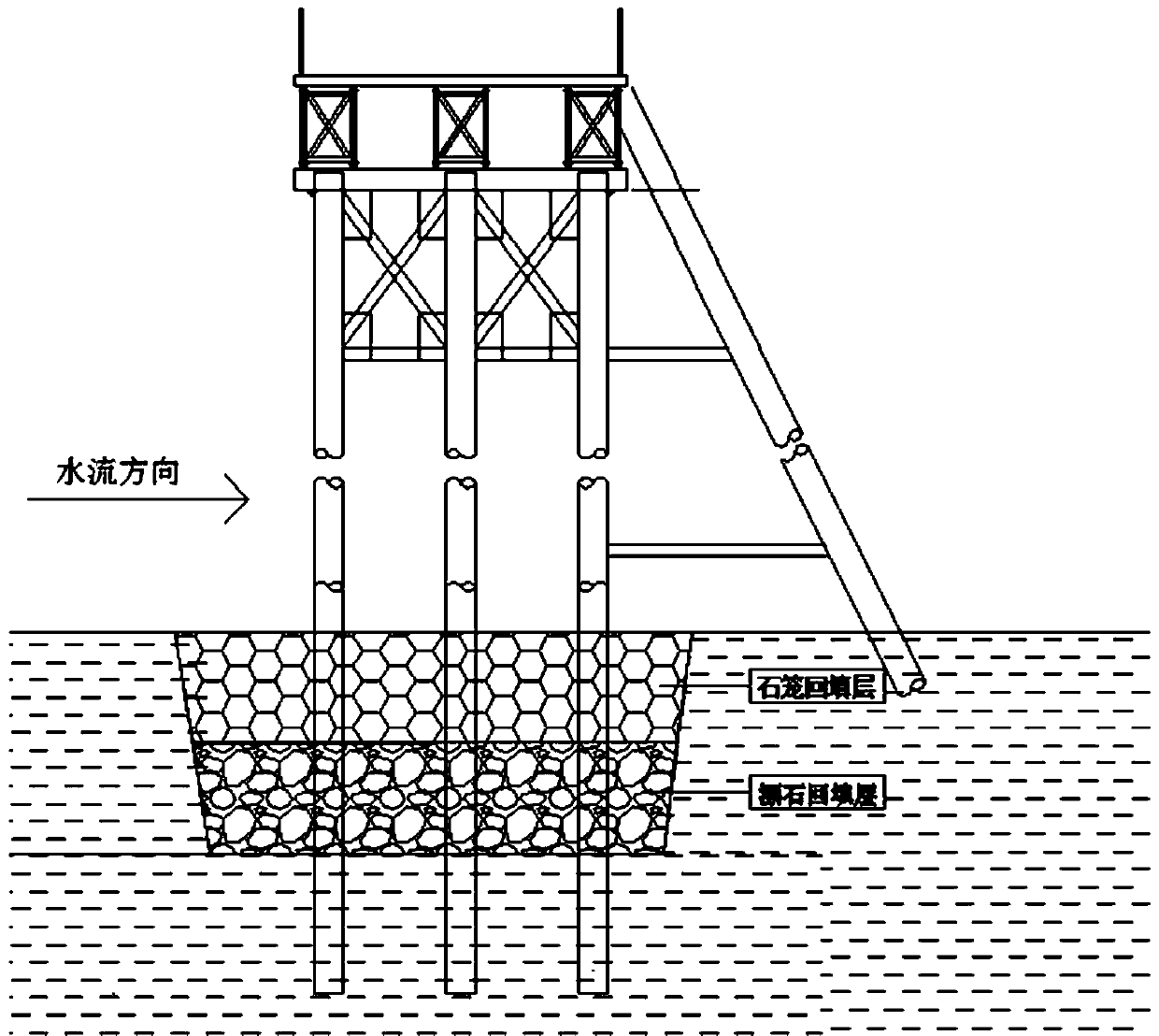

Anti-scouring construction method adopting steel trestle steel pipe piles on shallow water riverbed thick boulder covering layer

A construction method and technology of steel pipe piles, which are applied in the anti-scour field of riverbeds, can solve problems such as the inability to insert steel pipe piles, achieve the effects of improving stability and safety, reducing construction costs, and strong erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0058] The upper structure of the approach bridge on one side of a bridge adopts 7x40m first simply supported and then continuous prestressed concrete T beam, the upper structure of the main bridge adopts 70+125+125+70m prestressed concrete continuous box girder, and the upper structure of the approach bridge on the other side adopts 8×40 The first is simply supported and then the continuous prestressed concrete T-beam. The pier under the main bridge is a reinforced concrete solid wall pier, and the pier under the approach bridge is a column pier. There are 6 rows of pier columns on the river bed. bridge construction. The bridge is located about 300m downstream of a hydropower station. The river bed is covered by a pebble layer, and the covering layer is 3-7m. The descending order is strong weathered sandstone and moderately weathered sandstone. The traditional steel pipe pile construction method cannot be inserted into the bridge. Design depth, once the hydropower station flo...

Embodiment example 2

[0060] The upper structure of a certain bridge adopts 9×40m first simply supported and then continuous prestressed concrete T-beams, and the lower structure piers are column piers. The bridge is located at a location where the water flow is turbulent, and the riverbed is covered by pebbles, with a covering layer of 4-8m. According to the practice and experience of Case 1, the construction method of Case 1 is used to construct steel pipe piles for the steel trestle bridge, which greatly shortens the construction time of the steel trestle bridge. The construction period saves the construction cost, improves the anti-scouring ability of the steel trestle, and ensures the stability and safety of the steel trestle. During the construction of the bridge, the steel trestle was as stable as ever after experiencing several major flood seasons.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com