A method for solving cutting parameters of cutting teeth of pdc drill under wear condition

A technology of cutting parameters and cutting teeth, applied in geometric CAD, electrical digital data processing, special data processing applications, etc., can solve the problems of inability to accurately predict the force change trend and wear trend of cutting teeth, and the inability to realize the performance of PDC drill bits, etc., to achieve Improve efficiency, strong adaptability, and high solution accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

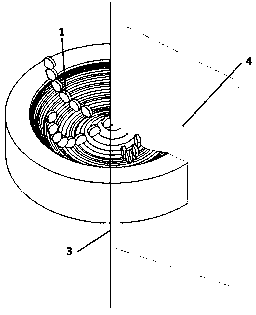

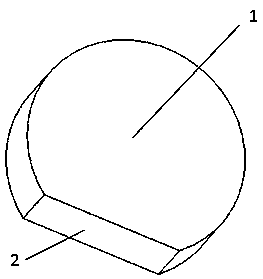

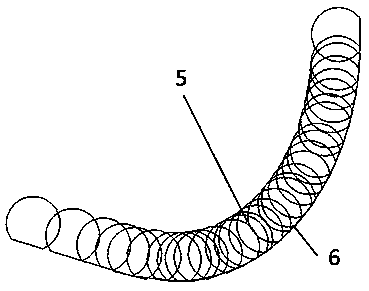

[0043] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the present invention is a method for solving the cutting parameters of PDC drill bit cutting teeth under the wear condition. The cutting parameters of the method refer to the length of the cutting arc 19, the area of the cutting section 15, and the cutting section 15 formed by rotating one circle around the central axis 3. cutting volume. The steps of the solution method are:

[0044] ① if figure 2 As shown, the geometric model of the wear tooth 1 is established, the wear tooth 1 is cylindrical, and the wear surface 2 is set as a plane.

[0045] ② if figure 1 and image 3 As shown, all the worn teeth 1 on the drill bit are rotated around the central axis 3 and projected onto the axial section 4 under the condition that the drilling speed is zero, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com