Method for calibrating faulty wires of capacitive fingerprint acquisition systems and method for self-repairing faulty wires of capacitive fingerprint acquisition systems

A fingerprint collection and calibration method technology, which is applied in the directions of printing image collection, acquisition/organization of fingerprints/palmprints, character and pattern recognition, etc. Consistency etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

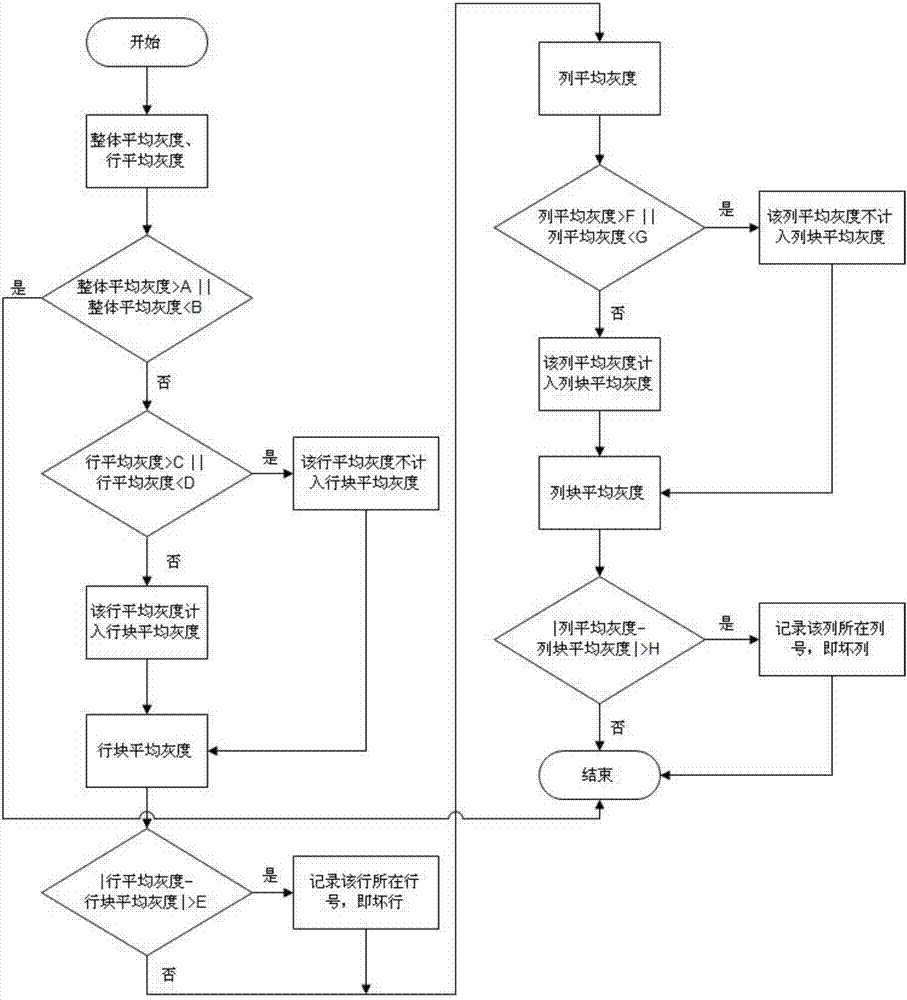

[0026] Described in the present invention is a kind of calibration method of capacitive fingerprint collection system bad line, such as figure 1 As shown, it specifically includes the following steps:

[0027] 1) Calculate the average grayscale of the entire fingerprint image and the average grayscale of each row;

[0028] 2) If the average grayscale of the entire fingerprint image is greater than the threshold A or less than the threshold B, the overall image effect of the judging module does not meet the mass production standard, and it is judged as a defective product, and there is no need for subsequent bad line detection and repair steps, otherwise proceed Step (3);

[0029] 3) If the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com