Reinforcement-truss-type floor bearing plate

A truss-type, floor-bearing slab technology, applied to floors, buildings, building components, etc., can solve problems such as easy deformation of trusses, unreasonable connection between bottom formwork and trusses, and achieve the effect of optimizing stability and improving bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

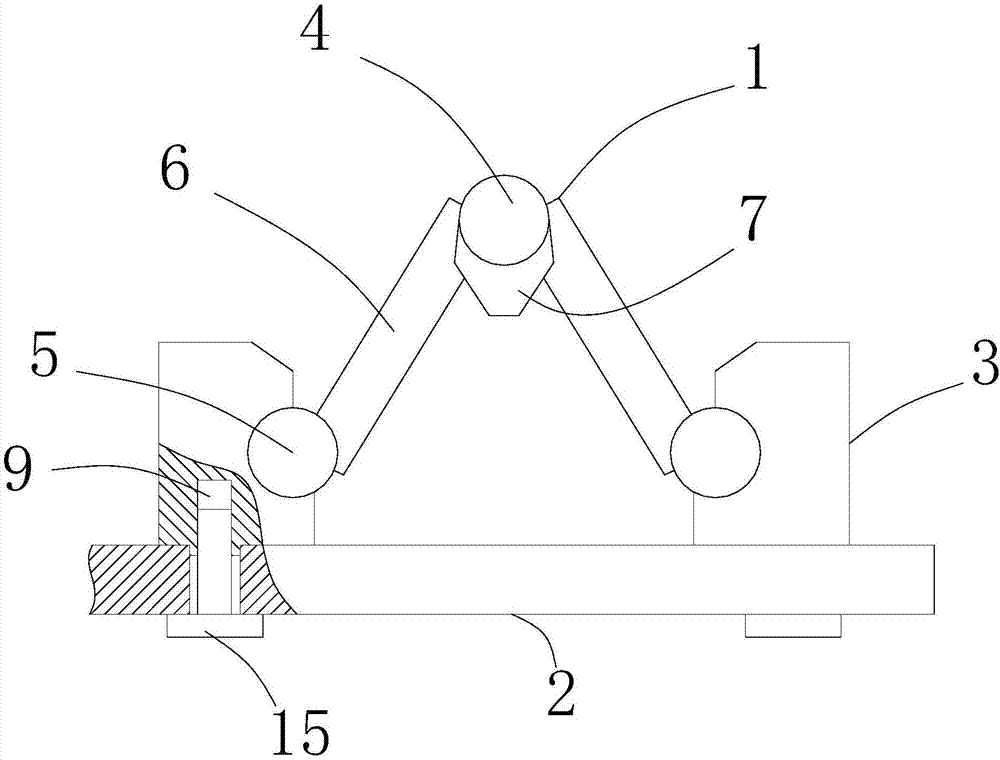

[0043] figure 1 It is the front view of a reinforced truss-type floor deck, such as figure 1 As shown, the buckle hanger 3 is mainly used to connect the bottom formwork 2 to the truss body 1, and facilitate subsequent removal of the bottom formwork 2.

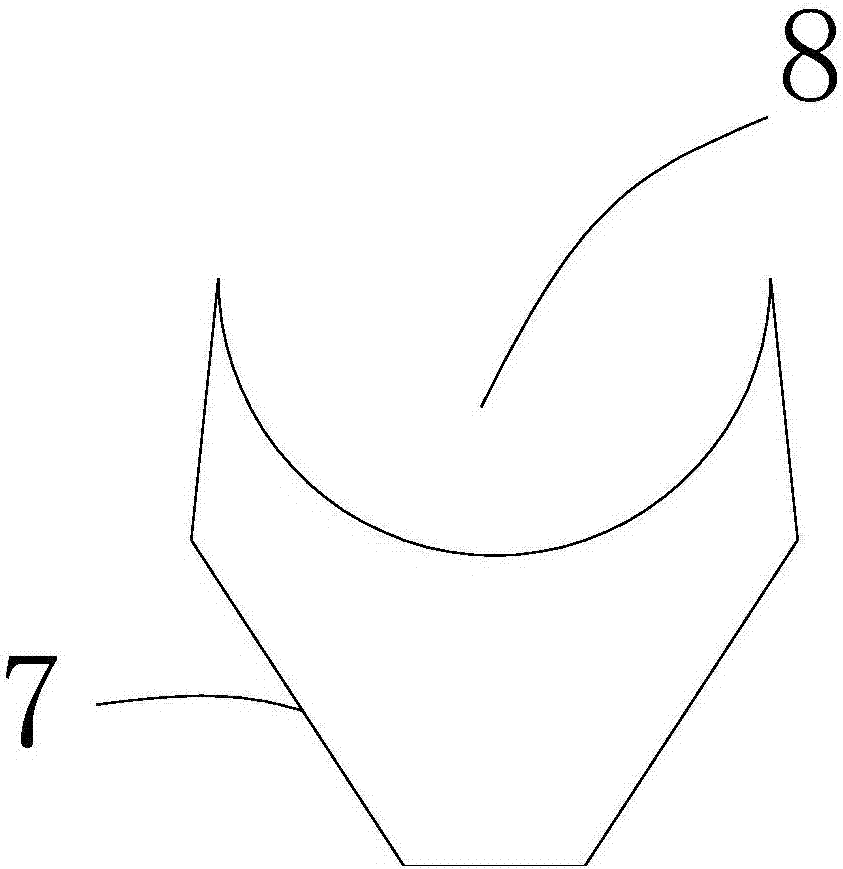

[0044] figure 2 yes figure 1 left view of the , such as figure 1 , figure 2 As shown, the truss body 1 includes the upper chord steel bar 4, the lower chord steel bar 5 and the connecting steel bar 6 connected between the upper chord steel bar 4 and the lower chord steel bar 5, and the connecting steel bar 6 should be able to produce certain elastic deformation. There are at least two lower chord steel bars 5 connected to the upper chord steel bars 4 , and a truss with two lower chord ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com