Dam slope concrete mechanical lining seam self-propelled cutting machine and use method thereof

A concrete machinery and cutting machine technology, which is applied in water conservancy projects, sea area projects, roads, etc., can solve problems such as improper cooperation between hand-operated potter's wheels and cutting machines, and achieve the effects of saving manpower, light weight, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be described in detail below to facilitate further understanding of the present invention.

[0032] All experimental methods used in the following examples are conventional methods unless otherwise specified.

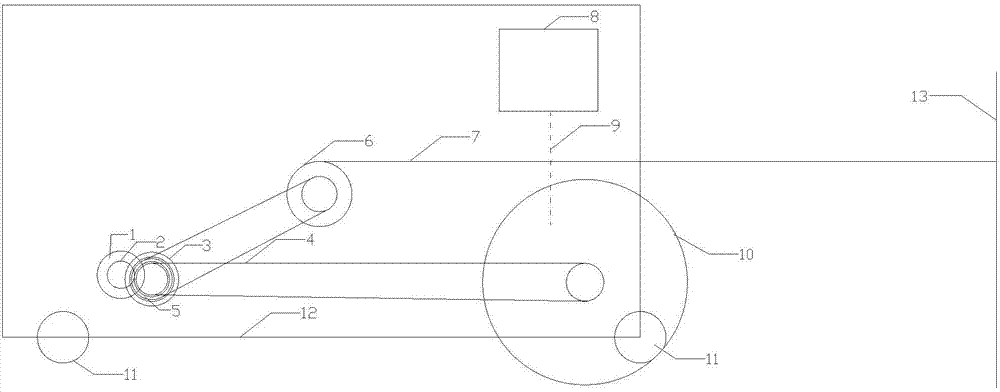

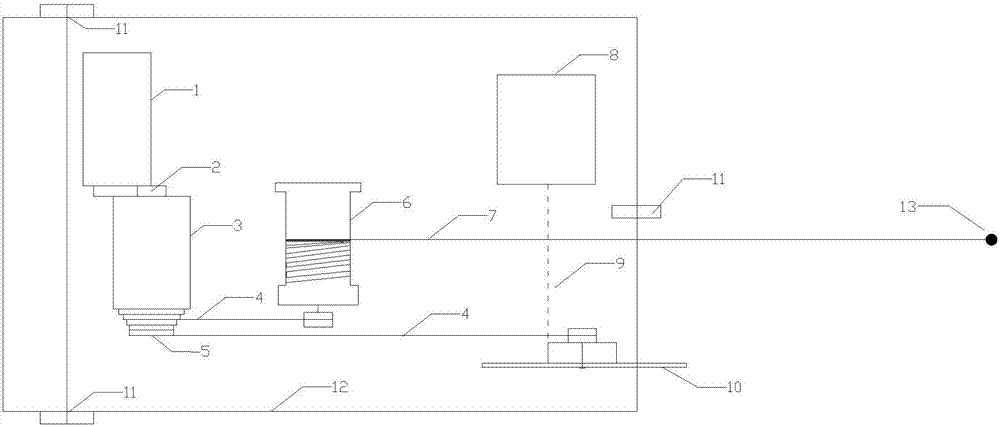

[0033] figure 1 It is a schematic front view of a self-propelled cutting machine for dam slope concrete mechanical lining joints according to the present invention. figure 2 It is a schematic top view of the self-propelled cutting machine for dam slope concrete mechanical lining joints according to the present invention. as the picture shows:

[0034] A self-propelled cutting machine for splitting joints of dam slope concrete mechanical lining includes a frame 12 and a walking wheel 11 arranged at the lower end of the frame 12.

[0035] In detail:

[0036] The frame 12 is provided with a three-phase asynchronous motor 1, an electromagnetic speed regulator 3, a hoist 6, a wire rope 7 and a cutting cutter disk 10. sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com