Left beam installing support for automobile

A technology for mounting brackets and automobiles, applied in the field of auto parts, can solve the problems of poor quality performance, low installation efficiency, low firmness, etc., and achieve the effect of simplifying processing difficulty, improving installation efficiency, and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

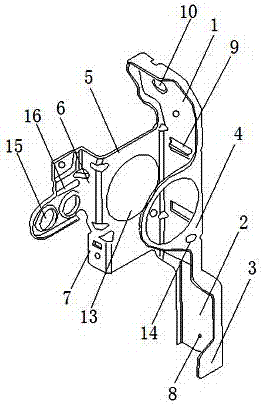

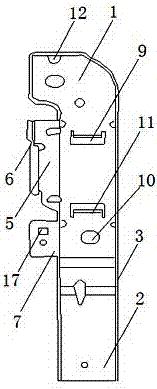

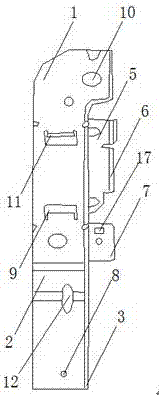

[0015] as attached Figure 1-4 Shown: a kind of crossbeam left installation bracket that is used for automobile, comprises main board one 1, main board two 2, folded edge 3, installation board one 4, installation board two 5, reinforcement board 6 and positioning board 7, it is characterized in that: Said main board-1 is provided with installation hole 8, draw-in groove 9, positioning hole 10, and described draw-in groove 9 is provided with fastening block 11, passes through draw-in groove 9 and the fastening block 11 in draw-in groove 9, facilitates The installation of the left mounting bracket of the crossbeam can improve the work efficiency and the firmness after the installation of the left mounting bracket of the crossbeam. The main board two 2 is connected with the main board one 1, and the main board two 2 is provided with a mounting hole 8. A strengthening block 12 is arranged between the main board two 2 and the main board one 1, and the folded edge 3 is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com