Dust-free damping cutting equipment for building pipes

A kind of cutting equipment and technology for construction, which is applied in the field of dust-free cutting equipment for construction pipes, can solve the problems of high hazard, high noise between the device and the ground, and inability to absorb shocks, so as to avoid iron filings scattered, easy to move, and structurally simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

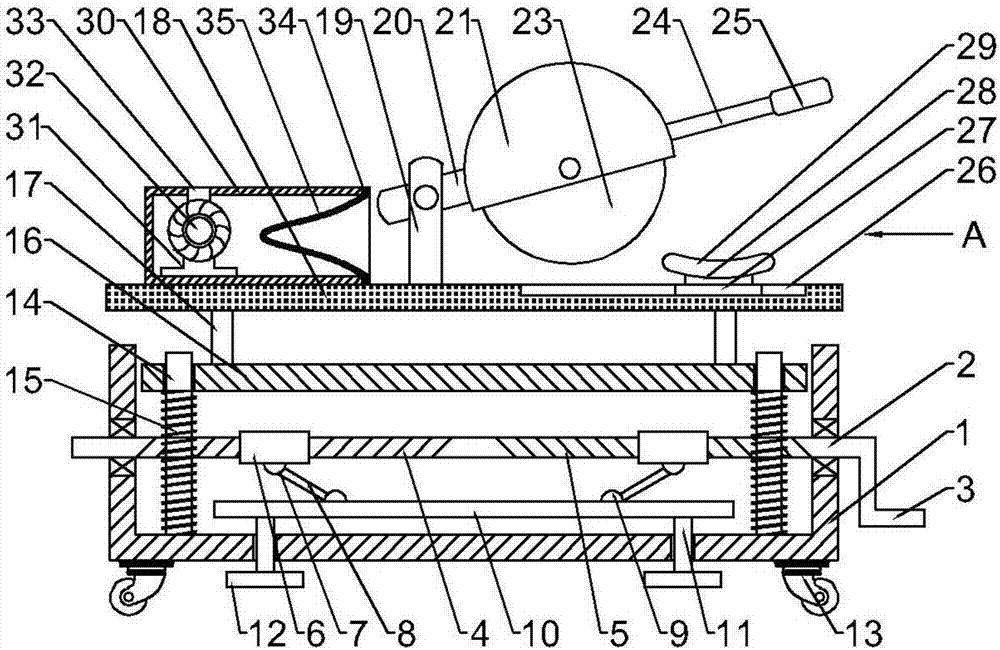

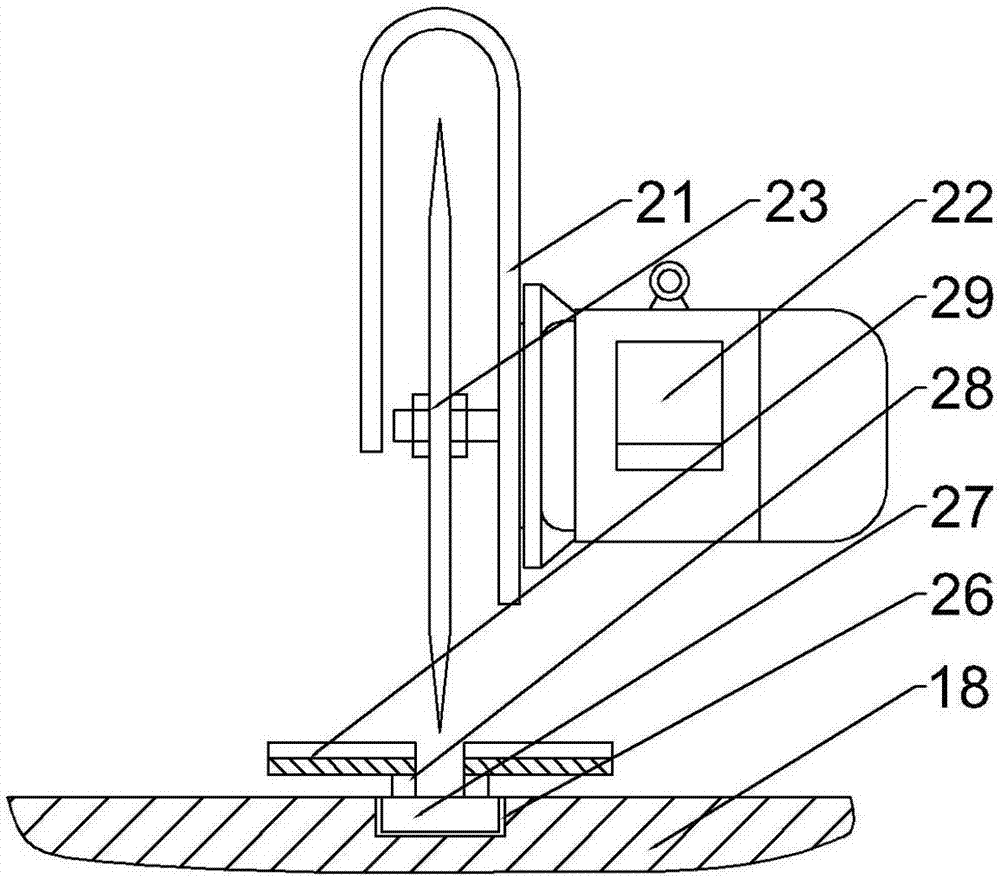

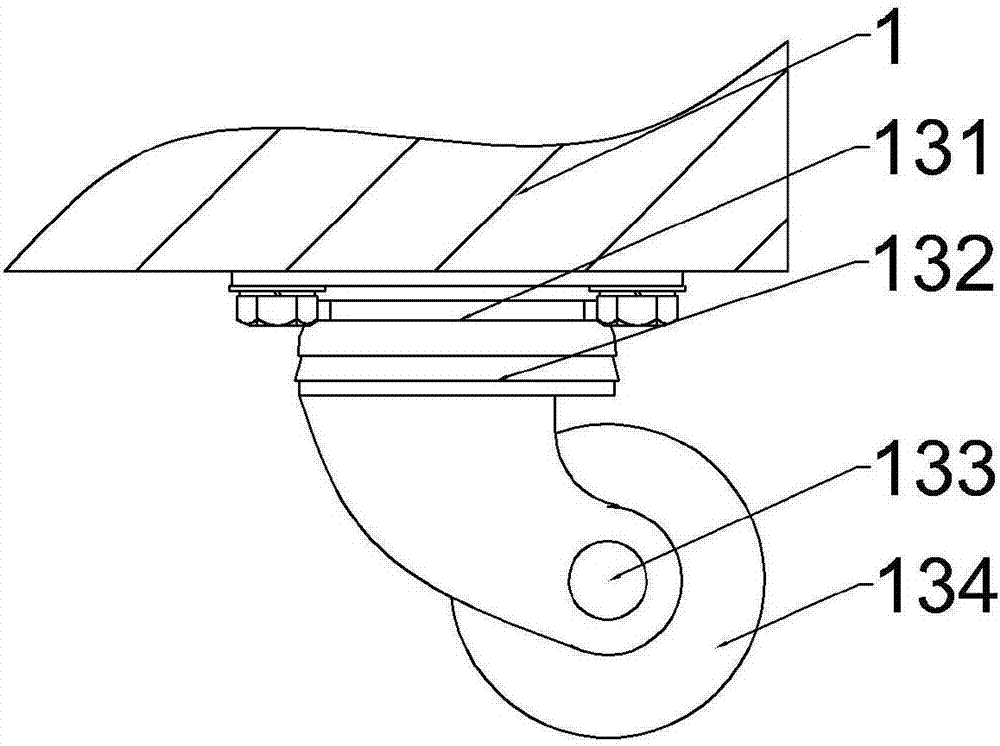

[0021] see Figure 1-3 , a dust-free cutting equipment for building pipes with a shock-absorbing function, comprising a support base 1, the middle part of the support base 1 is connected to a horizontal rotating rod 2 through bearing rotation, and the left end of the horizontal rotating rod 2 is fixedly connected to a left thread 4 , the right end of the horizontal rotating rod 2 is fixedly connected with a right thread 5, and the left thread 4 and the right thread 5 have opposite helical directions, and the left thread 4 and the right thread 5 are all threaded in the middle of the outer side with a sliding sleeve 6, and the lower sides of the sliding sleeve 6 are fixed. Connected with a first rotary hinge 7, the lower side of the first rotary hinge 7 is fixedly connected with a tilting link 8, and the lower side of the tilting link 8 is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com