Forklift hood

A technology of hoods and forklifts, applied in the direction of lifting devices, etc., can solve the problems of laborious operation, heavy steel plate weight, troubles, etc., and achieve the effect of labor-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

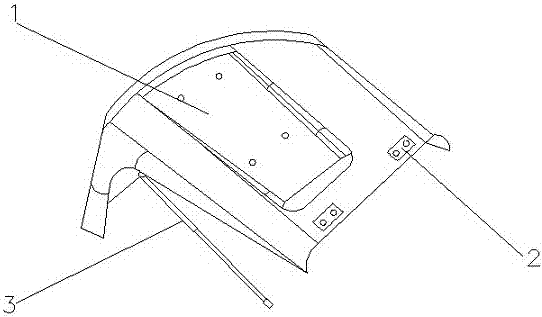

[0008] see figure 1 , a forklift hood, which includes a hood 1, a hinge 2, and a spring brace 3, the hood 1 is provided with a hinge 2 on one side connected to the forklift body, and a spring is also provided on the inner side of the hood 1 Support 3, one end of spring support 3 is connected with machine cover 1, and the other end is fixed on one side of forklift engine.

[0009] When installing the forklift hood, first use a hinge to fix the hood to one side of the forklift engine, which acts as a shaft. When opening, you only need to lift the opposite side, and then fix one end of the spring brace on the engine side , and fix the other end on the inner side of the forklift hood at a certain angle. When the hood is lifted to a certain position, the spring brace will generate an upward force, and the hood will open easily. When the hood is pressed to this position, The spring stays create a downward force and the hood closes automatically.

[0010] For the forklift hood of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com