Wheel mechanism for testing trolley chassis of remotely piloted vehicle

A technology of unmanned vehicles and wheels, which is applied in vehicle testing, machine/structural component testing, vehicle springs, etc., can solve problems such as waste of social resources and reduce the service life of the test car chassis, so as to prolong the service life and reduce the The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The preferred embodiments are given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

[0052] Combine below Figure 1 to Figure 18 , the chassis of the unmanned vehicle test car of the present invention is described in detail.

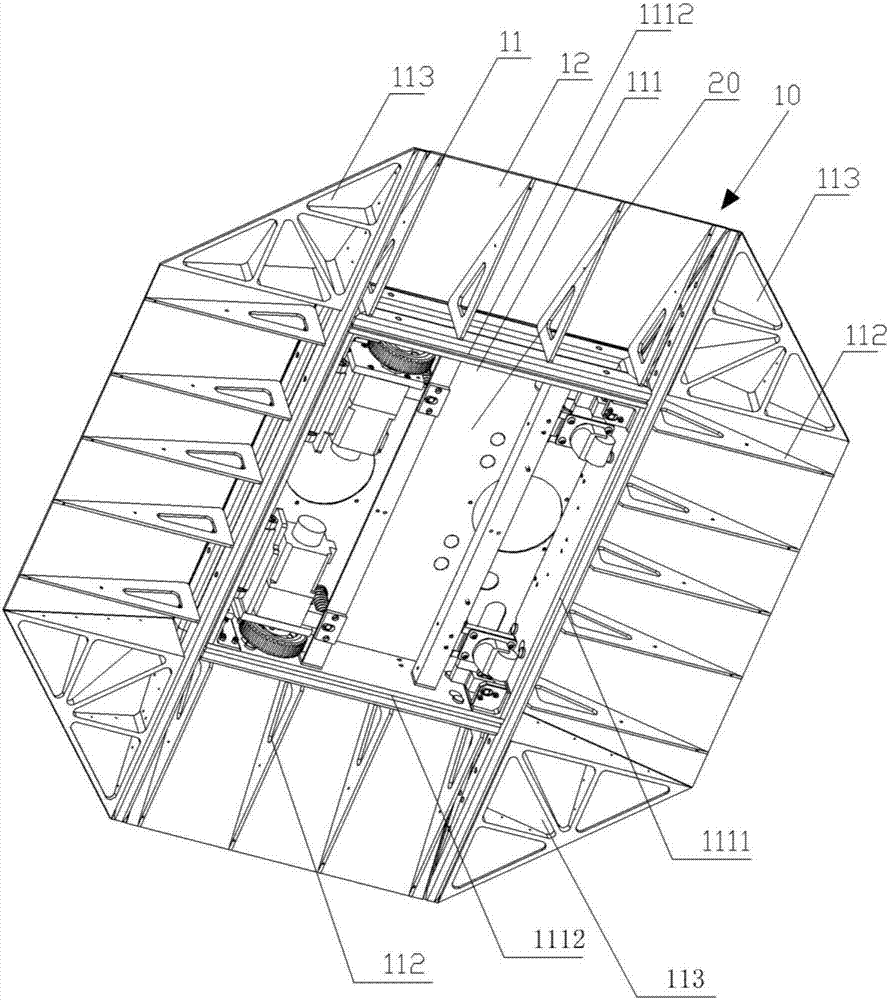

[0053] Such as figure 2 As shown, the chassis of the unmanned vehicle test car in this embodiment has a section of Type chassis main body mechanism 10 and the wheel mechanism 20 that is fixedly connected with the inner surface of chassis main body mechanism 10 .

