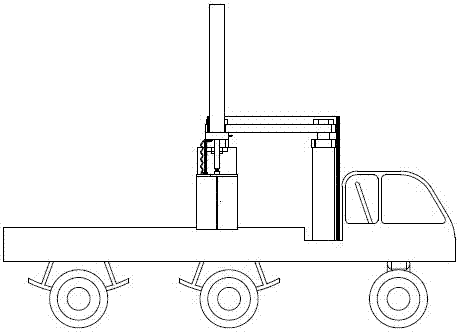

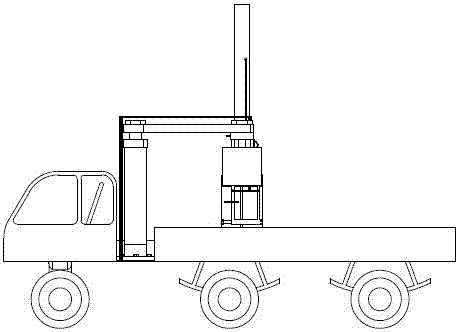

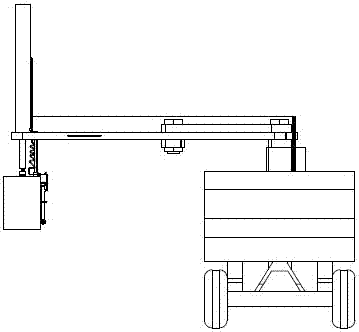

Vehicle transport automatic loading and unloading brick two oil cylinder side clamping equipment

A technology for automatic loading and unloading and clamping equipment, applied to vehicles with swing arms, etc., can solve problems such as slow speed and low work efficiency, and achieve the effects of reducing costs, improving work efficiency, and being easy to promote and popularize.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Example: refer to Figure 9 , Figure 10 , Figure 11 and Figure 12 As shown, the vehicle transportation automatic loading and unloading brick two cylinder side clamping equipment is characterized in that the oil separation controller 15 is installed on the top of the brick clamping steel plate, and the handle 1 is installed on the brick clamping steel plate one. The button of the oil controller 15, according to the different positions of the brick stack, is grasped on the handle 1 to adjust the entry position of the brick that needs to be pushed horizontally. Button, under the action of oil pressure, hydraulic lever 2 and hydraulic lever 3 push the brick clamping steel plate 1 and brick clamping steel plate 2 to move outward. A proper amount of adjustment can increase the gap between the bricks. After proper adjustment, grasp the Continue to move to the inner side on the handle 1. When the rear side of the brick clamping steel plate 1 and the brick clamping steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com