An integrated method for design and analysis of plate and shell structures based on cad clipping surfaces

A technology for plate and shell structure and design analysis, applied in geometric CAD, instrumentation, electrical digital data processing, etc., can solve problems such as difficulty in popularization and limited versatility, and achieve the effects of easy promotion and use, improved efficiency, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The protection scope of the present invention is not limited only to the description of this embodiment.

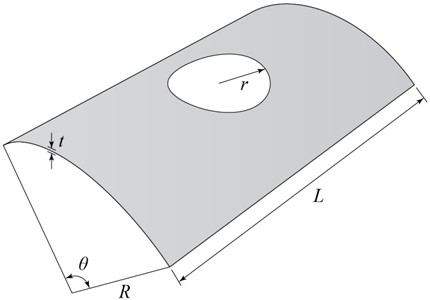

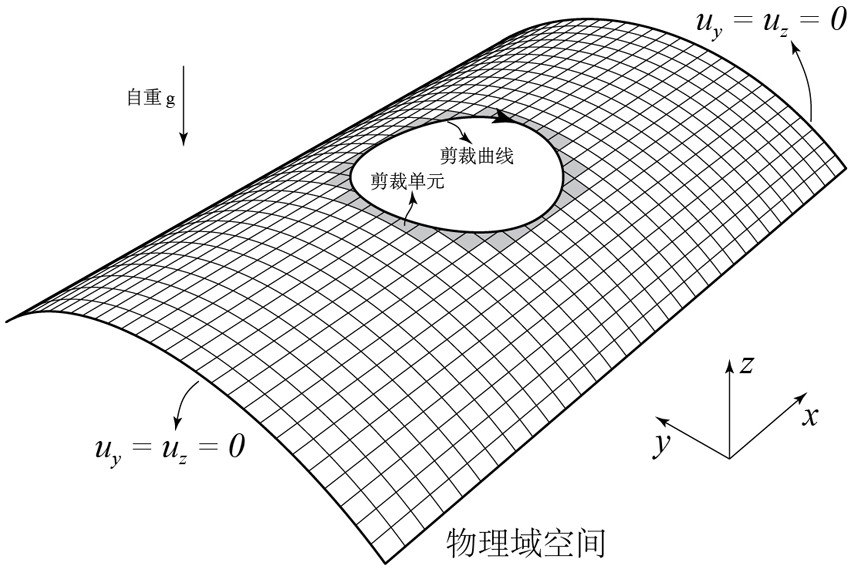

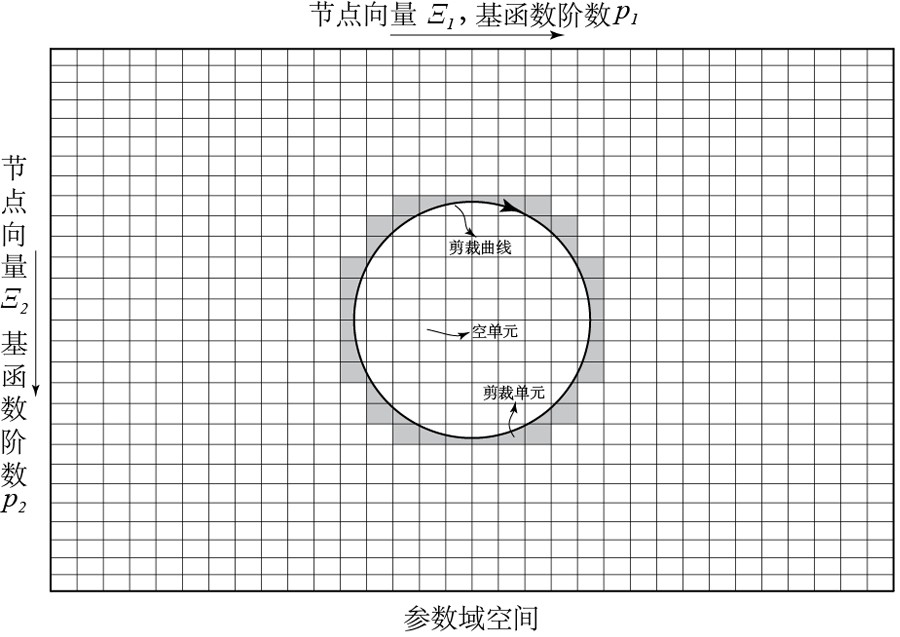

[0033]The integrated method of plate and shell structure design and analysis based on CAD clipping surface is characterized in that, firstly, the method is based on a new isogeometric description, which can directly perform finite element analysis on the model in the geometric modeling software; secondly, the method is based on the product STEP is an international standard for data exchange, so it has strong versatility; thirdly, for the clipping surface commonly used in CAD, this method realizes the fast and accurate integration of the clipped element by extracting and processing the clipping surface information, combined with the mixed element technology, Improved computational efficiency. Concrete steps of the present invention are as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com