Production technology of methyl vinyl silicon rubber

A methyl vinyl silicon and production process technology, applied in the field of organic chemistry, can solve the problems of easy cross-linking of high vinyl raw rubber, unstable vinyl, wide molecular weight distribution, etc. Transparency, narrow molecular weight distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

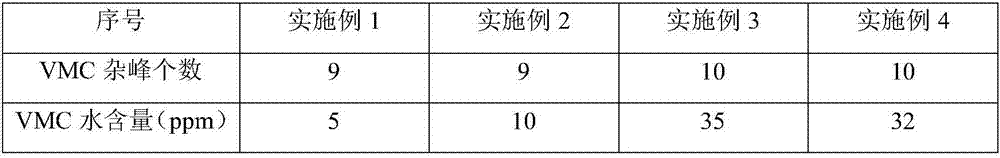

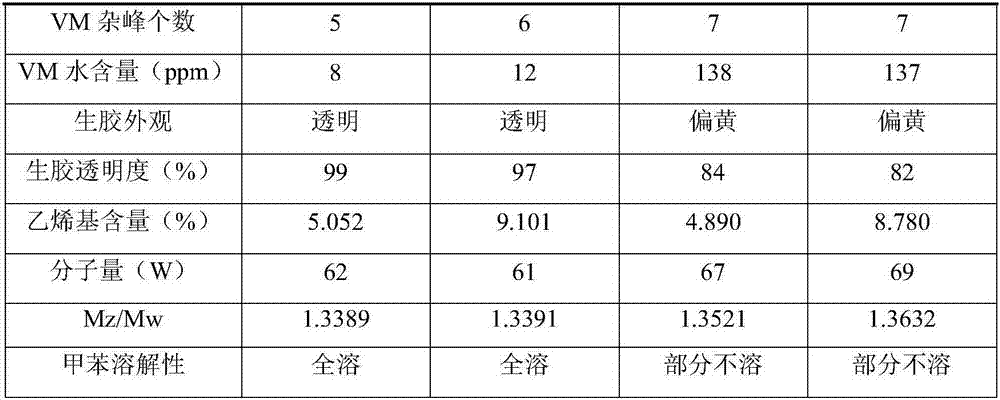

Embodiment 1

[0018] VMC was dehydrated by nitrogen bubbling at a temperature of 125°C and a vacuum of -0.10 MPa. After cooling, it was treated with molecular sieves for 5 days before use. VM was treated with molecular sieves for 7 days before use.

[0019] The dimethylsiloxane mixed ring is filtered through a filter membrane of 0.22um, activated carbon 7kg, and a filter bag with a pore size of 0.5um; the filtered DMC is dehydrated in a dehydration kettle at a dehydration temperature of 100°C and a vacuum of -0.06 MPa, nitrogen bubbling rate 1L / h, dehydration time 3h, dehydration amount 7%.

[0020] Polymerize the treated DMC, VMC, VM, and catalyst at 98°C according to the mass ratio of 100:5.58:0.05:0.02, equilibrate for 5 hours, and the equilibrium temperature is 114°C; the temperature of the balanced material when it reaches the low molecular weight device is 133°C, the temperature is 143°C after flowing through the first section of the tube, and the temperature rises to 153°C after pass...

Embodiment 2

[0022] The VMC was dehydrated by nitrogen bubbling under the conditions of temperature 125°C and vacuum degree -0.09MPa, cooled and treated with molecular sieves for 3 days before use. VMs were treated with molecular sieves for 5 days before use.

[0023] The dimethylsiloxane mixed ring is filtered through a filter membrane of 0.5um, an overlapping filter of 5kg of activated carbon, and a filter bag with a pore size of 0.1um; the filtered DMC is dehydrated in a dehydration kettle at a dehydration temperature of 100°C and a vacuum of -0.07 MPa, nitrogen bubbling rate 2L / h, dehydration time 2.5h, dehydration amount 8%.

[0024] Polymerize the treated DMC, VMC, VM, and catalyst at 95°C according to the mass ratio of 100:10:0.05:0.02, equilibrate for 6 hours, and reach the equilibrium temperature of 115°C; the temperature of the balanced material when it reaches the delowering device is 134°C, the temperature is 141°C after flowing through the first section of tubes, and the temp...

Embodiment 3

[0026] The dimethylsiloxane mixed ring is filtered through a filter bag with a pore size of 1.0um; the filtered DMC and VMC are dehydrated in a dehydration kettle at a dehydration temperature of 85°C, a vacuum of -0.10MPa, and a nitrogen bubbling rate of 15L / h. Time 3h, dehydration 7%;

[0027] Polymerize DMC, VMC, VM, and catalyst at 110°C according to the mass ratio of 100:5.58:0.05:0.02, equilibrate for 4 hours, and reach an equilibrium temperature of 110°C; After the second-stage tube arrangement, the temperature was raised to 165°C; after de-lowering, unqualified high vinyl methyl vinyl silicone rubber was obtained. VMC and DMC were dehydrated at the same time, and the water content was 35ppm; VM was not treated, and the water content was 138ppm. The raw rubber has a yellowish appearance, a transparency of 84%, a vinyl content of 4.890%, a molecular weight of 67W, Mz / Mw=1.3521, and is partially insoluble in toluene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com