Gel extinguishing material mixer

A technology of fire extinguishing materials and mixers, which is applied in fire rescue and other fields, can solve problems such as uneven mixing of mixers, and achieve the effects of solving uneven mixing, convenient operation and use, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

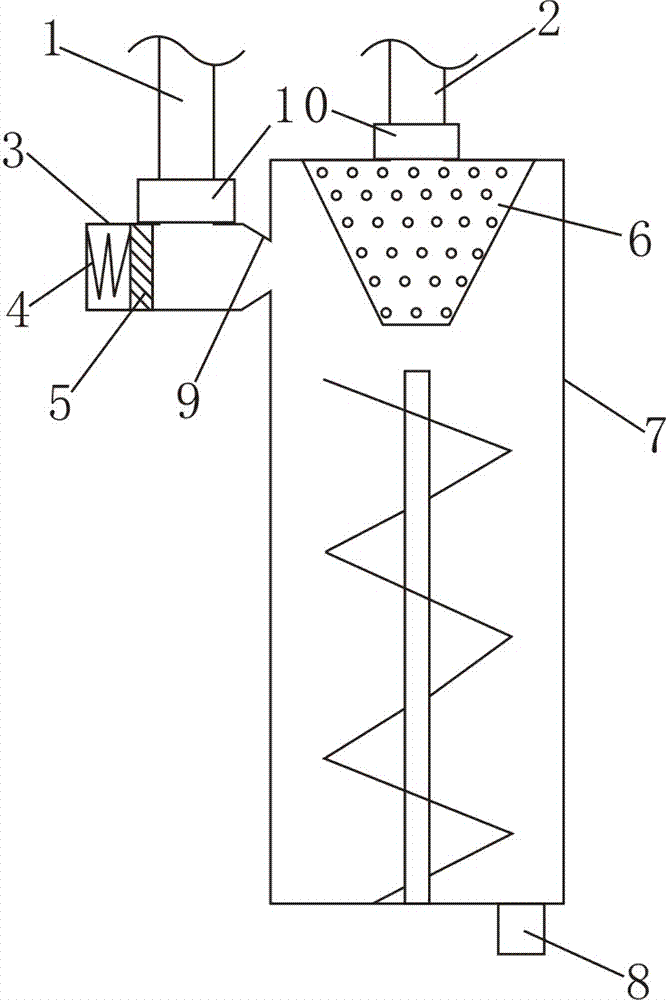

[0012] Now refer to the attached figure 1 , combined with the embodiment description as follows: a gel fire extinguishing material mixer, including a mixing chamber body 7, a feed pipe A1 and a feed pipe B2, the top of the mixing chamber body 7 is provided with a feed pipe B2, the mixing chamber The bottom end of the body 7 is provided with a feeding pipe 8, which is characterized in that a one-way valve 10 is screw-connected to the contact part between the feeding pipe B2 and the mixing chamber body 7, and the upper end of the mixing chamber body 7 is integrally provided with a stagnation valve. Cavity B6, the retention cavity B6 communicates with the feed pipe B2, the surface of the retention cavity B6 is uniformly arranged with drip holes, and the upper end of the mixing chamber body 7 is integrally equipped with a retention cavity A3, The retention chamber A3 communicates with the mixing chamber body 7, and the middle of the retention chamber A3 communicates with the feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com