and construction method

A coalbed methane extraction technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of increasing energy consumption, increasing ground construction costs, increasing drilling operation costs, etc., to save workover costs , Reduce energy consumption and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The directional terms such as up, down, left, right, front, back, front, back, top, and bottom that are mentioned or may be mentioned in this specification are defined relative to the structures shown in the drawings. , the end is defined relative to the engineering implementation, the words "inside" and "outside" refer to the directions toward or away from the geometric center of a specific part, respectively. Use state to change accordingly. Accordingly, these or other directional terms should not be construed as limiting terms.

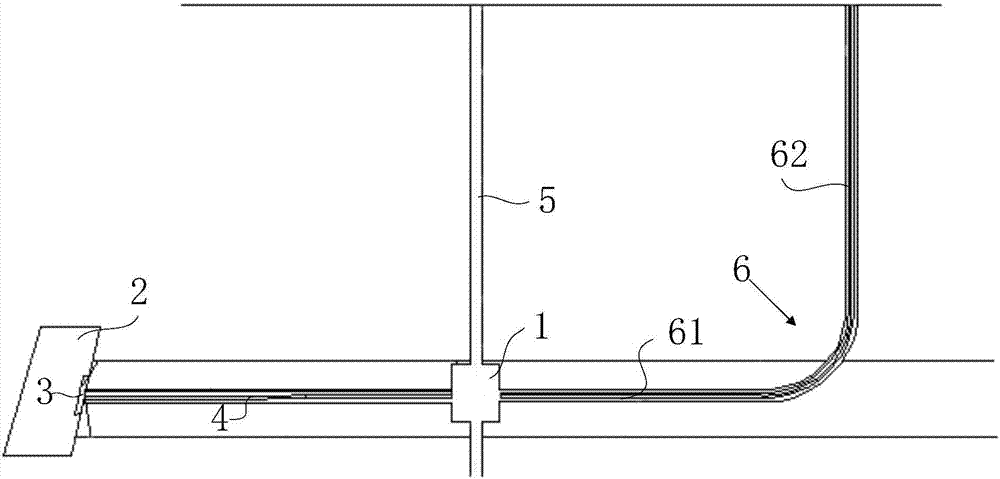

[0021] figure 1 Schematic diagram of the structure of the coalbed methane extraction system provided by the present invention. Such as figure 1 As shown, the present invention provides a coalbed methane extraction system, which includes a communication expansion cavity 1 , a drainage pipeline 3 , and a suction well 4 .

[0022] Please refer to figure 1 , the communication expansion cavity 1 is arranged in the coal seam, and the communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com