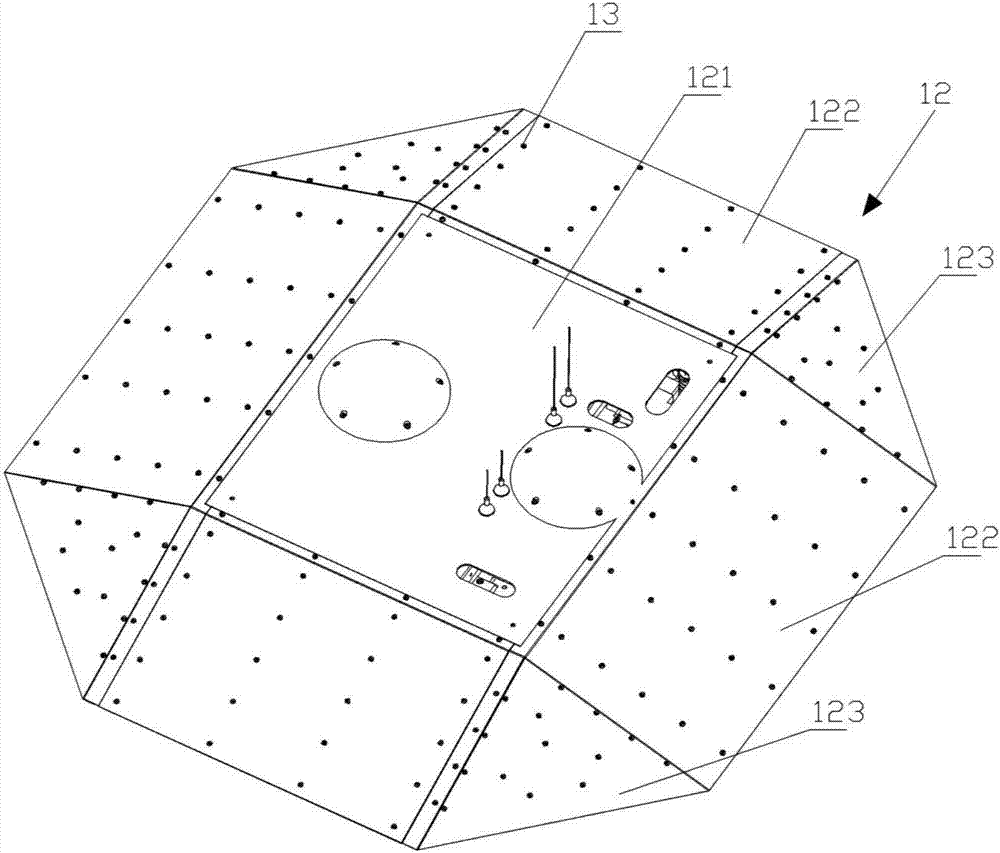

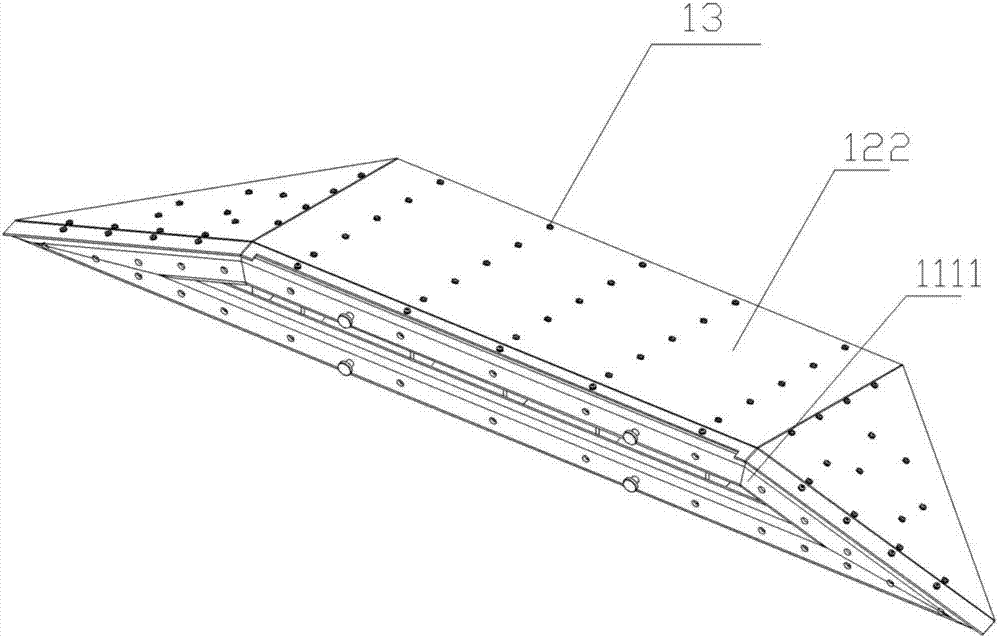

[0054] Such as figure 1 and figure 2 As shown, the chassis main body mechanism 10 has a chassis main body 11 and a cover on the upper surface of the chassis main body 11 Type chassis shell 12. The chassis shell 12 is fixedly connected to the chassis body 11 via several fasteners 13 . The chassis body 11 has a chassis bracket 111 located below the center of the inner surface of the chassis shell 12 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com