Polydimethylsiloxane film modified by reagent containing amino functional group for detecting trinitrotoluene and preparation method thereof

A technology of polydimethylsiloxane and dimethylsiloxane, which is applied in the field of polydimethylsiloxane film and its preparation, can solve the problems of unsuitable portability, high storage cost, and unsuitable recycling of nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

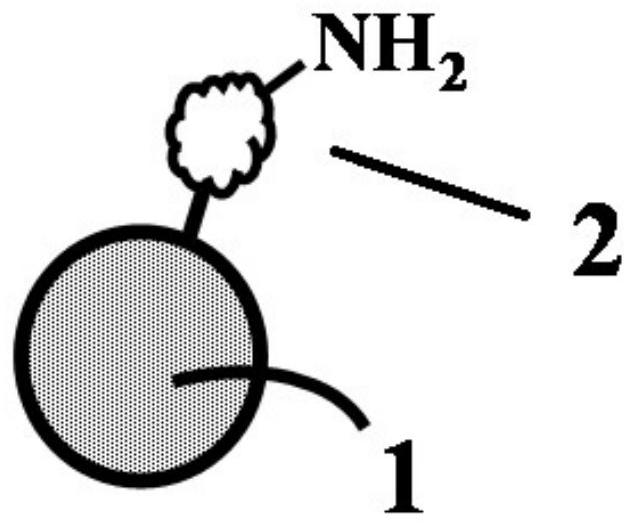

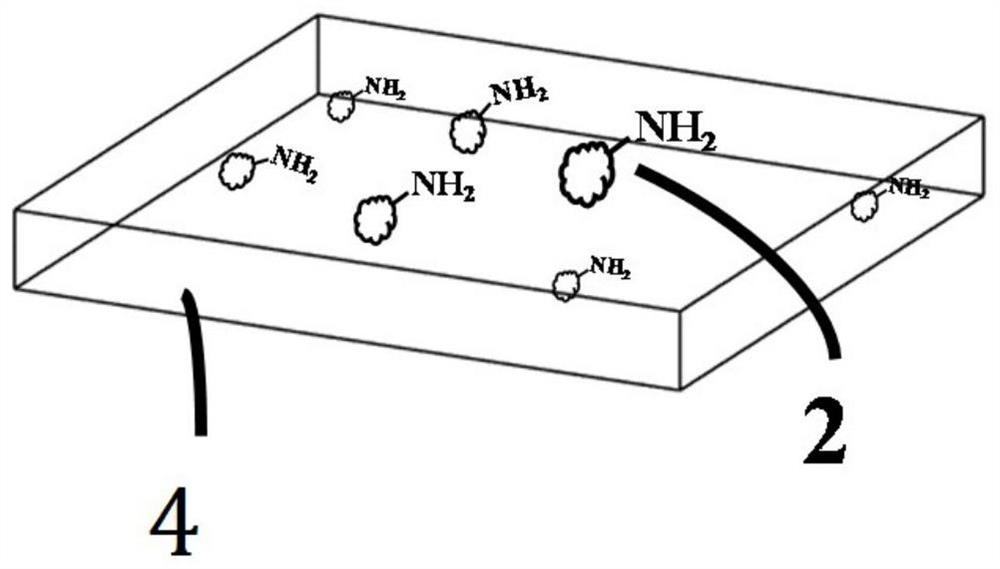

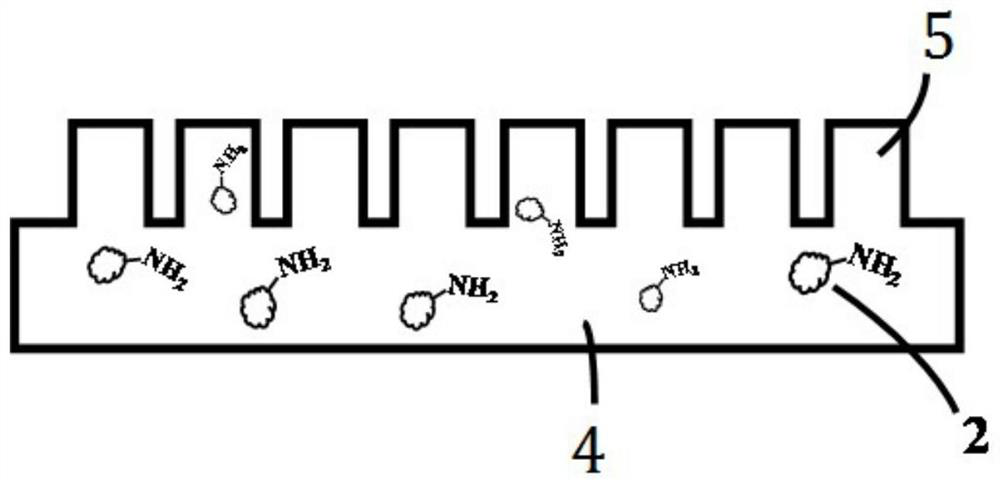

[0043] As an embodiment of the present invention, at least one surface of the polydimethylsiloxane film of the present invention has a special surface structure. Preferably, at least one surface of the polydimethylsiloxane film has one or more of a planar structure, a grid structure, a cylindrical array structure, an inverted cone array structure, and a hemispherical array structure. More preferably, at least one surface of the polydimethylsiloxane film has a grid structure. Grid cylinder array structure Inverted cone array structure Hemispherical array structure The same surface of the polydimethylsiloxane film may have one or several different combinations of the above structures. The introduction of different surface structures is not only beneficial to increase the contact area between the polydimethylsiloxane film and the reagents containing amino functional groups, but also to increase the contact between the polydimethylsiloxane film and the TNT solution. area, which h...

Embodiment 1

[0070] Example 1 Preparation of functional composite polydimethylsiloxane film

[0071]1.1 Materials: The following amino-functional silylating agents were purchased from Aladdin Industrial Corporation: 3-(Ethoxydimethylsilyl)propylamine (APMES, 97%), γ-aminopropyl Diethoxymethylsilane (APDES, 97%), (3-aminopropyl)triethoxysilane (APTES, ≥98%) and 1H, 2H, 2H-tetradecyltrichlorosilane (PFDTS, 96%) without further purification. 2,4,6-Trinitrotoluene solution and 2,4-Dinitrotoluene solution (in methanol, concentration 1 mg / mL) were purchased from Beijing Tanmo Quality Inspection Technology Co., Ltd. Polydimethylsiloxane (PDMS) made of 184 SILICONE ELASTOMIER kit preparation.

[0072] 1.2 Fabrication of composite PDMS films: First, PDMS films were prepared by casting a liquid prepolymer of PDMS base and curing agent at a ratio of 10:1 (w / w) onto a silicon wafer containing an anti-adhesion layer (PFDTS). The mixture was then degassed for 10 minutes to remove air bubbles. Afte...

Embodiment 2

[0075] Example 2 Identification of PDMS film modified with reagent containing amino functional group and its reaction with TNT.

[0076] The key step of the preparation method of the present invention is to prepare a PDMS film modified with a reagent containing an amino functional group with a high amino content, while maintaining the chemical reactivity of the primary amine on the surface and inside of the PDMS film so that it can further react with TNT. The present invention has found a simple method of introducing silylating reagents containing amino functional groups into the surface and interior of PDMS films, that is, immersing the cured PDMS film into a solution of silylating reagents containing amino functional groups (such as 3-aminopropyl (diethoxy ) methylsilane (APDES), 30% v / v ethanol solution). Ethanol can swell the PDMS film and enhance its porous structure, allowing the silylating agent containing amino functional group to diffuse into the PDMS film, forming a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com